+86 180 0293 5268

+86 180 0293 5268

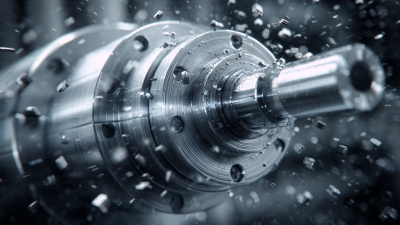

In the rapidly evolving landscape of manufacturing, the production of CNC machined parts presents a set of unique challenges that can significantly impact product quality and operational efficiency. According to a recent report by Grand View Research, the global CNC machining market is expected to reach $100 billion by 2025, driven by increased demand for precision components across various industries such as aerospace, automotive, and medical devices. However, with this growth comes a heightened complexity in ensuring quality assurance throughout the production process. Factors such as equipment calibration, tool wear, and material selection can greatly influence the final product's accuracy and finish. This ultimate guide aims to illuminate the intricacies involved in CNC machined part production and the importance of implementing robust quality control measures to mitigate potential issues and optimize manufacturing outcomes.

In the realm of CNC machined part production, understanding the challenges and statistical insights is crucial for maintaining quality and efficiency. Recent research highlights that defects in manufacturing processes, such as inaccuracies in dimensions due to machine tool failures or inappropriate cutting conditions, significantly impact production quality. A systematic review indicates that as industries become increasingly automated, the variability introduced by human operators is reduced, yet the complexity of machinery can give rise to new uncertainties. For instance, the challenges posed by additive manufacturing technologies, particularly in methodologies like Directed Energy Deposition (DED), underscore the need for stringent quality assurance protocols. The DED process often grapples with the physical characteristics of the materials used, leading to defects that require careful monitoring and control (Source: DED Additive Manufacturing: Physical Characteristics, Defects, Challenges and Applications).

Moreover, the unpredictability of the metal additive manufacturing market further complicates the landscape. According to a study by AMPPOWER, the intricate nature of this sector makes it challenging to forecast trends accurately. This unpredictability is compounded by varying production methods and materials, which often result in different defect rates and quality assurance challenges. As a result, manufacturers must invest in advanced analytics and process optimization strategies to keep pace with evolving market demands and to assure the reliability of their machined parts (Source: Predicting the Metal Additive Manufacturing Market). The need for continuous innovation and revision of best practices in CNC machining remains a pivotal focus for industry professionals aiming to enhance production quality while mitigating risks.

| Challenge | Impact on Production (%) | Common Causes | Quality Assurance Methods |

|---|---|---|---|

| Material Variability | 25 | Supplier inconsistencies, batching issues | Incoming Material Inspection |

| Tool Wear and Tear | 20 | Lack of maintenance, incorrect tool selection | Regular Tool Inspections |

| Process Variation | 30 | Operator skill differences, machine settings | Statistical Process Control (SPC) |

| Dimensional Accuracy | 15 | Improper calibration, thermal expansion | CMM (Coordinate Measuring Machine) Inspection |

| Surface Finish | 10 | Inadequate machining parameters, tooling issues | Visual Inspection and Surface Profiling |

Material variability plays a crucial role in the quality assurance of CNC machined parts. According to a report by the National Institute of Standards and Technology (NIST), variations in material properties can lead to inconsistencies in machining outcomes, affecting factors such as tolerance levels and surface finish. For instance, differences in hardness, grain structure, and composition can significantly alter how a material responds during the machining process, resulting in increased rejection rates and costly rework. In fact, a study from the American Machinist reported that approximately 30% of all machining issues can be traced back to material quality problems.

Material variability plays a crucial role in the quality assurance of CNC machined parts. According to a report by the National Institute of Standards and Technology (NIST), variations in material properties can lead to inconsistencies in machining outcomes, affecting factors such as tolerance levels and surface finish. For instance, differences in hardness, grain structure, and composition can significantly alter how a material responds during the machining process, resulting in increased rejection rates and costly rework. In fact, a study from the American Machinist reported that approximately 30% of all machining issues can be traced back to material quality problems.

Furthermore, the unpredictable nature of raw materials can complicate the quality assurance process even further. The International Organization for Standardization (ISO) emphasizes that implementing rigorous quality checks is essential to mitigate the effects of material variability. Advanced techniques, such as real-time monitoring of machining processes and employing statistical process control (SPC), can aid manufacturers in understanding and managing these challenges. By closely analyzing the material's properties and their implications on the machining process, manufacturers can improve their quality assurance protocols and outcomes, ultimately leading to enhanced product reliability and customer satisfaction.

In modern CNC machined part production, automation plays a crucial role in minimizing numerous challenges associated with traditional manufacturing processes. By integrating advanced machinery and robotics, manufacturers can enhance precision, reduce errors, and optimize production times. Automation streamlines workflows by performing repetitive tasks with consistent accuracy, thereby alleviating the burden on human operators and enabling them to focus on more complex problem-solving activities.

**Tip:** When considering automation, start with a thorough analysis of your current processes. Identify bottlenecks and areas where automation can provide the greatest impact. Implementing incremental changes can help in adapting your workforce to new technologies gradually.

Furthermore, the implementation of automated quality assurance systems ensures that parts meet stringent specifications. These systems utilize sensors and imaging technology to detect imperfections, allowing for real-time adjustments in the production line. This proactive approach not only reduces waste but also enhances overall product reliability.

**Tip:** Invest in training your team to understand and operate automated systems effectively. A well-informed workforce can maximize the benefits of automation and help troubleshoot potential issues before they escalate.

Quality assurance in CNC machining has become a critical aspect of the production process, transitioning from a luxury to a necessity in the industry. According to a report from the International Organization for Standardization (ISO), implementing rigorous quality assurance standards can reduce defects by up to 50%, ultimately saving manufacturers time and resources. As competition intensifies and customer demands evolve, adherence to quality standards is no longer optional but essential for sustaining business growth and customer satisfaction.

When integrating quality assurance protocols, manufacturers should consider the use of advanced inspection technologies such as Coordinate Measuring Machines (CMM) and laser scanners. These tools not only provide accurate measurements but also enhance efficiency by allowing for real-time adjustments during the manufacturing process. Additionally, implementing a robust training program for staff can significantly improve product quality. A study by the National Institute of Standards and Technology (NIST) indicates that organizations investing in employee training see a 20% increase in productivity and quality performance.

To maintain high-quality standards, it is advisable to conduct regular audits and reviews of the production process. Consistent evaluations help identify potential areas of improvement and ensure compliance with ISO standards. Furthermore, embracing a culture of continuous improvement will equip organizations to adapt to evolving industry standards and customer expectations effectively.

The future of CNC machining is driven by the increasing demand for precision and efficiency across various industries. According to recent projections, the market for CNC machinery is expected to reach a significant scale by 2032, highlighting the growing trend towards digital manufacturing technologies. These advancements not only enhance productivity but also allow manufacturers to respond quickly to market demands. With the implementation of eco-friendly solutions and automated processes, companies can transition from conventional operations to more sophisticated, environmentally sustainable methods.

Furthermore, the chip removal machine market is anticipated to grow from an estimated $1.5 billion in 2024 to $2.8 billion by 2033, reflecting a robust annual growth rate of 7.5%. This surge underscores the industry's shift towards high-precision tasks and the utilization of advanced machinery to meet stringent production standards. As CNC machining technology evolves, it becomes vital for manufacturers to adopt these innovations to maintain competitiveness and meet the escalating expectations for quality assurance in part production. This adaptation will not only fulfill current market needs but also pave the way for future advancements in manufacturing capabilities.