+86 180 0293 5268

+86 180 0293 5268

In the rapidly evolving world of manufacturing, Precision Parts Machining has become a cornerstone of industrial efficiency. According to a report from the Precision Machined Products Association, the industry is projected to grow by over 5% annually. Finding the best Precision Parts Machining services is crucial for businesses aiming to maintain a competitive edge.

Jack Thompson, a leading expert in the field, once stated, "Quality and precision are the heartbeat of manufacturing." This highlights the importance of selecting a service provider that upholds these values. In an age where technology advances swiftly, the right machining service can enhance production speed and product reliability. However, not all machining services are created equal. Some may promise precision but fail to deliver consistent results.

Investing time in researching options is vital. A poor choice can lead to costly delays and subpar products. It’s easy to overlook small details that matter significantly, such as the technician's expertise and the machinery used. Balancing cost and quality is a perpetual challenge. The decision requires careful consideration to ensure long-term success in using Precision Parts Machining.

Precision parts machining is a critical process in many industries. It involves creating components to exact specifications. The importance lies in achieving tight tolerances. Such precision ensures that parts fit and function as intended. It affects performance, safety, and durability. Industries like aerospace and medical rely heavily on this precision. Any small error can lead to significant problems.

Understanding key concepts of precision machining is vital. Factors like material selection, tooling, and machining techniques play crucial roles. Each detail influences the final product's quality. A wrong choice can lead to defects and failures. Many may overlook this complexity. Overconfidence can lead to costly mistakes. Reflection on past projects can reveal areas for improvement.

The significance of precision cannot be overstated. Quality control measures are essential. They prevent errors and ensure consistency. Regular audits can identify weaknesses in the process. Embracing continuous improvement is important. Precision parts machining is not just a task; it's an art that requires ongoing learning. It demands diligence and a willingness to adapt.

When evaluating precision machining service providers, several criteria stand out. First, consider the technology they use. Advanced machinery ensures precise cuts and shapes. Moreover, look for services that offer a range of materials to work with. This flexibility can meet various project requirements.

Tips: Check if they provide prototypes. Prototypes allow you to assess quality before full production. It’s an essential step to avoid costly mistakes.

Experience also matters. A provider with a solid history is often more reliable. They are familiar with various industry standards. This experience translates to better quality control.

Tips: Ask for case studies or references. See how they handled past projects. It provides insight into their capability. Look for signs of innovation as well. Sometimes, older firms may rely too heavily on traditional methods.

Finally, communication plays a key role. A responsive provider can adapt better to your needs. If they are difficult to reach or slow to respond, consider it a red flag. Clear communication prevents misunderstandings and project delays.

| Criteria | Description | Importance Level |

|---|---|---|

| Machining Capabilities | Assessing the range of machining processes available, such as CNC machining, turning, milling, etc. | High |

| Quality Assurance | Evaluating the quality control processes and certifications, like ISO 9001. | High |

| Experience | Looking into the provider's experience in the industry and their track record. | Medium |

| Customer Reviews | Gathering feedback from previous clients regarding the service and product quality. | Medium |

| Lead Times | Evaluating the average turnaround time for orders and ability to meet deadlines. | High |

| Pricing Structure | Analyzing the cost of services compared to the overall value and quality offered. | Medium |

| Technical Support | Checking the availability of technical assistance and service flexibility. | Medium |

| Technology and Equipment | Reviewing the modern technologies and equipment used in the machining process. | High |

Precision machining techniques vary widely, each offering unique advantages depending on specific needs.

CNC machining is one of the most popular techniques. According to a recent industry report, it accounts for 45% of the precision machining market.

This method allows for high accuracy and repeatability. It uses computerized controls to cut materials with exceptional precision.

Another notable technique is electrical discharge machining (EDM). EDM excels in creating complex shapes.

It can work with hard metals that are challenging to machine through traditional methods.

The International Journal of Advanced Manufacturing Technology noted that EDM is often used in mold making, contributing to 25% of the custom machining market.

