+86 180 0293 5268

+86 180 0293 5268

CNC machined parts have revolutionized the manufacturing industry. Their precision and efficiency are unparalleled, leading to enhanced productivity. According to a report by Industry Week, 80% of manufacturers cited increased efficiency from CNC machining. These parts are often more accurate than those made by traditional methods.

The benefits extend beyond precision. CNC machined parts can be produced in various materials, enabling versatility. A survey by Research and Markets indicated that the global CNC market is projected to reach $100 billion by 2025. However, the high initial cost of CNC machines can be a barrier for smaller companies.

While CNC machined parts offer significant advantages, there are challenges. Not all designs are optimized for machining, and sometimes materials can limit performance. Finding a balance between cost and quality is essential for manufacturers. Addressing these issues ensures that CNC machining continues to evolve and meet industry demands.

CNC machining offers exceptional precision and accuracy, key benefits for manufacturing industries. Reports indicate that precision machining can reduce tolerances to as little as ±0.01 mm. Such accuracy is vital in sectors like aerospace and automotive, where even minor errors can lead to significant failures. High precision ensures that parts fit together seamlessly, enhancing product quality and reliability.

The ability to produce intricate shapes consistently is another advantage. CNC machines can operate continuously with minimal downtime, which boosts productivity. Companies report increased efficiency by up to 30% when utilizing CNC technology. However, achieving this precision requires careful programming and operator training. Operators must understand both the machines and the materials used.

Tips: Always confirm machine calibration before starting a new batch. Regular maintenance can prevent common machining errors. Investing in skilled operators pays off in the long run.

Even with advanced technology, perfection is not guaranteed. Calibration errors can occur, and material inconsistencies can impact results. Continuous monitoring and adjustments are essential to maintain high standards in production. Emphasizing accuracy enhances not just the final product but the entire manufacturing process. The pursuit of perfection in CNC machining is ongoing and requires commitment.

CNC machined parts are revolutionizing manufacturing by providing exceptional consistency and repeatability. According to industry reports, up to 98% accuracy is achievable with CNC machining. This means parts can be produced with minimal variation, which is crucial for industries like aerospace and automotive. These sectors often require tight tolerances. A single mistake can lead to costly failures.

Moreover, CNC machines do not experience fatigue. Unlike human operators, they consistently perform at the same level throughout production runs. This translates to fewer defects and rejects. A manufacturing study showed that companies utilizing CNC machining saw a 30% reduction in rework and scrap rates. Yet, reliance on CNC technology may lead companies to overlook the importance of operator skills. Machines require skilled technicians for optimal programming and maintenance.

It's worth noting that while CNC machining offers high precision, the initial setup can be complex. This complexity may result in higher upfront costs and longer lead times when starting new projects. Additionally, over-reliance on automated processes can lead to complacency among staff. A balanced approach is essential for sustained success. By combining technology with human insight, manufacturers can maximize efficiency and output quality.

This bar chart illustrates the key benefits of CNC machined parts in manufacturing processes, highlighting their advantages in consistency, repeatability, precision, efficiency, and material utilization.

CNC machined parts are a cornerstone of modern manufacturing. They offer significant cost-effectiveness, which is crucial for companies looking to optimize resources. A recent industry report highlighted that CNC machining can reduce production costs by up to 30%. This efficiency comes from the high precision and repeatability of CNC processes.

Moreover, CNC machining allows for minimal material waste. A study found that traditional machining processes can waste around 20% of the material. In contrast, CNC methods often achieve waste rates below 5%. This reduction helps companies save money and resources.

