+86 180 0293 5268

+86 180 0293 5268

In the evolving landscape of manufacturing, Cnc machined parts stand as a beacon of innovation. Experts in the field, like Dr. Emily Carter, have noted, "The future of Cnc machined parts lies in adaptability." This insight highlights the importance of staying ahead in design and technology.

As we explore the trends shaping 2026, we notice a shift toward automation and customization. Manufacturers are investing in advanced CNC machines. These machines offer precision while reducing waste. It's fascinating yet challenging. There is pressure to innovate rapidly.

Additionally, sustainability is a theme becoming more pronounced. Companies face a dilemma. They must balance costs and environmental impact. The journey is not without hurdles. While advancements are impressive, some techniques may need refinement. The need for continuous improvement remains ever-present in the Cnc machined part industry.

The CNC machining industry is witnessing transformative trends, particularly in material innovation. Emerging materials designed to enhance performance are gaining traction. A recent industry report indicated that the demand for advanced materials in CNC machining is projected to grow by 23% over the next five years. This shift highlights the need for manufacturers to adapt.

One notable trend is the increased use of composites. Composites offer high strength-to-weight ratios, making them ideal for industries like aerospace. In the automotive sector, however, there is a challenge. While composites improve fuel efficiency, their machining requires specialized skills and tools. Many manufacturers struggle with the transition, leading to production delays.

Another innovative material is titanium alloys. Although they provide superior performance in extreme environments, they also present complexities in machining. The hard nature of titanium increases tool wear, which can slow production. The learning curve for effectively using these materials raises concerns regarding overall efficiency. These emerging materials signal a significant change in the CNC machining landscape, yet underscore the ongoing challenges that need to be addressed.

| Material | Performance Advantage | Applications | Trends |

|---|---|---|---|

| Titanium Alloys | High strength-to-weight ratio | Aerospace, Medical Implants | Increasing use in aerospace |

| Carbon Fiber Composites | Superior stiffness and lightweight | Automotive, Sporting Goods | Growing demand in lightweight parts |

| Aluminum Alloys | Good machinability and corrosion resistance | Consumer Electronics, UAVs | Sustainability in manufacturing |

| Stainless Steel | Excellent mechanical properties | Medical Devices, Food Processing | Focus on hygiene and durability |

| Polymer Matrix Composites | Versatile and lightweight | Consumer Products, Electronics | Increased adoption for complex geometries |

Automation and AI are reshaping CNC machining processes. These technologies increase efficiency and precision. Automated systems can run machines with minimal human intervention. This reduces labor costs and enhances productivity. As machines communicate, they adapt in real-time to changing conditions. Operators can monitor multiple machines from a single location, making workflow more efficient.

Yet, challenges remain. Implementing AI requires significant investment. Training for operators is essential to maximize these innovations. Some may resist change, fearing job loss. Balancing automation and human skills is crucial. While machines can enhance production speed, the human touch is vital for quality assurance. The integration of AI should be gradual, ensuring workers are onboard.

Moreover, data security is a concern. With increased connectivity, risks can arise. Protecting sensitive information is paramount. CNC machining leaders must prioritize cybersecurity as they embrace these advancements. The path forward is filled with opportunities and hurdles alike. The future of CNC machining depends on strategic innovations and thoughtful implementation.

This chart illustrates the projected trends and innovations in CNC machining processes for 2026, focusing on the adoption of automation and AI technologies.

Sustainability is transforming the CNC machining landscape. As manufacturers face increasing pressure to reduce their environmental footprint, eco-friendly practices are gaining momentum. According to a report from the World Economic Forum, embracing sustainable methods can lower energy consumption by 20-30%.

One of the most promising innovations involves recycling materials. Studies show that recycled aluminum, for example, can save 95% of the energy needed to produce new aluminum. This practice not only conserves resources but also reduces waste significantly. However, challenges remain. Many facilities lack effective recycling systems, leading to missed opportunities for sustainability.

