+86 180 0293 5268

+86 180 0293 5268

In the ever-evolving world of aerospace manufacturing, efficiency and precision are paramount. As the industry continues to grow, the demand for advanced machining techniques is on the rise. Dr. Amelia Hart, a leading expert in Aerospace Machining, once stated, "Innovation in machining not only streamlines production but also enhances the overall quality and reliability of aerospace components." This highlights the critical need for aerospace engineers and manufacturers to continually adapt and refine their machining practices.

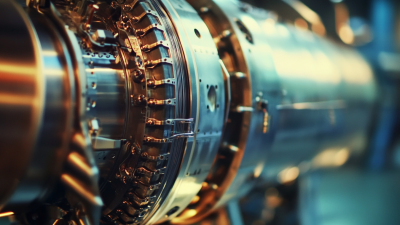

The integration of state-of-the-art technologies and optimized processes is essential for improving production efficiency in Aerospace Machining. Manufacturers are increasingly turning to sophisticated techniques such as five-axis machining, advanced material processing, and automation solutions. These innovative approaches not only reduce cycle times but also minimize waste, thereby contributing to a more sustainable manufacturing environment.

As we explore the seven best aerospace machining techniques, we will uncover how these methods can significantly enhance production efficiency. By investing in these advanced strategies, aerospace manufacturers can stay competitive in a dynamic market, ensuring the delivery of high-quality products that meet the rigorous demands of the industry.

Aerospace machining techniques play a pivotal role in the manufacturing process of aircraft components, significantly influencing production efficiency and product quality. The aerospace industry demands precision and reliability, making it essential to adopt innovative machining methods that can streamline workflows and enhance productivity. Modern techniques such as five-axis machining, computer numerical control (CNC) technology, and additive manufacturing are at the forefront of these advancements. These methods enable manufacturers to produce complex geometries with tighter tolerances, reduce material waste, and decrease lead times.

In addition to traditional machining processes, advanced techniques like electro-discharge machining (EDM) and laser machining are gaining traction due to their ability to handle tough materials and intricate designs. These methods facilitate the processing of high-strength alloys and composite materials commonly used in the aerospace sector. Furthermore, developments in automation and robotics are transforming the machining landscape, allowing for faster setup times and improved overall efficiency. By integrating these cutting-edge techniques, manufacturers can not only meet the stringent quality requirements of the aerospace industry but also achieve greater operational flexibility and cost-effectiveness.

In the aerospace industry, production efficiency is paramount for several reasons. First and foremost, the complexities involved in manufacturing aerospace components demand precision and speed. Any delay in the production line can result in significant project delays, leading to increased costs and potential loss of contracts. By focusing on production efficiency, aerospace manufacturers can minimize waste, streamline workflows, and enhance the overall quality of their products. This not only saves time and resources but also ensures that safety and regulatory standards are consistently met.

Moreover, with the global competition intensifying, maintaining high production efficiency allows companies to respond quickly to market demands and technological advancements. The adoption of advanced machining techniques can play a crucial role in this regard. Techniques such as precision machining and additive manufacturing can reduce material waste and lead times, thereby improving the agility of the production process. As a result, manufacturers become better equipped to innovate and adapt to changing industry standards, ultimately driving growth and sustainability in the aerospace sector. Enhancing production efficiency is not just an operational challenge; it is a strategic necessity that shapes the future of aerospace manufacturing.

| Technique | Description | Benefits | Applications |

|---|---|---|---|

| CNC Machining | Computer Numerical Control machining for high precision | High accuracy, repeatability, and reduced waste | Component manufacturing, prototypes |

| EDM (Electrical Discharge Machining) | Use of electrical discharges to machine hard materials | Can machine intricate shapes, minimal material stress | Mold making, forming tools |

| Additive Manufacturing | Layer-by-layer material addition to create parts | Reduces material waste, complex geometries | Lightweight components, rapid prototyping |

| Laser Cutting | Using lasers to cut through materials with high precision | High speed, accuracy, and clean cuts | Sheet metal fabrication, component cutting |

| Multi-Spindle Machining | Simultaneous machining of multiple parts | Increased production rates, lower unit costs | High volume production runs |

| Ultrasonic Machining | Machining using ultrasonic waves for difficult materials | Effective on hard, brittle materials, less tool wear | Ceramics, glass, composites |

| Hybrid Machining | Combining different machining processes for enhanced capabilities | Versatility, improved efficiency, reduced time | Complex aerospace components |

Precision machining is a critical element in aerospace applications, where the demands for accuracy and reliability are paramount. The key principles of precision machining include tight tolerances, surface finish quality, and adherence to strict specifications. Aerospace components often require extremely precise dimensions to ensure they function properly under the high-stress conditions of flight.

Utilizing advanced technologies such as CNC machining and additive manufacturing can greatly enhance the precision of component fabrication, allowing for more complex shapes and lightweight designs that contribute to overall efficiency.