While these methods provide excellent results, they are not without challenges.

CNC machining might require extensive programming knowledge.

Inadequate programming can lead to defects.

EDM, on the other hand, may be slower and more expensive.

Understanding the pros and cons of each technique is crucial. This ensures you choose the right one for your project.

Ultimately, the decision should be influenced by the material, complexity, and precision required.

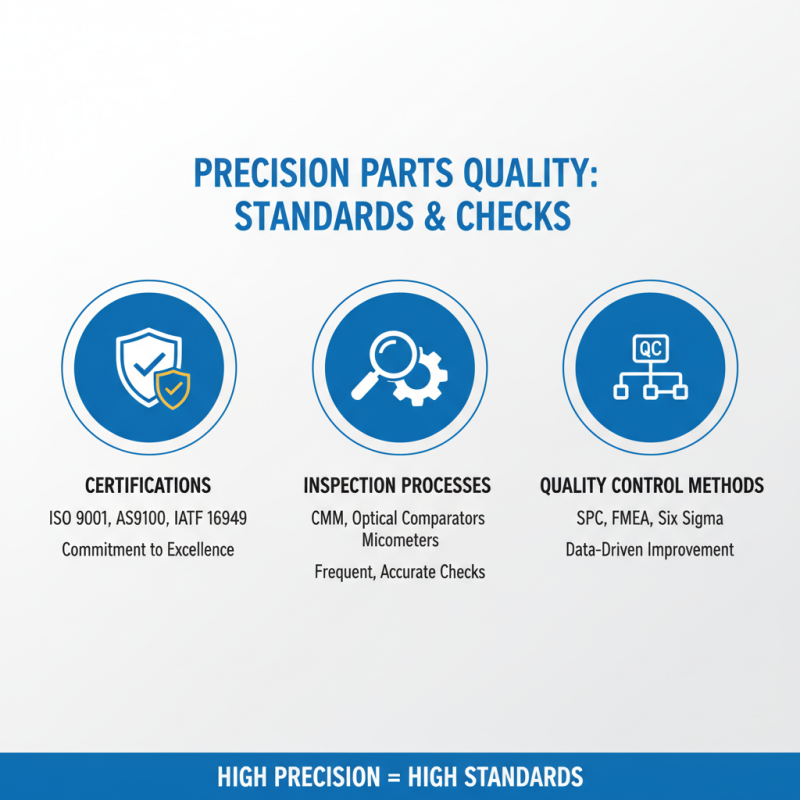

Assessing quality standards in precision parts manufacturing is crucial. Many factors come into play. Look for certifications that indicate a company’s commitment to quality. ISO standards are a good starting point. Inquire about inspection processes and quality control methods. High precision requires frequent checks and balances.

Materials used in machining also affect quality. Ensure they are suitable for your specific needs. Consider how these materials are sourced. This can impact reliability and performance. Some manufacturers may cut costs, leading to inferior products. Don't hesitate to ask for material certifications.

Customer feedback provides valuable insights. Reviews can reveal quality and service consistency. However, not all feedback is genuine. Some may be overly critical or too flattering. Use discretion when evaluating these comments. It’s important to conduct your research. A thorough approach helps ensure you choose a service that meets your quality expectations.

When considering precision parts machining services, cost is a significant factor. A survey by the National Association of Manufacturers indicated that nearly 70% of companies prioritize budget constraints when selecting suppliers. Balancing cost and quality is crucial. Many engineers struggle to find that sweet spot.

Quality machining services often come at a premium. Reports show that high precision can increase costs by 25% to 40%. However, inferior quality can lead to more expenses down the line. Companies may face after-sale issues, rework, and wasted materials. Such hidden costs can outweigh initial savings.

Moreover, as technology evolves, so do manufacturing processes. Investing in advanced machining technologies, although initially costly, can yield long-term gains. Consider collaboration with suppliers that offer flexible pricing models. This approach can ensure better alignment with your budget without compromising quality.