+86 180 0293 5268

+86 180 0293 5268

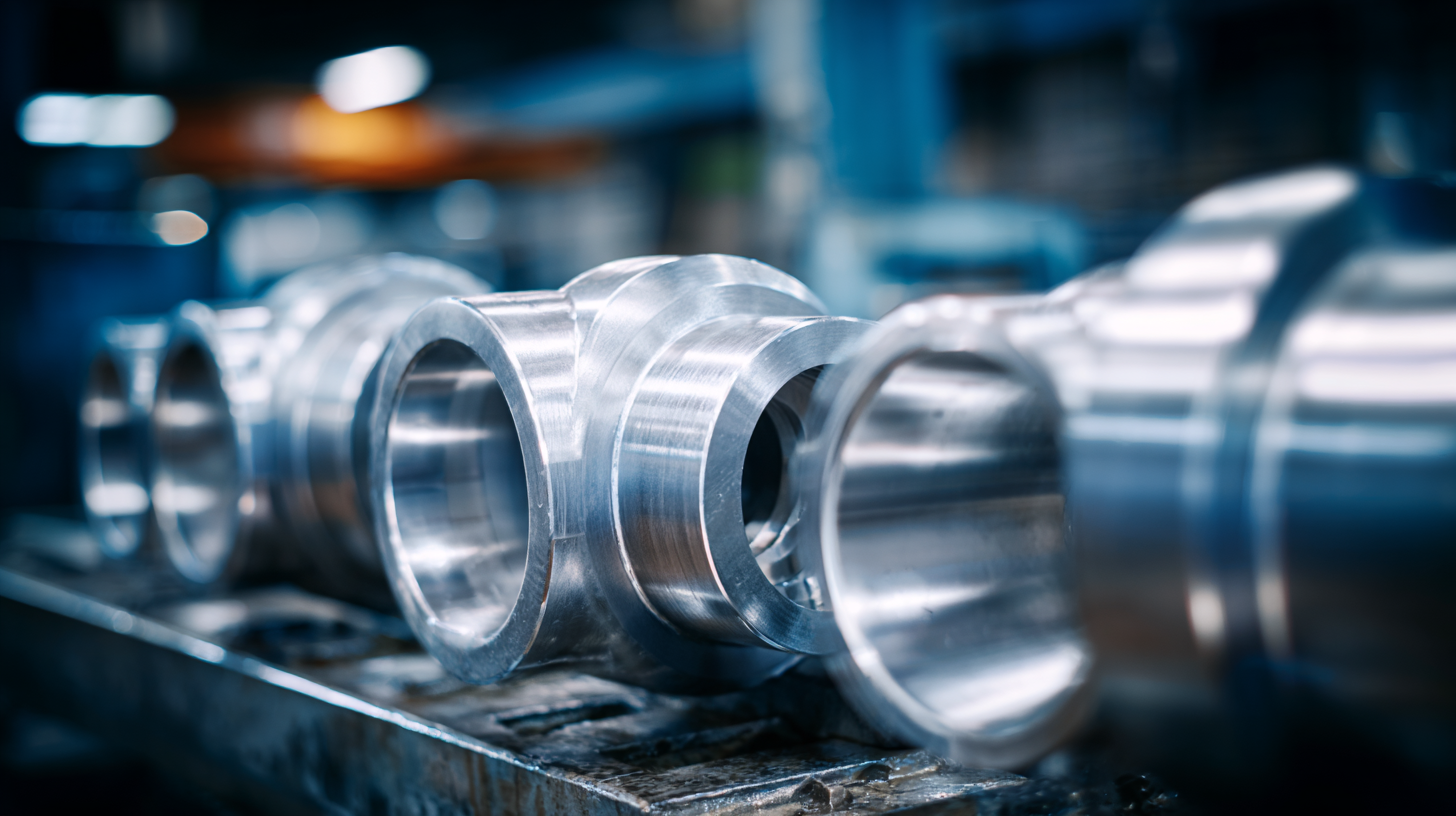

In the manufacturing industry, the selection of materials is crucial for ensuring product quality and longevity. Among various options available, Stainless Steel Castings stand out due to their exceptional durability, corrosion resistance, and versatility in application. However, choosing the best applications for stainless steel castings can be a daunting task for manufacturers, given the myriad of factors to consider, such as alloy composition, design requirements, and the specific operational environment. This guide aims to provide insights into how to effectively evaluate and select optimal applications for stainless steel castings, ensuring seamless integration into production processes while maximizing performance and cost-effectiveness. By understanding the key attributes and benefits of stainless steel castings, manufacturers can make informed decisions that enhance their product offerings and maintain a competitive edge in the market.

