+86 180 0293 5268

+86 180 0293 5268

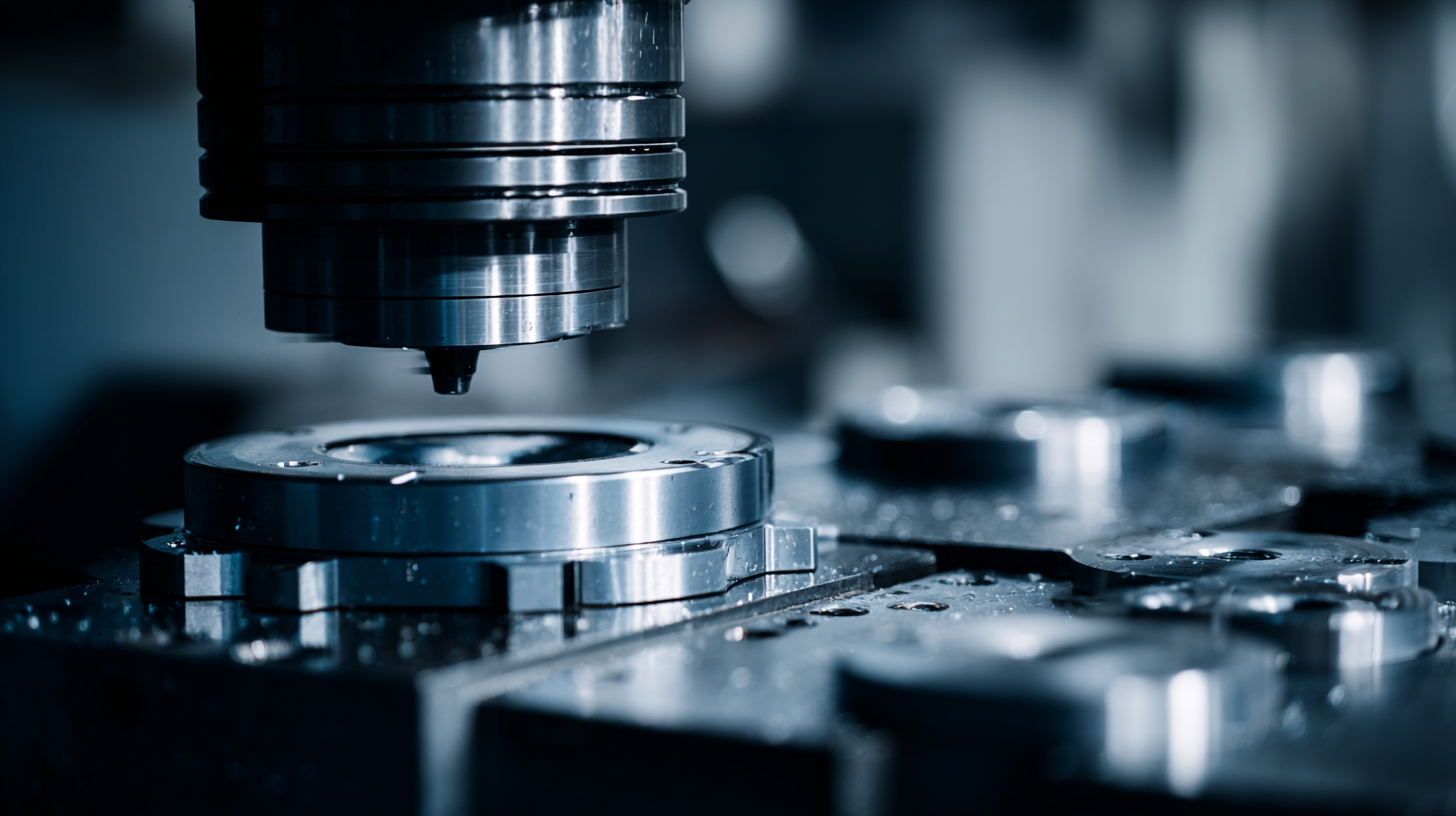

In recent years, China's precision metal machining industry has witnessed unprecedented growth, firmly establishing the nation as a global leader in this critical manufacturing sector. According to a report by Market Research Future, the global precision machining market is projected to reach USD 122 billion by 2026, with China contributing significantly to this growth due to its integration of advanced technologies and a skilled workforce. Precision metal machining plays a vital role across various industries, including automotive, aerospace, and electronics, where the demand for high-quality components continues to rise. With an increasing focus on quality and innovation, Chinese manufacturers are not only meeting domestic needs but are also expanding their presence in international markets, thereby setting new standards in precision metal machining. As a result, the commitment to quality in this sector could redefine manufacturing benchmarks globally, ensuring that China remains at the forefront of precision engineering excellence.

China's metal machining industry has established itself as a benchmark against global competitors, driven by a relentless pursuit of quality and precision. Recent studies indicate that the country has become a top player, with an annual growth rate of 10% in the precision machining sector. This is a direct result of adopting advanced technologies and emphasizing stringent quality control measures that meet international standards.

