+86 180 0293 5268

+86 180 0293 5268

In the realm of manufacturing, the investment casting aluminum technique stands out for its precision and versatility. Industry expert Dr. Emily Carter, a leading authority in metal casting processes, emphasizes the importance of mastering this technique, stating, "The future of lightweight structures lies in the refined art of investment casting aluminum, where every detail counts." With the rising demand for high-performance components across various sectors, understanding the best practices in investment casting aluminum is essential for engineers and manufacturers alike.

This article delves into the ten best investment casting aluminum techniques that promise superior results. Each method outlined here not only enhances the quality of the finished product but also streamlines the overall production process. From optimizing mold designs to choosing the right alloy, we aim to equip professionals with the knowledge needed to excel in an ever-evolving industry. As Dr. Carter suggests, exploring innovative techniques in investment casting aluminum can lead to significant advancements in product development and manufacturing efficiency.

When it comes to investment casting aluminum, the selection of alloys is paramount for achieving optimal performance. Advanced alloys such as 356 aluminum are often chosen for their excellent casting characteristics and superior strength-to-weight ratio. These alloys not only enhance fluidity during pouring but also ensure robust mechanical properties in the finished part, making them ideal for demanding applications in aerospace and automotive industries.

Tips for selecting the right alloy include evaluating the specific application requirements, including strength, corrosion resistance, and thermal conductivity. Additionally, consider the casting process—certain alloys perform better in lower temperature ranges or in complex geometries. Don’t hesitate to consult with materials engineers for insight into how different alloy compositions can impact your project’s success.

Furthermore, it's essential to address the thermal treatment processes post-casting. Solutions such as aging can significantly improve the material's hardness and overall performance. Keeping a close eye on the cooling rates during solidification can also lead to finer microstructures, enhancing the mechanical properties of the final cast. Always prioritize testing and validation to ensure that the selected alloy meets all performance criteria before moving forward with production.

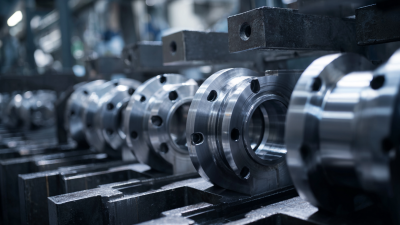

Innovative mold design techniques are essential in enhancing casting precision in investment casting aluminum. By utilizing advanced computer-aided design (CAD) software, manufacturers can create intricate mold geometries that improve the overall fit and finish of the final product. This technology allows for precise control over the mold's dimensions and surface textures, reducing imperfections and leading to a higher-quality casting.

Moreover, the integration of 3D printing in mold production offers a transformative approach to investment casting. Rapid prototyping enables the creation of complex and highly detailed molds that traditional methods might struggle to achieve. This not only speeds up the production process but also allows for greater experimentation with mold designs, ultimately leading to superior casting results. By implementing these innovative mold design techniques, manufacturers can significantly enhance the efficiency and accuracy of their aluminum investment casting operations.

This chart illustrates the efficiency of various investment casting aluminum techniques based on their casting precision and compatibility with innovative mold designs. The techniques are ranked according to their effectiveness in achieving superior casting results.

Investment casting is evolving with an increasing focus on sustainability, especially in aluminum production. By implementing sustainable practices, manufacturers can significantly reduce waste and enhance energy efficiency throughout the casting process. Techniques such as the use of recyclable materials, optimizing energy consumption, and minimizing emissions not only meet regulatory standards but also appeal to environmentally conscious consumers. Companies are exploring advanced technologies that enhance melting efficiency, leading to a reduction in overall energy usage during the aluminum casting cycle.

Additionally, adopting sustainable practices in aluminum investment casting can further improve the supply chain. By collaborating with suppliers who prioritize green manufacturing processes, businesses can ensure that their raw materials are sourced responsibly. Innovations like using water-based coatings instead of solvent-based ones help mitigate environmental impacts and improve worker safety. Such practices not only bolster a company’s reputation as a responsible manufacturer but also contribute to long-term cost savings, showcasing that sustainability and profitability can go hand in hand in the investment casting industry.

In today's rapidly evolving manufacturing landscape, the integration of smart technology into investment casting is transforming quality control processes. The implementation of real-time monitoring systems is crucial for ensuring the integrity and precision of aluminum castings. According to a report by MarketsandMarkets, the global smart manufacturing market is projected to grow from $214 billion in 2020 to $384 billion by 2025, highlighting a significant trend toward enhanced operational efficiency through advanced technologies.

In today's rapidly evolving manufacturing landscape, the integration of smart technology into investment casting is transforming quality control processes. The implementation of real-time monitoring systems is crucial for ensuring the integrity and precision of aluminum castings. According to a report by MarketsandMarkets, the global smart manufacturing market is projected to grow from $214 billion in 2020 to $384 billion by 2025, highlighting a significant trend toward enhanced operational efficiency through advanced technologies.

Investors and manufacturers are increasingly utilizing data analytics, Internet of Things (IoT), and machine learning to streamline casting operations. These tools enable real-time quality assessment, reducing scrap rates and improving yield. A study by McKinsey & Company suggests that companies leveraging IoT in manufacturing can achieve productivity gains of up to 20%. Such advancements allow for immediate corrective actions during the casting process, thereby minimizing defects and ensuring a superior quality end product.

Tip: To optimize your investment casting process, consider integrating temperature and pressure sensors that provide instant feedback during casting. This will not only enhance quality control but also lead to long-term savings and efficiency improvements. Additionally, establishing a digital dashboard for monitoring key performance indicators (KPIs) can help track progress and facilitate real-time decision-making.

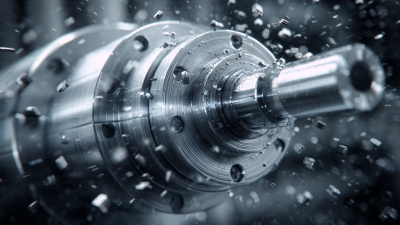

Advanced heat treatment processes play a crucial role in maximizing production efficiency in investment casting aluminum. By employing techniques such as annealing and aging, manufacturers can significantly enhance the material properties of aluminum castings. These processes not only improve strength and ductility but also optimize the overall performance of the end products. As the industry continues to evolve, staying abreast of these methods is essential for maintaining competitive advantage and ensuring superior results.

Tips for effective heat treatment include maintaining precise temperature control during the process. This ensures uniformity in the casting, preventing potential defects. Additionally, consider implementing a systematic approach to cooling methods. Rapid cooling can promote hardening, while controlled cooling can improve toughness. By regularly monitoring these parameters, manufacturers can fine-tune their processes for optimal outcomes, reducing waste and improving product quality.

Investing in automatic heat treatment systems can also streamline operations. These systems offer better control and consistency compared to manual methods. By automating temperature adjustments and time schedules, companies can reduce labor costs and minimize human error. As a result, the combination of advanced heat treatment techniques and automation can elevate the efficiency and reliability of investment casting aluminum processes.