When selecting applications for stainless steel castings in manufacturing, it is crucial to identify the key factors that influence performance and compatibility. One significant factor is corrosion resistance, which is a hallmark of stainless steel. According to a study by the International Stainless Steel Forum, around 60% of stainless steel usage is attributed to its outstanding anti-corrosive properties. Therefore, applications in environments with high moisture or chemical exposure, such as food processing or marine industries, should prioritize stainless steel castings.

Another essential aspect to consider is the thermal and mechanical properties of stainless steel. ASTM International highlights that certain grades of stainless steel can withstand elevated temperatures without losing their structural integrity, making them ideal for applications in the aerospace and automotive sectors. Additionally, the strength-to-weight ratio is particularly important in these industries, where performance and efficiency are paramount. Leveraging technical data from industry reports helps manufacturers make informed decisions about which stainless steel casting applications will yield the best results in terms of durability and longevity.

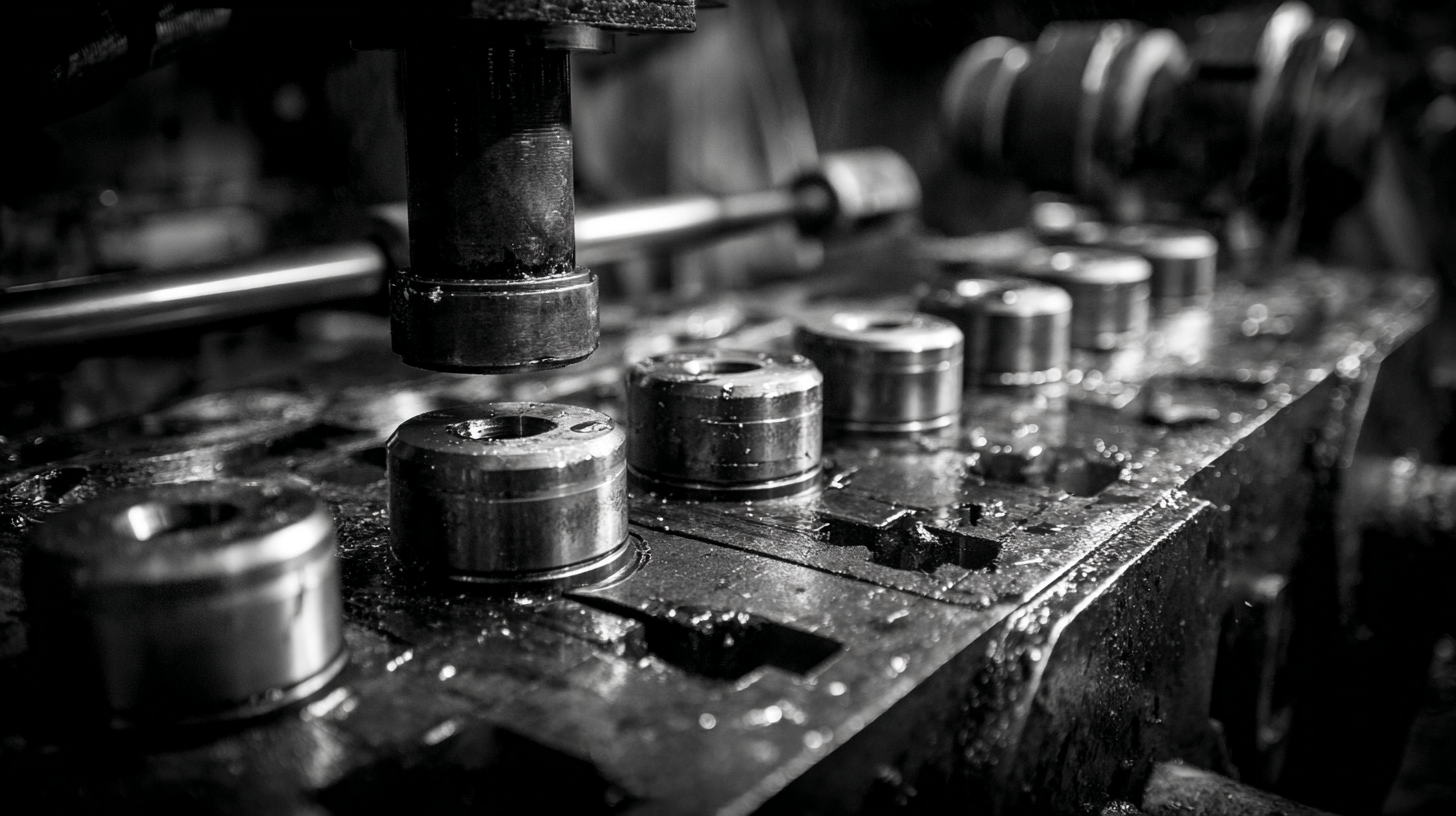

When selecting the best applications for stainless steel castings in manufacturing, it is essential to understand the unique characteristics of various stainless steel alloys and their specific uses. For instance, a recent study highlighted the role of manganese sulfide (MnS) in enhancing the intergranular corrosion resistance of sensitized Type 304 stainless steel. This insight is crucial in environments where corrosion and pitting are significant concerns, making Type 304 an ideal choice for food processing and chemical applications.

