+86 180 0293 5268

+86 180 0293 5268

The aerospace industry is undergoing a monumental transformation, driven by rapid advancements in technology and a growing demand for efficiency and precision. A report from MarketsandMarkets projects that the global aerospace machining market will reach $12.25 billion by 2025, expanding at a CAGR of 5.21% during the forecast period.

Innovations in Aerospace Machining are at the forefront of this evolution, integrating cutting-edge processes like additive manufacturing, artificial intelligence, and advanced materials to enhance productivity and reduce waste. As the industry pivots towards sustainable practices and high-performance capabilities, the synergy between traditional machining techniques and modern digital solutions promises to reshape the future of aviation.

This blog will explore the pivotal innovations currently shaping Aerospace Machining and the compelling reasons why they are essential for meeting the needs of tomorrow's skies.

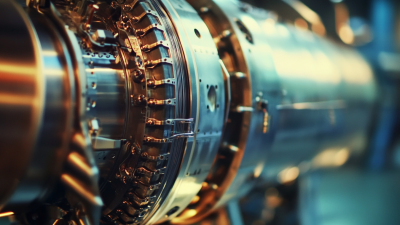

The aerospace machining industry is on the brink of a technological revolution, driven by emerging innovations that promise to transform manufacturing processes. According to a report by MarketsandMarkets, the global aerospace machining market is projected to grow at a CAGR of 5.3%, reaching $5.5 billion by 2025. This growth is fueled by advancements in precision machining technologies, including the adoption of computer numerical control (CNC) systems and additive manufacturing techniques. These technologies offer significant improvements in efficiency, accuracy, and material utilization, enabling manufacturers to produce complex components with reduced lead times.

In addition, the integration of Industry 4.0 concepts is reshaping aerospace machining. With the implementation of IoT devices and data analytics, manufacturers can optimize production processes, minimize downtime, and enhance quality control. A recent study by Deloitte emphasized that digital twin technology is becoming increasingly important in aerospace machining, allowing engineers to simulate and analyze machining processes before actual production. This not only reduces the risk of errors but also shortens the design cycle, ultimately contributing to a more agile and responsive manufacturing environment. As these technologies continue to evolve, they will play a crucial role in reshaping the future of aerospace machining, paving the way for innovations that enhance safety, performance, and sustainability in the skies.

As the aerospace industry continues to evolve, the importance of precision and quality in manufacturing processes becomes more pronounced.

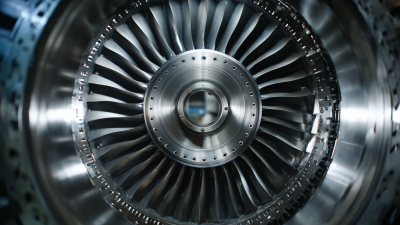

Advanced CNC machining is at the forefront of this transformation, offering capabilities that elevate traditional machining standards.

Utilizing computer-controlled tools, this innovative approach allows for unprecedented accuracy in cutting and shaping materials, which is critical for the stringent requirements of aerospace components.

Manufacturers can achieve tighter tolerances and intricate geometries, ensuring that each part meets the high-performance standards demanded by modern aircraft designs.

Moreover, the role of advanced CNC machining extends beyond mere accuracy. It introduces sophisticated techniques such as 5-axis machining, which enables the production of complex components in a single setup, thus reducing lead times and minimizing human error.

This streamlining of processes not only enhances efficiency but also improves the overall quality of the parts produced.

By integrating advanced CNC technology into their workflows, aerospace manufacturers can respond to the growing demands for lighter, stronger materials while optimizing their production capabilities to keep pace with innovation in aircraft design and engineering.

In recent years, additive manufacturing, commonly known as 3D printing, has emerged as a game-changer in the aerospace industry. According to a report by MarketsandMarkets, the global aerospace additive manufacturing market is projected to grow from $1.1 billion in 2020 to $3.5 billion by 2025, at a compound annual growth rate (CAGR) of 25.2%. This rapid advancement is driven by the need for lightweight, complex geometries that traditional manufacturing methods struggle to deliver, significantly enhancing the performance and efficiency of aerospace components.

The capability of additive manufacturing to produce parts on-demand reduces material waste and shortens production timelines. For instance, GE Aviation has successfully implemented 3D printing in the production of fuel nozzles, reducing the part count from 20 components to just one, while also cutting manufacturing time by 75%. Furthermore, a study from the National Center for Advanced Materials Performance highlights that parts made with additive techniques can weigh up to 30% less than their conventionally manufactured counterparts. This reduction in weight translates directly into improved fuel efficiency, a critical consideration in aerospace engineering. As innovators continue to refine these manufacturing processes, the impact of additive manufacturing will undoubtedly shape the future of aerospace component fabrication, setting new standards for efficiency, performance, and sustainability.

Sustainable practices in aerospace machining are gaining increasing importance as the industry seeks to reduce its environmental footprint. Innovations such as nitrogen cooling methods have shown significant potential in minimizing costs and energy consumption. Research indicates that implementing N2 cooling conditions can reduce total machining costs by up to 9.3% and lower energy use by 11.3%. This not only demonstrates a commitment to sustainability but also highlights the economic viability of greener practices that are essential in aerospace manufacturing.

Moreover, the rise of superalloys like Hastelloy X necessitates a focus on sustainable machining techniques, including cryogenic and Minimum Quantity Lubrication (MQL) methods. These techniques not only enhance machining efficiency but also contribute to lower emissions and waste generation. As the aerospace industry continues to explore sustainable aviation fuels and aircraft recycling processes, the incorporation of sustainable machining practices becomes a crucial component in the broader strategy towards achieving environmental sustainability. By prioritizing these innovations, the sector can pave the way for a more sustainable future while addressing the challenges of manufacturing ultra-performance components.

As the aerospace machining industry evolves, the demand for a skilled workforce capable of navigating emerging technologies becomes increasingly critical. According to a recent report by the Aerospace Industries Association, the aviation sector is expected to grow by over 4% annually, requiring an additional 240,000 skilled workers by 2035. This projected growth highlights the urgency for educational institutions and training programs to adapt their curricula to equip students with relevant skills in advanced machining techniques and digital technologies.

The future workforce in aerospace machining will need to be proficient in automation, robotics, and data analytics. The 2022 Workforce Development Report by the National Center for Aerospace Innovation and Research indicates that over 70% of companies report difficulties in finding qualified candidates with expertise in CAD/CAM software and additive manufacturing processes. Therefore, integrating these competencies into training programs is essential. Collaboration between industry leaders and educational bodies can pave the way for apprenticeships and hands-on training opportunities, ensuring that the next generation is well-prepared to meet the evolving demands of the aerospace sector.

| Skill Category | Specific Skills | Importance Level | Future Trends |

|---|---|---|---|

| Technical Skills | CNC Programming, CAD Software | High | Increased automation, advanced software |

| Quality Control | Inspection Techniques, Metrology | High | Data-driven quality analysis |

| Material Science | Composite Materials, Alloy Properties | Medium | Sustainability in material sourcing |

| Soft Skills | Problem-Solving, Teamwork | Medium | Collaboration in diverse teams |

| Technology Adaptation | 3D Printing, IoT Integration | High | Rapid technological advancements |