+86 180 0293 5268

+86 180 0293 5268

In today's competitive manufacturing landscape, selecting the appropriate Steel Casting Parts is crucial for optimizing both performance and cost-effectiveness in your projects. According to a recent report by MarketsandMarkets, the global steel casting market is projected to reach USD 46.6 billion by 2026, driven by increasing demand from various industries, including automotive, aerospace, and construction. Steel castings are renowned for their durability, excellent mechanical properties, and versatility in design, making them a preferred choice for high-stress applications. However, with the wide variety of materials, processes, and specifications available, the selection process can be daunting. Understanding the key factors that influence the performance and compatibility of Steel Casting Parts is essential to ensure that your project meets its objectives while adhering to budget constraints and quality standards.

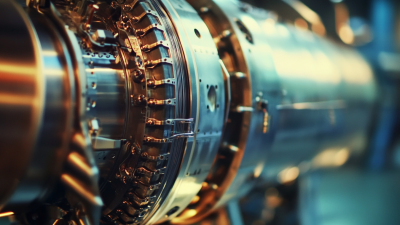

When selecting steel casting parts for your project, understanding the different types of steel casting processes is crucial. One of the most common processes is sand casting, which involves creating a mold from sand and pouring molten steel into it. This method is highly versatile and suitable for various complex geometries, making it ideal for large components used in industries such as automotive and construction.

Investment casting, also known as lost-wax casting, is another notable method. It is preferred for producing intricate designs with high precision, often used in aerospace and medical applications. The process involves creating a wax model, which is coated in a ceramic shell. Once the shell hardens, the wax is melted away, leaving a cavity for the molten steel. Each casting process has its unique advantages and applications, allowing for informed decision-making when choosing parts for specific project requirements. By comprehensively understanding these processes, you can select the most appropriate casting method to ensure the success of your project.

This chart illustrates the various steel casting processes and the number of units produced for each method. Sand casting leads in terms of production volume, while shell molding shows comparatively lower output.

When selecting steel casting parts for your project, it's essential to consider several key factors that can significantly influence the outcome. One major aspect is the temperature management throughout the casting process. Disturbances in the temperature field can lead to defects in the final product, such as shrinkage. Understanding and controlling the temperature during both the molds' creation and the metal pouring can help minimize these defects and enhance the quality of the castings. Implementing advanced methods and technologies for monitoring temperature can be beneficial in keeping these disturbances in check.

Another critical factor to consider is the market trends associated with steel casting parts as they may affect availability and cost. The global investment casting market is projected to grow significantly over the next decade, indicating a stable demand for high-quality steel components. Being aware of these trends can guide your sourcing decisions and budgeting, ensuring that you select parts that not only meet your technical specifications but are also economically viable. Ultimately, understanding the interplay between production conditions and market dynamics will help you make informed decisions for your steel casting needs.

When selecting the right steel casting parts for your project, understanding the material properties of various steel casting alloys is crucial. Each alloy possesses unique characteristics that can significantly influence performance, durability, and cost.

For instance, low-carbon steel is often favored for its excellent ductility and weldability, making it ideal for applications requiring extensive shaping and forming. On the other hand, high-carbon steel offers enhanced strength and hardness, suitable for heavy-duty applications and wear-resistant components.

Another critical alloy to consider is stainless steel, known for its corrosion resistance and aesthetic appeal. It’s commonly used in industries that demand high hygiene standards, such as food processing or medical equipment.

Cast iron, while technically not a steel, often comes into play when machinability and wear resistance are priorities. Each alloy presents trade-offs between strength, weight, and corrosion resistance, so evaluating the specific demands of your project will guide you in selecting the perfect steel casting parts to achieve optimal results.

When evaluating tolerances and finishes for precision steel castings, it is crucial to understand how these factors impact the overall quality and functionality of the final product. Tolerances dictate the allowable variations in dimensions, which can significantly affect the fit and performance of components in assembly. For instance, tighter tolerances are often required for parts that need to work in conjunction with others, such as in automotive or aerospace applications, where any discrepancy can lead to malfunction. Understanding the specific requirements based on the application will help you choose the right casting parts that meet those standards.

When evaluating tolerances and finishes for precision steel castings, it is crucial to understand how these factors impact the overall quality and functionality of the final product. Tolerances dictate the allowable variations in dimensions, which can significantly affect the fit and performance of components in assembly. For instance, tighter tolerances are often required for parts that need to work in conjunction with others, such as in automotive or aerospace applications, where any discrepancy can lead to malfunction. Understanding the specific requirements based on the application will help you choose the right casting parts that meet those standards.

Finishes, on the other hand, influence the aesthetic qualities and the resistance of parts to wear and corrosion. Different surface finishes, whether it be polished or rough, serve various purposes. For instance, a smoother finish may enhance the part's resistance to corrosion and improve its aesthetic appeal, while a rougher finish might be necessary for certain functional applications. Technological advancements in casting processes, including techniques like Metal Injection Moulding and Binder Jetting, allow for enhanced control over tolerances and surface finishes, paving the way for improved manufacturing capabilities and product performance. By considering both tolerances and finishes, you can make informed decisions that align with your project's specific needs.

When embarking on a project that requires steel casting parts, one of the most critical considerations is sourcing these materials in a cost-effective manner. A key strategy involves leveraging local suppliers, which can significantly reduce transportation costs and lead times. Building relationships with these suppliers not only fosters trust but also opens the door to potential bulk discounts.

Additionally, when assessing a supplier, consider their capacity to deliver quality castings consistently. Ensuring they adhere to strict quality standards can save you expenses on replacements or adjustments later in the project.

Another effective strategy is to conduct a thorough market analysis to compare prices and services across different suppliers. Utilize online platforms and industry forums to gather insights and reviews regarding their performance and reliability. Don't overlook the importance of looking for suppliers that offer comprehensive services, including design support and post-casting treatments. This can be especially beneficial, as it streamlines the process and can result in further savings by minimizing the need for external service providers for finishing or modifications. Adopting these practices will position your project for both success and cost efficiency.