+86 180 0293 5268

+86 180 0293 5268

In the ever-evolving landscape of manufacturing, "Precision Metal Machining" has emerged as a cornerstone for businesses striving for excellence and efficiency. As we delve into the top benefits of this advanced machining process in 2023, we must consider the insights of industry expert Dr. Alan Thompson, a renowned figure in precision engineering. Dr. Thompson once stated, "Precision Metal Machining not only enhances product quality but also significantly reduces costs through optimized processes." This assertion underscores the critical role that precision machining plays in competitive manufacturing environments.

The benefits of adopting precision machining techniques are multifaceted, ranging from improved product accuracy to the ability to produce complex geometries that traditional methods may struggle to achieve. Companies that leverage these advanced techniques not only enhance their production capabilities but also position themselves at the forefront of innovation. As we explore the multitude of advantages this technology offers, it becomes clear that embracing Precision Metal Machining is not just a choice for 2023, but a strategic decision that can define a business's trajectory in the years to come.

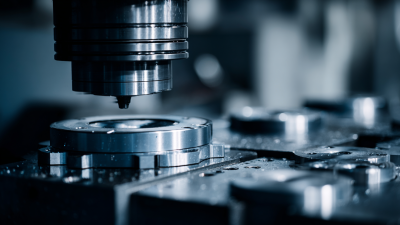

Precision metal machining plays a vital role in enhancing product quality across various industries. By utilizing advanced machinery and techniques, businesses can achieve intricate designs and tight tolerances that ensure superior performance and durability in their products. This meticulous approach not only elevates the aesthetic appeal of components but also minimizes the risk of defects, leading to higher customer satisfaction and loyalty.

Tip: To fully leverage the benefits of precision machining, invest in training for your staff. Skilled operators can maximize the capabilities of machining equipment, resulting in higher efficiency and reduced waste.

Furthermore, precision metal machining allows for quicker prototyping and manufacturing processes. This adaptability enables companies to respond rapidly to market demands and implement design changes with ease. As a result, businesses can maintain a competitive edge while consistently delivering high-quality products that meet or exceed industry standards.

Tip: Consider collaborating with experienced machining partners who utilize the latest technology. This partnership can streamline your production line and ensure that your products are manufactured to the highest quality levels.

Precision metal machining offers significant cost efficiency for businesses by minimizing waste and errors in production processes. This advanced machining technique utilizes computer-controlled tools to create highly accurate components, which reduces the likelihood of material wastage. By ensuring that each piece is crafted with precision, companies can maintain tighter tolerances and eliminate the costs associated with rework and scrap. This approach not only enhances product quality but also optimizes resource usage, ultimately leading to lower operational costs.

To further improve cost efficiency, companies should invest in regular maintenance of their machining equipment. A well-maintained machine will operate more efficiently and produce fewer defects. Additionally, training staff in best practices for precision machining can significantly reduce errors. It's advisable to implement a continuous improvement program that encourages feedback from employees about the machining processes. This will help identify potential inefficiencies and foster an environment of innovation.

Leveraging software solutions for machining can also enhance productivity and reduce waste. By utilizing simulation and modeling tools, businesses can forecast potential mistakes and adjust their processes before production even begins. Integrating these technologies not only saves time and materials but can also lead to a faster return on investment. Embracing precision metal machining is a strategic move that pays dividends, promoting both cost savings and enhanced operational performance.

Precision metal machining has emerged as a game-changer in the manufacturing sector, particularly in boosting production speed. With advancements in technology, precision machining processes have become more efficient, allowing businesses to reduce lead times significantly. By employing high-precision tools and automated machinery, companies can achieve faster turnaround times without compromising on quality. This efficiency ensures that production schedules are met consistently, enhancing overall productivity.

The time-saving advantages of precision machining extend beyond mere speed; they also contribute to minimizing material waste and optimizing resource utilization. By accurately cutting and shaping metals to exact specifications, manufacturers can reduce rework and scrap rates. This not only accelerates the production cycle but also lowers operational costs, providing businesses with a competitive edge in an increasingly fast-paced market. As companies strive to meet the high demands of their customers, the integration of precision machining into their production processes becomes essential for success in 2023 and beyond.

| Benefit | Description | Impact on Production Speed | Estimated Time Savings (%) |

|---|---|---|---|

| Increased Accuracy | Precision machining allows for tighter tolerances, reducing errors and rework. | Significantly boosts accuracy of parts. | 20% |

| Reduced Material Waste | Optimizes material usage through precise cuts. | Lowering overall costs and increasing efficiency. | 15% |

| Automated Processes | Integration of CNC machines reduces manual interventions. | Speeds up production cycles. | 25% |

| Better Design Flexibility | Allows for complex geometries that traditional machining can't achieve. | Support for innovative product designs. | 10% |

| Shorter Lead Times | Faster production from start to finish. | Quick response to market demands. | 30% |

| Enhanced Surface Finish | Precision machining provides superior finishes. | Minimizes need for post-production finishing. | 18% |

| Improved Product Durability | Higher quality parts contribute to better overall product lifespan. | Leads to fewer returns and repairs. | 12% |

| Scalability | Facilitates easy scaling of production as demand grows. | Ensures readiness for increased orders. | 22% |

| Consistent Quality | Maintains high-quality standards across all produced parts. | Fosters customer trust and brand reputation. | 17% |

| Cost-effectiveness | Reduces labor costs and enhances profit margins over time. | Overall improvement in ROI. | 20% |

Precision metal machining offers unparalleled customization capabilities that can significantly enhance a business's operational efficiency and product quality. In 2023, companies are increasingly leaning towards tailored solutions that meet their specific requirements. This adaptability allows businesses to create components with exact specifications, ensuring that parts fit seamlessly into existing systems or machinery. By employing advanced machining technologies, organizations can modify designs rapidly, enabling them to address unique challenges and customer demands effectively.

Moreover, the ability to customize parts can lead to reduced waste and improved resource utilization. Businesses no longer have to rely on generic components that may not fully meet their needs, which often results in excess inventory and higher costs. Instead, with precision metal machining, they can produce just what they need, when they need it. This proactive approach not only enhances production timelines but also fosters innovation, as companies can experiment with new designs or materials without the risk associated with larger, traditional manufacturing processes. Overall, the customization capabilities provided by precision metal machining position businesses to be more agile and responsive in a competitive market.

This chart illustrates the top 10 benefits of precision metal machining for businesses in 2023, demonstrating the importance of each aspect on a scale of 1 to 10. Customization and quality are the highest priorities for businesses looking to enhance their operations through precision machining.

The landscape of precision metal machining is set to undergo significant transformations by 2025, influenced by advancements in technology and material science. One of the most notable innovations on the horizon is the integration of artificial intelligence in machining processes. AI can optimize production schedules, predict maintenance needs, and enhance quality control, thereby increasing efficiency and reducing downtime. Companies willing to adopt AI-driven solutions will likely see a competitive edge in the fast-evolving market.

Another promising trend is the rise of additive manufacturing techniques, commonly known as 3D printing. These methods allow for the creation of complex geometries that were previously impossible with traditional machining. This shift not only reduces material waste but also opens avenues for rapid prototyping. Businesses should consider investing in training for their teams to familiarize themselves with these technologies, ensuring they remain at the forefront of innovation.

Tips: To stay ahead, regularly attend industry workshops and webinars focusing on new technologies. Collaborating with tech start-ups that specialize in precision machining technology can also provide invaluable insights. Additionally, keeping an open line of communication with suppliers may lead to early access to emerging tools and materials that enhance your machining capabilities.