Benchmarking, especially in steel processing, has proven to be a vital practice for enhancing cost competitiveness. Companies that have engaged in disciplined benchmarking have reported significant reductions in operational costs and improvements in efficiency. For instance, firms implementing targeted performance metrics have seen up to a 15% increase in production efficiency and a decrease in waste by as much as 20%. As China continues to refine its machining processes and maintain competitive pricing, the country not only sets a high standard for metal machining excellence but also challenges global players to elevate their own practices to a new level of efficiency and quality.

China's manufacturing industry has gained global recognition for its commitment to quality, particularly in the domain of precision metal machining. This advanced process not only ensures high levels of accuracy but also supports the production of intricate components that meet the demanding standards of various sectors such as aerospace, automotive, and electronics. The precision metal machining processes employed in China enable manufacturers to deliver products that enhance performance and reliability, solidifying the country's position as a leader in the global market.

When considering precision metal machining, it's essential to prioritize quality over cost. Here are a few tips: first, always select manufacturers with a proven track record in quality assurance; this will help mitigate risks associated with defective parts. Second, ask for samples or prototypes before placing large orders; this ensures that the machining process aligns with your specifications and standards. Lastly, stay updated on the latest machining technologies and techniques, as innovation can greatly impact efficiency and precision.

Moreover, the advantages of precision metal machining extend beyond quality. It also offers enhanced efficiency, reducing waste and production time. By utilizing state-of-the-art equipment and highly skilled labor, Chinese manufacturers can optimize their production processes. To ensure success in precision metal machining ventures, collaborating with experienced partners and understanding the intricacies of the industry will be crucial.

China's rise to prominence in precision metal machining can largely be attributed to its relentless pursuit of technological innovations. With a strong emphasis on research and development, Chinese manufacturers have integrated cutting-edge technologies such as artificial intelligence, automation, and advanced robotics into their machining processes. This not only improves efficiency but also enhances precision, ensuring that even the most intricate designs can be realized with exceptional accuracy.

Moreover, China's commitment to quality control plays a pivotal role in solidifying its leadership in the global machining landscape. Through the implementation of sophisticated quality management systems and the adoption of international standards, Chinese firms are able to guarantee that their products meet the highest specifications. The convergence of technology and quality has positioned China as a global powerhouse in the precision metal machining sector, attracting businesses worldwide that seek reliability and excellence in their manufacturing partners.

China's precision metal machining industry has made remarkable strides, largely due to the unparalleled skills and expertise of its workforce. The combination of advanced technology and a dedicated talent pool positions China at the forefront of global machining quality. A skilled workforce not only enhances production efficiency but also ensures meticulous attention to detail, resulting in superior products that meet stringent international standards.

**Tip: Continuous Training and Development**

Companies should invest in ongoing training programs to keep their workforce updated with the latest machining techniques and technologies. This not only boosts employee morale but also increases overall productivity and quality.

Moreover, the collaboration between educational institutions and manufacturing firms is essential in refining the skills of new entrants into the workforce. By creating curriculums that focus on the specific needs of the machining industry, China can further elevate its quality standards.

**Tip: Embrace Technology and Automation**

Leveraging advanced technologies such as automation and AI can significantly enhance the precision of machining processes. As workers adapt to these technological tools, they can achieve more consistent outcomes, further solidifying China's reputation in the global market.

| Dimension | Value |

|---|---|

| Annual Output (Units) | 500,000 |

| Export Ratio (%) | 35% |

| Average Wage (USD) | 8,000 |

| Skilled Labor Force (Million) | 4.5 |

| Training Institutions | 300+ |

| R&D Investment (Billion USD) | 15 |

| Quality Certification Rate (%) | 90% |

| Industry Growth Rate (%) | 8% |

China's manufacturing sector has long been recognized for its vast scale and rapid production capabilities. According to the 2021 Global Manufacturing Competitiveness Index, China ranks as the top global manufacturing hub, thanks to its robust supply chain and highly skilled labor force. However, when evaluating cost efficiency against global standards, several pivotal factors emerge.

China's manufacturing sector has long been recognized for its vast scale and rapid production capabilities. According to the 2021 Global Manufacturing Competitiveness Index, China ranks as the top global manufacturing hub, thanks to its robust supply chain and highly skilled labor force. However, when evaluating cost efficiency against global standards, several pivotal factors emerge.

A report by the McKinsey Global Institute indicates that while labor costs in China have risen—averaging about $6,500 per year for manufacturing workers—this increase is still competitive compared to developed nations, where average labor costs exceed $21,000. Additionally, automation and investment in advanced technologies have significantly improved productivity rates in Chinese factories, often outpacing those in Europe and the United States. With precision metal machining, for instance, the ability to integrate industry 4.0 solutions has not only enhanced production efficiency but also reduced lead times, making Chinese manufacturers attractive to global partners seeking quality at a lower cost.

Furthermore, research from Deloitte highlights that China’s continuous investment in R&D is enabling the country to enhance its product quality and precision machining capabilities, gradually shifting its image from just being a low-cost manufacturer to a leader in sophisticated manufacturing solutions. As we observe these trends, it is clear that China’s commitment to balancing cost efficiency with high manufacturing standards places it at the forefront of the global market.