However, it is important to acknowledge that investing in CNC technology requires a substantial upfront cost. The initial setup of CNC machines can be daunting for small businesses. They might struggle with the return on investment, especially in the early stages. Balancing these costs with expected gains is a challenge worth considering.

| Benefit | Description | Cost Implication |

|---|---|---|

| Precision | High accuracy and tight tolerances for complex shapes. | Reduces waste and lowers rework costs. |

| Speed | Faster production times due to automation. | Increases throughput and decreases labor costs. |

| Flexibility | Ability to produce a variety of parts without changeover time. | Cost savings on setup and tooling changes. |

| Material Efficiency | Minimizes material waste compared to traditional methods. | Lowers raw material costs significantly. |

| Repeatability | Consistent production of identical parts. | Ensures reliability and decreases costs associated with variability. |

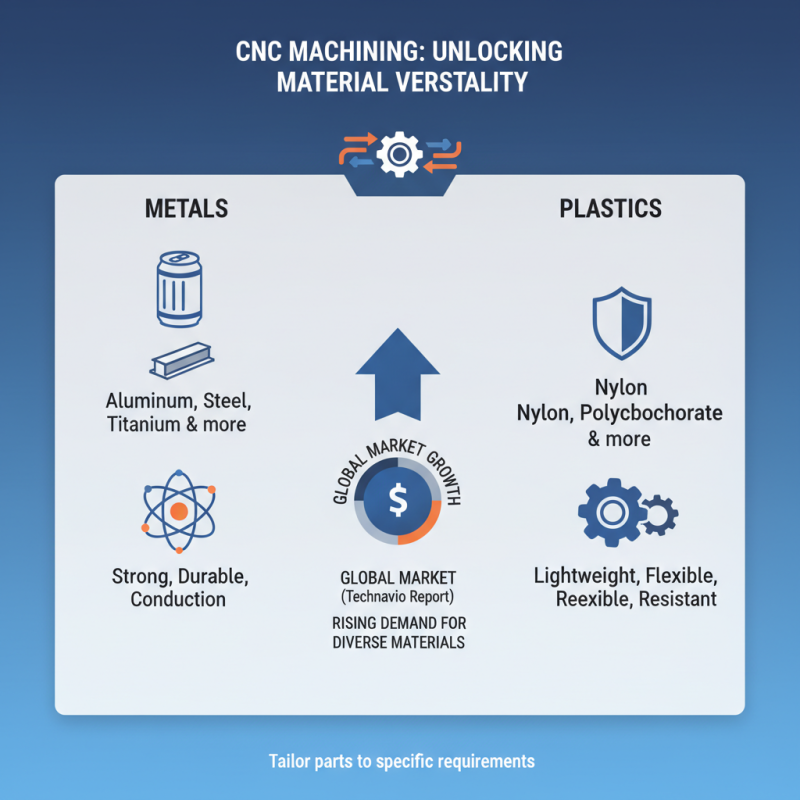

CNC machining offers remarkable versatility in material options, providing manufacturers with a wide range of choices. Metals like aluminum, steel, and titanium are common, but plastics such as nylon and polycarbonate are also popular. According to a report by Technavio, the global CNC machining market is expected to grow significantly, indicating a rising demand for diverse materials. This versatility allows businesses to tailor parts to specific requirements.

Manufacturers often face challenges when selecting materials. Not all materials work well in CNC machining, and some may require unique cutting tools or techniques. Studies show that selecting the wrong material can lead to production delays or increased costs. Additionally, the mechanical properties of materials can affect the final product. Fragile materials may break during machining, while tougher materials can cause tool wear.

Despite these hurdles, the ability to choose from various materials provides great flexibility. For instance, aluminum is lightweight yet strong, ideal for aerospace parts. In contrast, a plastic like ABS is cost-effective for prototyping. Companies must weigh the pros and cons of each material carefully. Understanding the limitations of each option can lead to informed decisions, ensuring efficiency in the production process.

CNC machined parts are revolutionizing manufacturing. One significant advantage is the reduction in lead times. Traditional manufacturing methods often involve lengthy setup processes. In contrast, CNC machining uses computer control to streamline production. This technology allows for rapid adjustments and minimizes downtime.

Increased production efficiency is another key benefit. CNC machines can operate continuously, resulting in high output rates. They produce consistent quality, which reduces the need for rework and ensures better resource allocation. However, it's essential to balance speed with precision. Some operations may focus too much on rapid production, sacrificing quality and accuracy.

Furthermore, the setup cost for CNC machining can be high. This may deter some manufacturers from making the switch. Investing in the latest technology requires careful planning and consideration. The long-term benefits often justify the initial expense, but businesses must ensure that they are ready for this transition. The challenge is in finding the right balance between efficiency and consistent quality.