+86 180 0293 5268

+86 180 0293 5268

The aerospace industry is experiencing unprecedented growth, with the global aerospace machining market projected to reach approximately $20 billion by 2026, according to a recent report by MarketsandMarkets. As a vital component in manufacturing intricate aerospace parts, aerospace machining has become essential for global buyers seeking precision and efficiency in their supply chains. The continual advancements in technology, coupled with the increasing demand for lightweight and high-performance components, further accentuate the significance of strategic sourcing in this sector. Understanding the nuances of aerospace machining solutions not only enables purchasers to optimize costs but also ensures compliance with rigorous safety and quality standards mandated by aviation authorities. This ultimate guide aims to equip global buyers with the insights needed to navigate the complexities of sourcing aerospace machining solutions effectively, ultimately fostering stronger partnerships within this critical industry.

The aerospace industry is experiencing unprecedented growth, with the global aerospace machining market projected to reach approximately $20 billion by 2026, according to a recent report by MarketsandMarkets. As a vital component in manufacturing intricate aerospace parts, aerospace machining has become essential for global buyers seeking precision and efficiency in their supply chains. The continual advancements in technology, coupled with the increasing demand for lightweight and high-performance components, further accentuate the significance of strategic sourcing in this sector. Understanding the nuances of aerospace machining solutions not only enables purchasers to optimize costs but also ensures compliance with rigorous safety and quality standards mandated by aviation authorities. This ultimate guide aims to equip global buyers with the insights needed to navigate the complexities of sourcing aerospace machining solutions effectively, ultimately fostering stronger partnerships within this critical industry.

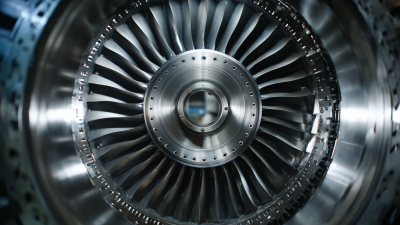

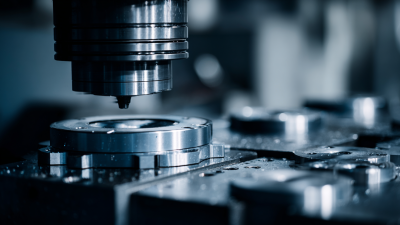

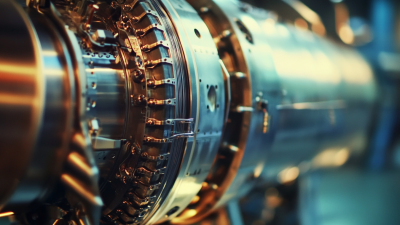

In the aerospace sector, machining processes play a critical role in manufacturing high-precision components that meet stringent industry standards. Key concepts such as CNC (Computer Numerical Control) machining, additive manufacturing, and materials like titanium and aluminum alloys are essential for producing lightweight yet durable parts. According to a 2022 report by Mordor Intelligence, the global aerospace machining market is projected to grow at a CAGR of 5.2% from 2023 to 2028, driven by increasing demand for fuel-efficient aircraft and the rise of electric propulsion systems.

Understanding essential terminology is vital for global buyers seeking reliable aerospace machining solutions. Terms like tolerance, surface finish, and machining cycles are fundamental in differentiating suppliers based on their capabilities. A study by MarketsandMarkets highlighted that the demand for high-precision, low-production volume parts has surged, emphasizing the importance of advanced machining techniques that cater to the unique requirements of aerospace applications. By grasping these key concepts and terms, buyers can make informed decisions in sourcing solutions that uphold safety and performance in the aerospace industry.

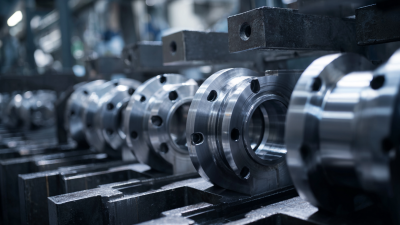

When it comes to sourcing aerospace machining solutions, the first step is identifying your specific needs. Every aerospace project is unique, requiring tailored solutions to meet regulatory standards and performance specifications. Begin by clearly outlining the technical requirements, materials, and tolerances necessary for your components. This clarity will help you communicate effectively with potential vendors and streamline the sourcing process.

