+86 180 0293 5268

+86 180 0293 5268

The metal parts manufacturing industry is rapidly evolving. As we look towards 2026, it is clear that trends emphasizing efficiency will dominate this sector. According to a recent report by the Industrial Manufacturing Institute, 75% of companies are investing in advanced technologies to streamline production processes. This shift is driven by the need for higher precision and reduced costs.

Experts like Dr. Emily Carter, a leading authority in metal parts manufacturing, emphasize the importance of innovation. She states, "Embracing new technologies is not just an option; it’s essential for survival in the competitive landscape." Companies are increasingly adopting automation and AI to enhance productivity. These tools not only improve output but also minimize human error.

However, challenges remain. Many manufacturers struggle with integrating new systems into existing workflows. As a result, the journey towards enhanced efficiency in metal parts manufacturing is not without its hurdles. The commitment to evolve must be paired with an openness to address these growing pains, ensuring a balanced approach to modernization.

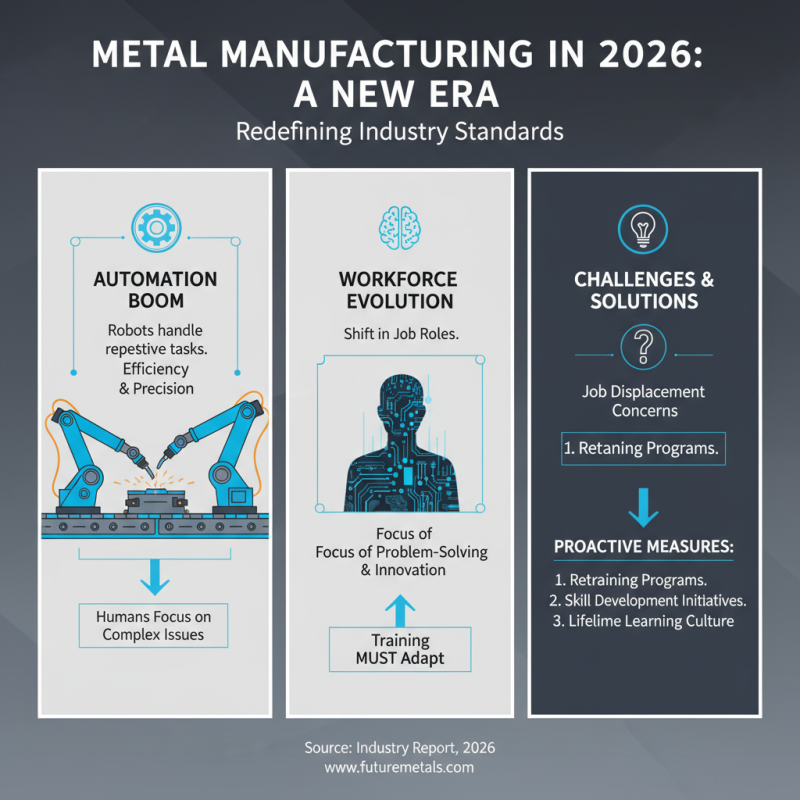

In 2026, innovations in metal parts manufacturing technology promise to redefine industry standards. One notable advancement is the increased use of automation. Robots are taking on repetitive tasks, allowing human workers to focus on complex issues. However, this shift raises questions about job displacement. Training programs must adapt quickly to ensure the workforce remains relevant.

Additive manufacturing is another key trend. This process enables the creation of intricate designs that were once impossible. It reduces material waste and speeds up production. Nonetheless, not all materials integrate well with additive techniques, leading to a need for ongoing research. Testing various options can be time-consuming but is essential for maximizing efficiency.

Sustainability is gaining traction, too. More manufacturers are exploring eco-friendly materials and processes. While this is a positive step, the transition can be slow. There are still hurdles in sourcing sustainable materials without compromising quality. Each innovation comes with its challenges, requiring careful consideration and planning. The future of metal parts manufacturing is bright but fraught with complexities.