Another essential principle is the selection of appropriate materials, which must withstand extreme environments, including high temperatures and varying pressures. Knowledge of material properties is crucial, as aerospace parts not only need strength but also must be manufactured in a way that minimizes weight without compromising performance.

Through techniques such as precision grinding, honing, and laser machining, manufacturers can achieve the desired characteristics that ensure safety and performance in aerospace applications. By focusing on these principles, the aerospace industry can continue to innovate, improving efficiency, reducing production times, and enhancing the reliability of its products.

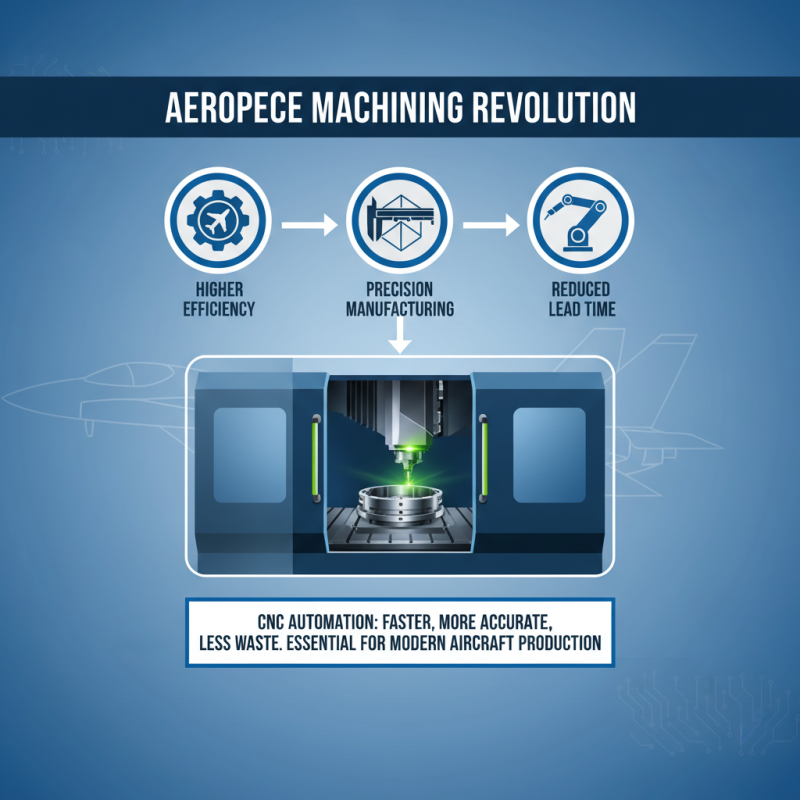

Innovative machining technologies have revolutionized the aerospace industry, enabling manufacturers to achieve higher production efficiency and precision. One such advancement is the integration of computer numerical control (CNC) machines, which allow for automated, precise cutting and shaping of materials. This technology minimizes human error and significantly reduces the time required for complex part fabrication, making it indispensable in modern aerospace manufacturing.

Another notable technique is additive manufacturing, or 3D printing, which facilitates the creation of intricate designs that were previously impossible or economically unfeasible. This method not only reduces material waste but also cuts down on production time by enabling rapid prototyping, leading to quicker project turnarounds. Furthermore, the ability to customize parts on demand enhances flexibility, allowing manufacturers to adjust to design changes swiftly without extensive retooling.

**Tips:** When implementing these innovative technologies, it is crucial to invest in skilled personnel who are proficient in operating advanced machinery. Regular training sessions can help your team stay updated on the latest advancements in aerospace machining. Additionally, maintaining an open line of communication between production and design teams can improve efficiency by allowing for quicker feedback and adjustments during the manufacturing process. Leveraging data analytics to monitor production outcomes can also yield insights that drive continuous improvement.

The aerospace industry demands precision and efficiency, making the choice of machining techniques critical for production optimization. A comparative analysis of traditional versus advanced machining techniques reveals significant disparities in productivity and cost-effectiveness. Traditional methods, such as conventional milling and turning, have long been the backbone of aerospace manufacturing. However, they often fall short in meeting the increasingly stringent tolerances required in modern aerospace components, leading to longer lead times and higher production costs. According to a report by the Aerospace Industries Association, efficiency improvements are necessary to keep up with the projected growth in air travel, with a demand for over 39,000 new aircraft forecasted over the next two decades.

In contrast, advanced machining techniques such as additive manufacturing, CNC machining, and electrical discharge machining (EDM) are transforming the aerospace landscape. These methods can significantly reduce waste and lead time while allowing for complex geometries that traditional techniques might be unable to achieve. A study by the National Institute of Standards and Technology highlighted that companies implementing advanced machining techniques report productivity increases of up to 30% and reductions in material waste by as much as 50%. As manufacturers strive to meet stricter performance standards and sustainability goals, the shift toward advanced machining techniques becomes not just beneficial but imperative for maintaining competitiveness in the aerospace sector.