**Tips:** Always consider engaging with manufacturers who have proven experience in aerospace machining. Investigate their certifications, as compliance with industry standards is crucial in ensuring the quality and reliability of the parts. Additionally, assess the vendor's ability to provide customization and flexibility in production schedules, which can be vital for meeting project deadlines.

Furthermore, don’t overlook the importance of collaboration early in the design phase. Involving your machining partner at this stage can lead to innovative solutions that enhance product functionality while reducing costs. Foster open communication about deadlines, budget constraints, and expected challenges to ensure both parties align on the project's goals. Careful planning in the beginning will pave the way for smoother execution and successful outcomes in your aerospace machining ventures.

| Application Area | Material Type | Machining Method | Tolerance Level | Lead Time |

|---|---|---|---|---|

| Jet Engine Components | Titanium Alloy | CNC Milling | 0.002 inches | 6 weeks |

| Airframe Structures | Aluminum Alloy | Laser Cutting | 0.005 inches | 4 weeks |

| Landing Gear Components | Steel Alloy | Precision Grinding | 0.001 inches | 8 weeks |

| Propeller Blades | Composite Material | 3D Printing | 0.01 inches | 5 weeks |

| Electronic Housings | Magnesium Alloy | CNC Turning | 0.003 inches | 3 weeks |

When evaluating suppliers for aerospace machining solutions, it’s crucial to consider several key factors that distinguish the best partners from the rest. First, assess the supplier’s experience and expertise in the aerospace sector, as specialized knowledge is essential for handling strict industry standards and complex machining requirements. Look for suppliers with a proven track record in delivering high-quality components that meet compliance regulations. Certifications such as AS9100 can provide assurance of their commitment to excellence and quality management systems.

Another important aspect is the supplier’s technological capabilities. In modern aerospace manufacturing, advanced machining technologies such as CNC (Computer Numerical Control) and additive manufacturing are critical for precision and efficiency. Ensure that potential partners invest in state-of-the-art equipment and continuously update their processes to stay competitive and meet evolving demands. Additionally, clear communication and strong project management practices are vital; suppliers should demonstrate their ability to collaborate effectively, provide timely updates, and adapt to changing specifications. By focusing on these criteria, global buyers can identify reliable aerospace machining partners that will support their operational goals and drive success in their projects.

Navigating the complex landscape of regulatory compliance in aerospace machining is fundamental for global buyers seeking to source reliable solutions. In a sector renowned for its stringent guidelines, such as those laid out by the FAA and EASA, understanding these regulations is crucial. According to a report by MarketsandMarkets, the global aerospace machining market is expected to grow from $XX billion in 2021 to $XX billion by 2026, highlighting the increasing necessity for compliance to ensure product quality and safety.

When sourcing aerospace machining services, it’s vital to prioritize suppliers who possess all necessary certifications, including AS9100 quality management standards. This certification is a testament to a manufacturer’s adherence to quality assurance processes specific to the aerospace industry. Additionally, establishing transparent communication with your suppliers can facilitate a better understanding of compliance requirements, as highlighted in a study by PwC, which states that 70% of companies viewed regulatory challenges as a primary obstacle in their operational effectiveness.

Tip: Always request documentation that proves a supplier’s compliance with relevant aerospace standards before entering into agreements. This not only mitigates risks but also fosters trust in the partnership. Another critical approach is to stay updated with changes in regulations through industry publications or professional networks, allowing you to adapt quickly to new compliance landscapes.

Cost management is becoming increasingly essential for global aerospace machining projects, especially amid the rising demand across the aerospace and defense sectors. A recent industry outlook indicates that global passenger traffic is projected to exceed 10 billion by 2025, creating significant pressure on manufacturers to optimize costs while meeting high production standards. Companies now face the dual challenge of balancing cost efficiency with supply chain resilience, prompting a reevaluation of sourcing strategies.

One of the key trends impacting cost management is the integration of advanced technologies such as artificial intelligence and machine learning, which enhance operational efficiencies in design and production processes. As the aerospace industry continues to operationalize these technologies, businesses can expect a decrease in manufacturing costs and an increase in overall productivity. Furthermore, recent investments in sustainable aerospace projects demonstrate a commitment to greener innovations while managing expenditures effectively. This dual focus not only advances environmental goals but also paves the way for long-term cost savings through improved material usage and energy efficiency.