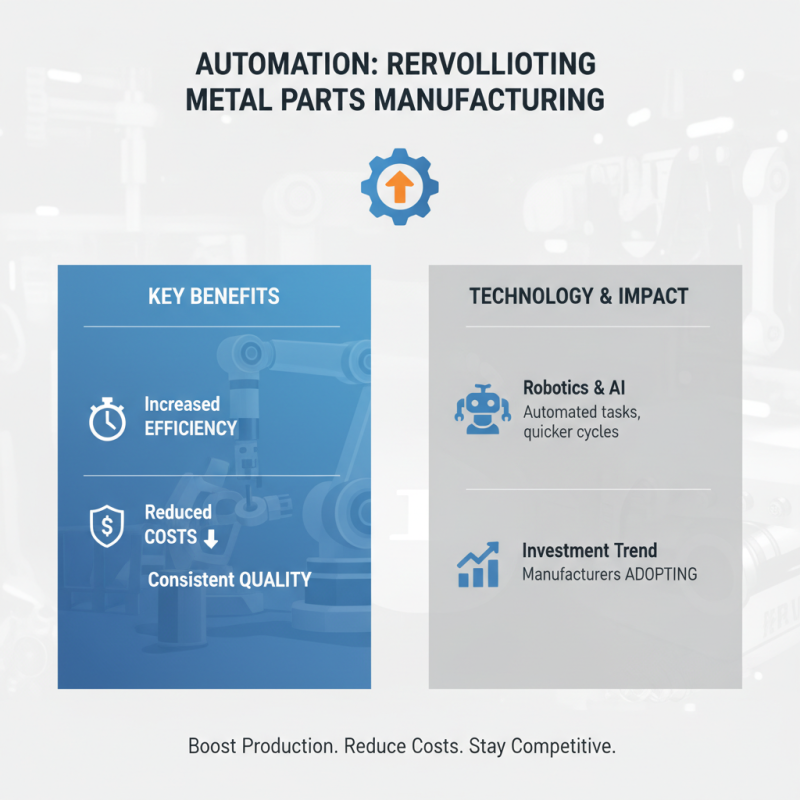

Automation is revolutionizing metal parts manufacturing. It's crucial for boosting production efficiency and reducing costs. Many manufacturers are investing in automated technologies. Robots are now handling tasks that once required manual labor. This leads to quicker production cycles and consistent quality.

Tips: Regularly evaluate automation needs. Not all processes are suitable for robots. Sometimes, a hybrid approach might work better.

While automation has benefits, challenges exist. Initial investment costs can be high. There may also be resistance from workers fearing job loss. Balancing technology with workforce needs is essential. It’s about enhancing skills alongside automation.

Tips: Provide training programs for employees. This can help them adapt to new roles in an automated environment. Encourage open discussions about technology's role in the workplace.

The adoption of advanced materials in metal parts manufacturing is reshaping the industry. Lightweight and durable materials, such as titanium alloys and advanced composites, enhance performance while reducing energy consumption. According to a report by MarketsandMarkets, the metal parts manufacturing sector is expected to grow by 7.5% yearly through 2026. This trend aligns with the increasing demand for efficient production methods.

In addition to improving performance, using advanced materials can sometimes lead to challenges. For instance, the cost of these materials can be significantly higher than traditional options. A study by Deloitte found that companies may need to invest up to 20% more in R&D to effectively integrate these materials into existing processes. This investment could strain budgets, especially for smaller manufacturers.

Moreover, not all advanced materials perform well in every application. The mechanical properties can vary widely based on production techniques. This variability can lead to unexpected failures and necessitates further testing and validation. Industry experts recommend a meticulous evaluation of material properties before adoption, ensuring that the benefits outweigh potential risks. As manufacturers navigate this landscape, ongoing learning and adjustment will be crucial for sustained success.

The integration of the Internet of Things (IoT) into metal parts manufacturing is transforming the industry. Real-time monitoring is now possible through sensors that collect data on every aspect of production. Machines can communicate their status, alerting operators to issues before they escalate. This immediacy allows for quicker decision-making, but it can also present challenges.

For instance, not all companies are equipped to handle the influx of data. As manufacturers adopt these technologies, the sheer volume of information can be overwhelming. Employees must be trained to interpret this data effectively. Without proper training, the benefits of IoT can be lost. Moreover, security concerns arise with the increased connectivity of machines. Cybersecurity threats could potentially compromise sensitive production data.

Despite these challenges, the potential advantages of adopting IoT are significant. Predictive maintenance can reduce downtime, improving overall efficiency. Machines that can self-diagnose issues help prevent costly disruptions. However, the complexity of implementing such systems requires careful planning and consideration. Manufacturers need to reflect on their infrastructure before fully embracing IoT solutions.

This chart illustrates the integration of IoT in metal parts manufacturing over the years 2023 to 2026, focusing on the percentage increase in efficiency achieved through real-time monitoring capabilities.

Sustainability is essential in metal manufacturing. Recent reports show that nearly 30% of global waste comes from the production of metal parts. This statistic indicates a pressing need for improved practices. Companies are shifting towards recycling metals, with over 70% of manufacturers now using recycled materials. This change not only reduces waste but also lowers energy consumption.

Energy efficiency is another vital aspect. According to industry data, organizations can cut energy use by 15% through advanced manufacturing technologies. Techniques like additive manufacturing and precision machining offer better energy performance. However, implementation can be challenging. Many companies still struggle with outdated machinery that consumes excessive power. This gap highlights the importance of investing in modern energy-efficient solutions.

Furthermore, the industry faces a significant dilemma. While striving for sustainability, there’s pressure to meet high production demands. Balancing these needs can feel overwhelming. Developing a clear strategy is necessary to navigate this challenge effectively. The road to enhanced efficiency in metal manufacturing must involve continuous evaluation and adjustment of practices.

| Trends | Description | Impact on Efficiency | Sustainability Benefits |

|---|---|---|---|

| Additive Manufacturing | Utilizing 3D printing technology to create complex metal parts. | Increases production speed and flexibility. | Reduces material waste significantly. |

| Automation & Robotics | Integration of robots in manufacturing processes. | Improves precision and reduces labor costs. | Enhances energy efficiency through optimized operations. |

| Digital Twins | Virtual simulations of machines and processes to predict outcomes. | Allows for proactive maintenance and reduces downtime. | Helps in minimal energy consumption during operations. |

| Recycling of Metal Scraps | Processes metal waste back into usable material. | Reduces the cost of raw materials. | Lowers the carbon footprint of the manufacturing process. |

| Energy-efficient Machinery | Investing in machines that consume less energy. | Decreases overhead costs in production. | Minimizes overall environmental impact. |