+86 180 0293 5268

+86 180 0293 5268

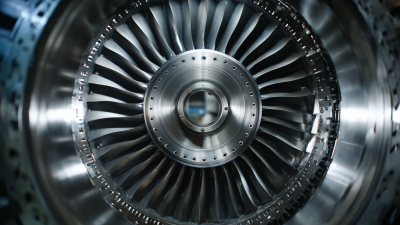

When it comes to selecting components for industrial applications, the choice of materials is crucial to achieving optimal performance and durability. Among various options, Steel Casting Parts have emerged as a favored choice due to their remarkable strength, versatility, and ability to withstand extreme conditions. Understanding how to choose the right Steel Casting Parts can significantly influence the efficiency and reliability of your machinery or equipment.

In this article, we will explore the key factors to consider when making this important decision. From assessing the specific requirements of your application to evaluating the casting processes and material properties, we aim to provide a comprehensive guide. Whether you are in the manufacturing, construction, or any other industrial sector, making an informed choice regarding Steel Casting Parts can lead to improved operational outcomes and longevity of your projects.

When selecting steel casting parts for industrial applications, it’s essential to understand the various types available and their specific characteristics. The most common types of steel casting include carbon steel, alloy steel, and stainless steel, each offering unique benefits. Carbon steel is known for its durability and ease of machining, making it a popular choice for many structural components. Alloy steel, on the other hand, provides enhanced strength and resistance to wear, making it suitable for heavy-duty applications. Lastly, stainless steel is favored for its corrosion resistance, making it ideal for environments where exposure to moisture and chemicals is a concern.

**Tips: When choosing steel casting parts, consider the environmental conditions of your application. For extended exposure to corrosive substances, opt for stainless steel casting. For high-stress applications, alloy steel may provide the necessary durability.**

Another vital aspect to consider is the manufacturing process of the casting parts, which can affect their overall quality and performance. Different techniques such as sand casting, investment casting, and die casting yield varying precision levels and surface finishes. Sand casting is often more economical for larger components, while investment casting is preferred for intricate designs requiring high dimensional accuracy.

**Tips: When assessing casting processes, evaluate both the component geometry and the required tolerances. Selecting an appropriate manufacturing method can lead to better performance and cost efficiency in the long run.**

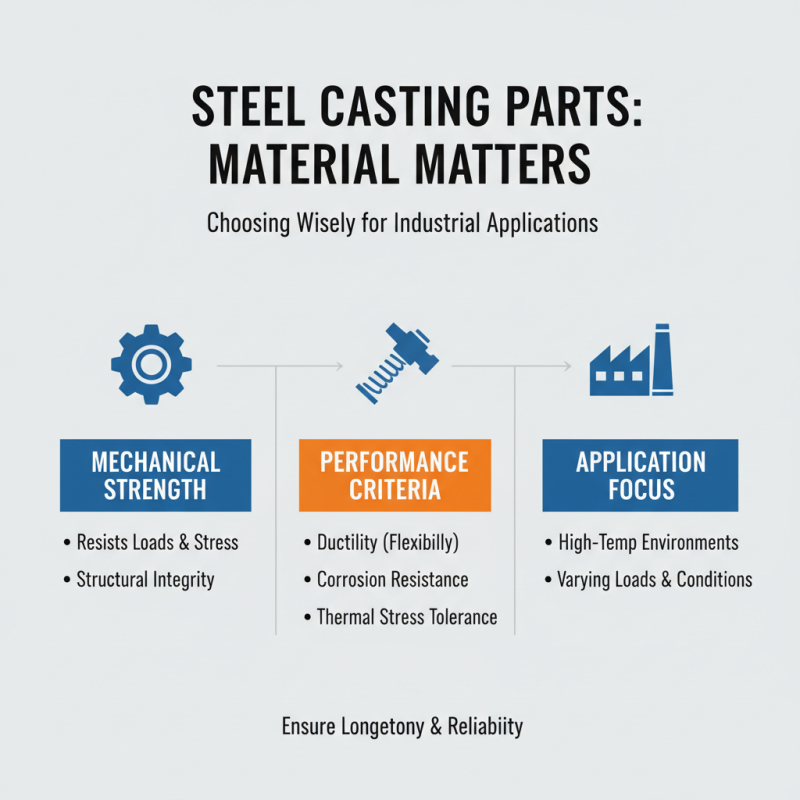

When choosing steel casting parts for specific industrial applications, understanding the material properties is crucial. Different applications require different mechanical strengths, ductility, and corrosion resistance qualities. For instance, components used in high-temperature environments may need steel alloys that can withstand thermal stresses without compromising structural integrity. It’s essential to evaluate how the material will perform under varying loads and environmental conditions to ensure longevity and reliability.