Another trend is the use of biodegradable lubricants. These alternatives can minimize the harmful effects on ecosystems. Research indicates that adopting such practices can lead to a 50% reduction in toxic waste. Still, many manufacturers hesitate to shift. The upfront costs and the need for process adjustments often slow progress. Balancing performance and sustainability is not straightforward, and the industry must continue to innovate and reflect on its practices.

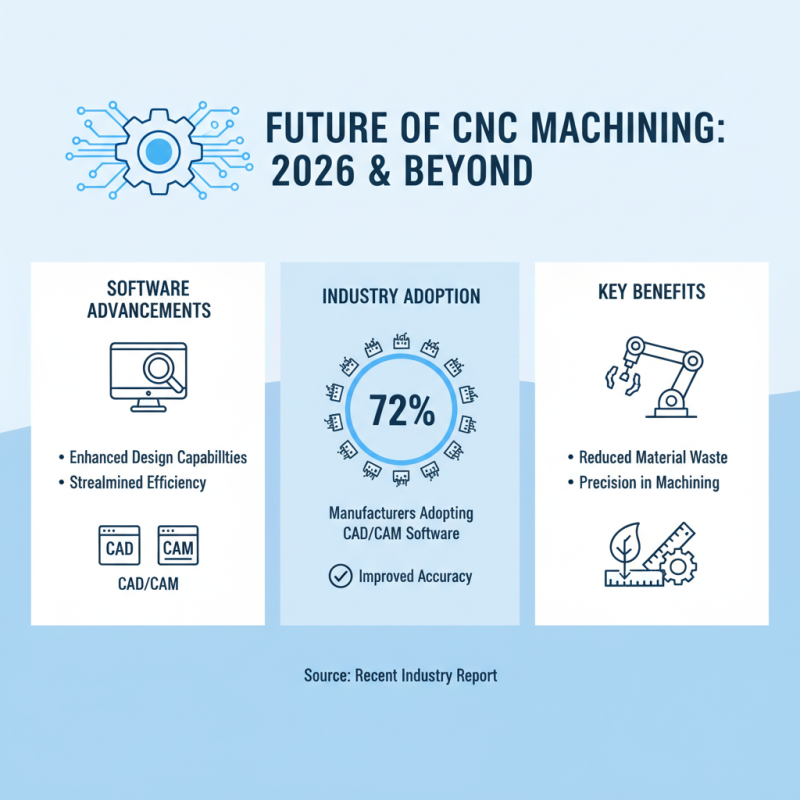

In 2026, CNC machining will greatly benefit from advanced software solutions. These technologies enhance design capabilities and streamline efficiency. A recent industry report indicates that 72% of manufacturers are adopting CAD and CAM software for improved accuracy. This adoption helps reduce material waste significantly. Such advancements lead to precision in machining processes.

Automation plays a crucial role in these innovations. Software can now simulate machining operations. This feature allows engineers to foresee potential issues before production. According to recent findings, these simulations can reduce errors by up to 50%. While these tools provide great advantages, they also require users to adapt quickly. Training may be necessary for optimal use.

**Tip:** Regularly update your software to access the latest features and improvements.

Another aspect is data analytics integration in CNC systems. Analyzing real-time data can enhance decision-making. Yet, many companies still struggle with data management. It’s essential to invest time in learning how to best utilize software capabilities.

**Tip:** Consider cross-training your team. This promotes a deeper understanding of different software platforms and enhances overall efficiency.

Personalization in CNC machining is increasing. As industries evolve, so do customer needs. Companies now seek unique solutions tailored to specific applications.

Custom CNC machining offers flexibility like never before. This allows businesses to create parts that fit their exact specifications.

It’s a game-changer in manufacturing.

The shift towards individualized designs is exciting but comes with challenges. Not every manufacturer can meet these demands effectively. Some struggle with adapting their technology. Others may lack the creative resources required for unique projects.

Ensuring quality while personalizing designs is crucial. Mistakes can lead to wasted materials and time.

Customers are pushing for faster delivery. They want quality personalized parts quickly. Companies must find a way to balance speed with uniqueness. This is where innovation plays a key role. Emerging technologies can help streamline processes. However, adaptation is not always perfect.

Continuous learning and improvement are essential for success in this landscape.