+86 180 0293 5268

+86 180 0293 5268

Lost Wax Investment Casting has become an indispensable technique in various industries, particularly in aerospace and automotive sectors, where precision and quality are paramount. According to a report by Market Research Future, the global market for lost wax investment casting is projected to reach USD 16.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.8% from 2019 to 2025. This upward trend is largely driven by the increasing demand for high-performance components that require intricate designs and superior surface finishes, which only this technique can offer.

As industry expert Dr. Emily Carter, a renowned specialist in advanced casting methods, notes, “Lost Wax Investment Casting provides unparalleled accuracy and versatility, making it a preferred choice for manufacturers seeking to produce intricate components with tight tolerances.” This statement underlines the importance of embracing modern advancements in lost wax techniques that not only enhance efficiency but also reduce material waste. With ongoing innovations in materials and technologies, the lost wax casting process is evolving, offering even greater benefits and opening new avenues for application in sectors like medical devices and art.

As we navigate through this comprehensive guide, we will delve into the various techniques of Lost Wax Investment Casting, explore the associated benefits, and examine the diverse industry applications that showcase its capabilities in meeting contemporary manufacturing demands.

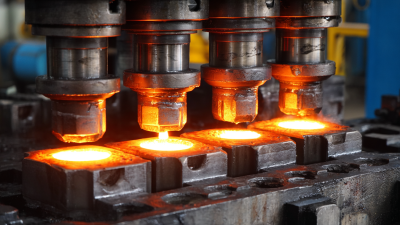

Lost wax investment casting is a highly sophisticated process, renowned for its exceptional ability to create intricate and precise metal components. This technique involves creating a wax model of the desired part, which is then encased in a ceramic shell. Once the shell hardens, the wax is melted away, leaving a hollow mold into which molten metal is poured. This process allows for the production of parts with complex geometries and fine details, making it ideal for various industries, especially automotive, where precision is crucial.

In recent developments, the quality control of investment casting has been enhanced through the integration of advanced technologies. Innovations such as blockchain-driven IoT devices are being utilized for real-time inspection of casting defects, ensuring greater accuracy and traceability in the manufacturing process. These advancements address longstanding challenges in defect detection, further solidifying lost wax investment casting as a preferred method for creating high-quality and durable components in modern industrial applications.

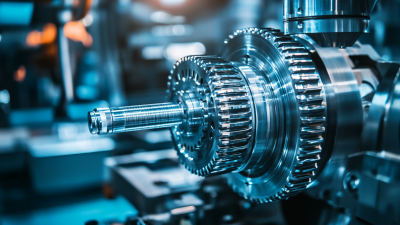

Lost wax investment casting, also known as precision casting, offers numerous advantages in modern manufacturing. One of the key benefits is the exceptional accuracy and detail it provides, allowing for complex geometries that are often impossible to achieve with traditional casting methods. This level of precision reduces the need for extensive machining, minimizing material waste and overall production costs. Additionally, lost wax casting supports a wide range of materials, including metals and alloys, making it versatile for various industries such as aerospace, automotive, and art.

Lost wax investment casting, also known as precision casting, offers numerous advantages in modern manufacturing. One of the key benefits is the exceptional accuracy and detail it provides, allowing for complex geometries that are often impossible to achieve with traditional casting methods. This level of precision reduces the need for extensive machining, minimizing material waste and overall production costs. Additionally, lost wax casting supports a wide range of materials, including metals and alloys, making it versatile for various industries such as aerospace, automotive, and art.

Tips: When considering lost wax investment casting, selecting the right wax and mold materials is crucial for achieving optimal results. Ensure thorough communication with your casting provider about your design specifications to avoid any potential discrepancies during the manufacturing process.

Another significant benefit is the surface quality that this method can yield. The smooth finishes obtained through lost wax casting can eliminate the necessity for post-casting polish, which further streamlines production. This technology also allows for the production of smaller batch sizes, making it ideal for custom components and specialized applications, thus empowering businesses to innovate and adapt quickly to market demands.

Tips: When preparing your designs, focus on uniform wall thickness to enhance both the casting process and final product performance. Regularly review your designs for manufacturability to take full advantage of the lost wax method.

Lost wax investment casting is a versatile manufacturing technique that finds wide-ranging applications across multiple industries. In the aerospace sector, for example, this precise casting method is utilized to create complex components such as turbine blades and structural parts that require exceptional strength-to-weight ratios. The ability to produce intricate shapes with tight tolerances makes lost wax investment casting indispensable for meeting the demanding specifications of aerospace engineering.

Similarly, the automotive industry leverages this technique to manufacture high-performance engine components and intricate assembly parts. The process allows for the production of lightweight yet durable components that enhance the efficiency and performance of vehicles. Additionally, the medical sector benefits from lost wax investment casting in creating high-precision instruments and implants, where accuracy and biocompatibility are paramount. This adaptability across diverse applications illustrates the critical role of lost wax investment casting in driving innovation and efficiency in various industries.

Lost wax investment casting, a time-honored process, continues to evolve as technology advances. With the latest innovations in casting simulations, visual tools can enhance the detection of porosity in cast products. This is crucial, as porosity can significantly affect the mechanical properties and integrity of the final product. According to recent industry reports, addressing porosity issues early in the design phase can result in a 20-30% reduction in production costs, emphasizing the importance of precision in the casting process.

To optimize the lost wax investment casting process, it's essential to adopt cutting-edge techniques. One effective tip is the implementation of advanced computer-aided engineering (CAE) tools that enable the precise design of casted parts. This not only improves the performance characteristics of the final products but also streamlines the workflow by minimizing errors and enhancing efficiency. Additionally, exploring water-free die release technologies can further enhance productivity and quality levels in both investment and die casting processes.

Another strategy involves the use of topologically optimized designs, particularly in heavy-duty applications. By innovating with cast glass elements that have reduced annealing times, manufacturers can ensure that performance is not compromised by lengthy production processes. Such forward-thinking approaches can lead to more robust and reliable components, setting a new standard in the casting industry.

The landscape of lost wax investment casting is undergoing significant transformation, driven by innovative technologies and a growing emphasis on sustainability. As the jewelry industry aligns with eco-friendly practices, there is a notable shift toward integrating artificial neural networks to optimize eco-design. This approach not only improves efficiency but also supports sustainable manufacturing practices, ensuring that the industry meets both environmental and consumer demands.

Tips: Embrace technology in your design processes. Utilizing advanced modeling tools can help predict the environmental impact of materials and designs before production begins.

Moreover, as investment casting technology evolves, additive manufacturing is pushing the boundaries of traditional methods. Techniques such as sinter-based technologies are being explored to create intricate designs while reducing waste. This trend highlights the importance of resource efficiency and climate protection, essential components for future industry practices.

Tips: Stay updated on the latest trends in additive manufacturing. Participating in industry events and conferences can provide valuable insights into innovative technologies reshaping investment casting.