Another noteworthy alloy is 316 stainless steel, renowned for its superior resistance to corrosion in chloride environments, which is vital for marine and chemical industries. The stress corrosion cracking behavior of this alloy, particularly when exposed to high temperatures and pressures, has been thoroughly investigated, revealing insights that can enhance its applications in nuclear reactors.

Tips:

- When choosing a stainless steel alloy, consider the operating environment and potential exposure to corrosive elements.

- For high-temperature applications, select alloys like 600 and 316 that have demonstrated durability against crack growth under stress.

- Always consult material characterization reports to understand the properties and performance of the alloys under specific conditions.

When evaluating cost-effectiveness and performance metrics in casting applications for stainless steel, it is crucial to analyze both the immediate and long-term financial implications of different methodologies. The initial investment required for stainless steel castings may seem significant; however, assessing lifecycle costs—including maintenance, durability, and resistance to corrosion—can reveal the true economic advantages. Castings that offer a longer lifespan can mitigate replacement costs, ultimately leading to more favorable financial outcomes.

Performance metrics also play a vital role in determining the suitability of stainless steel castings for specific manufacturing needs. Key factors such as tensile strength, ductility, and thermal stability must be evaluated against the operational demands of the application. By conducting thorough performance analyses, manufacturers can ensure that chosen casting solutions not only meet their production standards but also enhance overall efficiency. Balancing these metrics with cost considerations allows companies to make informed decisions that drive productivity while ensuring financial viability.

Assessing environmental and regulatory compliance in manufacturing processes is crucial when selecting applications for stainless steel castings. The global push towards sustainability, driven by regulations such as the EU's REACH and RoHS directives, mandates that manufacturers adhere to stricter environmental standards. For instance, a report by the World Steel Association highlights that the steel industry is responsible for approximately 7% of global CO2 emissions, prompting companies to adopt eco-friendly practices. By choosing stainless steel castings, which are often recyclable and have a lower carbon footprint compared to other materials, manufacturers can align with these regulatory requirements while maintaining production efficiency.

Moreover, the growing awareness of environmental impacts has led to increased scrutiny from consumers and investors alike. According to a McKinsey & Company report, nearly 70% of investors now prioritize sustainability in their investment decisions. By ensuring compliance with environmental regulations, manufacturers not only mitigate the risk of legal penalties but also enhance their market competitiveness. Integrating compliance frameworks into manufacturing processes can involve adopting cleaner technologies and sourcing materials from suppliers that prioritize sustainable practices, ultimately fostering a more responsible production cycle.

| Application Area | Material Requirements | Environmental Compliance | Regulatory Standards | Notes |

|---|---|---|---|---|

| Automotive Components | Corrosion resistance, high strength | Recyclable materials, reduced emissions | ISO 14001 | Focus on lightweight designs |

| Industrial Machinery | Durability, thermal resistance | Emission controls, offline monitoring | OSHA regulations | Consider maintenance and accessibility |

| Construction and Building | High tensile strength, aesthetics | Sustainable sourcing, energy efficiency | LEED certification | Versatile applications in architecture |

| Food Processing Equipment | Non-reactive, easy to clean | Food-grade standards, waste management | FDA regulations | Focus on hygiene and safety |

| Marine Applications | High corrosion resistance, buoyancy | Impact on marine ecosystem, lifecycle analysis | ISO 9001 | Sustainability in material selection |

As the manufacturing sector continues to evolve, the application of stainless steel castings is gaining significant traction. With a projected market value of approximately $39.03425 billion in 2024 and an expected growth trajectory reaching $23.32 million by 2032, this sector is poised for remarkable expansion. Industry trends indicate a rising demand for durable materials that can withstand environmental stresses, which stainless steel castings readily provide due to their corrosion resistance and strength.

Moreover, advancements in manufacturing technologies, such as additive manufacturing and precision casting, are further enhancing the appeal of stainless steel castings in diverse applications. The increasing focus on sustainability and the circular economy is driving manufacturers to pursue high-quality materials that offer longevity and reduced waste. Reports from industry analysts highlight that stainless steel castings are becoming integral in sectors such as aerospace, automotive, and heavy machinery, predicting an increased adoption rate as companies seek to enhance product performance while minimizing their environmental footprint. This shift towards sustainable manufacturing practices is expected to reinforce stainless steel castings' vital role in future manufacturing landscapes.