+86 180 0293 5268

+86 180 0293 5268

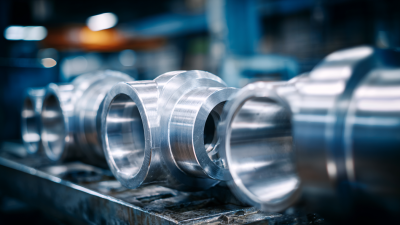

When it comes to selecting materials for your projects, the choice of casting can profoundly influence both performance and longevity. Among the various options available in the market, Stainless Steel Castings stand out as a premier choice for manufacturers and designers alike. Renowned for their remarkable durability, resistance to corrosion, and overall versatility, stainless steel castings offer several advantages that can enhance the efficiency and effectiveness of any project. In this article, we will explore the five essential benefits of choosing stainless steel castings, delving into how these attributes can lead to superior product outcomes. Whether you are involved in the aerospace, automotive, or any other industry requiring reliable components, understanding the significance of stainless steel castings will guide you in making informed decisions that align with your project goals.

Stainless steel castings are renowned for their exceptional corrosion resistance, making them an ideal choice for various industrial applications. This inherent property is primarily due to the presence of chromium, which forms a passive oxide layer on the surface of the steel. This layer acts as a barrier against moisture and corrosive elements, ensuring that the material remains intact even in harsh environments. Industries such as marine, chemical processing, and food manufacturing benefit immensely from this feature, as it helps prevent costly equipment failures and maintains product integrity.

In addition to prolonging the lifespan of components, the corrosion resistance of stainless steel castings contributes to lower maintenance costs. Unlike other materials that may require frequent replacements or repairs due to rusting or degradation, stainless steel offers a reliable solution that reduces downtime. Furthermore, its durability allows for the production of intricate shapes and designs, which can enhance the functionality and appearance of products. Overall, the advantages of corrosion resistance in stainless steel castings make them a smart investment for long-term project success.

Stainless steel castings are notably superior in terms of durability and strength when compared to other metals. According to a recent industry report from the World Stainless Steel Forum, stainless steel's enhanced corrosion resistance and tensile strength—up to 250 MPa—make it a preferred choice in applications that demand long-lasting materials. This inherent durability allows structures and components to withstand harsh environments without succumbing to wear and tear, significantly reducing maintenance costs over time.

Moreover, advancements in steel technology highlight its status as a precious metal in various applications. In contrast to lightweight alternatives like carbon and titanium, stainless steel benefits from a robust design that provides both strength and reliability. A study by the International Journal of Engineering Research indicates that stainless steel can outperform titanium in certain scenarios, primarily due to its superior fatigue strength and lower manufacturing costs. This aspect makes stainless steel not only a resilient option for commercial and industrial use but also an ideal choice for the evolving landscape of modern engineering projects.

When it comes to project planning, cost-effectiveness is often a top priority for businesses. Stainless steel castings present a prime solution that ensures long-term savings. Although the initial investment may seem higher compared to other materials, the durability and resistance to corrosion offered by stainless steel significantly reduce maintenance costs over time. This means fewer replacements and repairs, which can lead to substantial financial savings in the long run.

Moreover, stainless steel castings can enhance operational efficiency due to their strength and reliability. This reliability minimizes downtime caused by equipment failure, translating into increased productivity. Additionally, the remarkable longevity of stainless steel castings means fewer interruptions to production schedules, further solidifying their cost-effective nature. By choosing stainless steel castings, companies are not only investing in high-quality materials but also setting the foundation for sustained financial benefits throughout the lifecycle of their projects.

Stainless steel castings are known for their exceptional versatility, making them the ideal choice for a wide range of applications across various industries. From automotive components to food processing equipment, stainless steel castings excel in environments demanding durability, corrosion resistance, and hygiene. With the rising demand in the construction and real estate sectors, particularly in India, the stainless steel market is set to grow robustly by an estimated 15% CAGR over the next seven years. This growth is driven by manufacturers shifting towards high-performance materials capable of meeting stringent environmental and safety standards.

When considering stainless steel castings for your projects, here are a couple of tips: First, assess the specific requirements of your application, such as load-bearing capacity and resistance to harsh environments, to ensure optimal material selection. Second, take advantage of advanced manufacturing technologies that enhance the properties of stainless steel, such as lightweight composite structures, allowing for improvements in design flexibility and efficiency.

In the competitive landscape, stainless steel castings stand out by offering not only functional benefits but also , making them suitable for high-end consumer products. Companies utilizing these castings are likely to experience enhanced product performance, positioning themselves favorably within their respective markets.

When it comes to design, aesthetic appeal is paramount, and stainless steel castings offer a striking visual advantage. The sleek, reflective surface of stainless steel adds a modern touch to any project, making it a favorite choice among architects and designers. Whether used in furniture, fixtures, or architectural elements, the brilliance of stainless steel enhances the overall look, giving spaces a sophisticated and contemporary feel.

Tips: When incorporating stainless steel into your designs, consider the surrounding materials to create a harmonious balance. Pairing it with warm woods can soften the industrial look, while the combination with glass can accentuate modernity.

Moreover, the versatility of stainless steel castings allows for intricate designs without sacrificing strength or durability. The ability to create detailed shapes and forms makes it a perfect material for custom projects. As stainless steel is resistant to tarnishing, it maintains its aesthetic appeal over time, ensuring your designs remain stunning year after year.

Tips: Use various finishes, like brushed or polished, to achieve different visual effects. Experimenting with textures can also create depth, enhancing the timeless elegance of your stainless steel elements.