Tips: Always refer to the material specifications and test results to understand how a particular steel casting will behave in your application. Consider running simulations or stress tests for critical components to predict performance more accurately. This can help mitigate risks associated with material failure.

Moreover, compatibility with other materials in the assembly is an important factor. Steel casting parts might need to interface with plastics, composites, or other metals, so verifying compatibility can prevent issues like galvanic corrosion or thermal expansion mismatches. A thorough understanding of the properties of the casting material and its interactions will ensure a well-functioning assembly that meets your industrial needs.

Tips: Consult with engineering experts if you're uncertain about material compatibility or the specific requirements for your application. They can provide insights that help refine your material selection process, ensuring optimal performance and safety.

When selecting steel casting parts for industrial applications, evaluating tolerances and specifications is crucial to ensure optimal performance. According to a report by the American Foundry Society, precise tolerances can significantly influence the usability and functionality of casting parts, leading to variations in production efficiency by as much as 25%. In high-demand industries such as aerospace and automotive, where safety and reliability are paramount, adhering to stringent specifications is non-negotiable. This means that engineers must meticulously assess their design requirements against the manufacturing capabilities of steel casting processes to avoid issues like dimensional inaccuracies and material defects.

Moreover, understanding the specific mechanical and physical properties of the steel alloy used in casting is vital for performance optimization. The International Journal of Metalcasting highlights that different alloys can exhibit varying levels of strength, ductility, and resistance to wear and corrosion. For instance, tool steel might provide enhanced hardness but could compromise ductility, impacting the part's ability to absorb stress during operation. Thus, selecting the right alloy in conjunction with appropriate tolerances becomes an essential task to not only meet operational demands but also to extend the lifespan of the components while maintaining safety standards.

When selecting steel casting parts for industrial applications, cost and supplier reliability play pivotal roles in the decision-making process. Manufacturers must strike a balance between affordability and quality, as opting for the lowest price can sometimes lead to subpar materials that compromise the integrity of the final product. Conducting a thorough cost analysis is essential, but it should not overshadow the importance of establishing a reliable partnership with suppliers. A dependable supplier not only ensures that the materials meet industry standards but also provides valuable support through consistent communication and timely delivery.

**Tips:** Always request samples from potential suppliers to evaluate the quality of their steel casting parts before making a bulk order. Additionally, consider suppliers who have established reputations within your industry and seek customer testimonials to gauge their reliability. Setting up a long-term relationship can lead to better pricing and priority service, ultimately benefiting your operations.

Moreover, it is crucial to conduct background checks on suppliers. Look into their production capabilities, past projects, and certifications to ensure they adhere to quality standards. A reliable supplier will be transparent about their processes and willing to share information regarding their quality control measures. By prioritizing these considerations, you can make informed decisions that align with both your budget and the operational demands of your business.

| Part Type | Material Grade | Weight (kg) | Cost per Unit ($) | Lead Time (Weeks) | Supplier Rating (1-5) |

|---|---|---|---|---|---|

| Pump Housing | A536 Ductile Iron | 35 | 150.00 | 6 | 4 |

| Valve Body | ASTM A216 WCB | 25 | 120.00 | 4 | 5 |

| Gear Box Housing | G25 Grey Cast Iron | 50 | 200.00 | 8 | 3 |

| Crankshaft | AISI 1045 | 18 | 180.00 | 5 | 4 |

| Bracket Support | A356 Aluminum | 10 | 75.00 | 3 | 5 |

When selecting steel casting parts for industrial applications, maintenance and longevity are critical factors that can significantly affect performance and operational costs. The lifespan of steel casting components largely depends on their material properties, manufacturing processes, and application environments. Choosing high-quality steel materials with appropriate tensile strength and corrosion resistance is crucial to ensure that the parts can withstand the rigors of daily operations. Additionally, components subjected to extreme conditions—such as high temperatures or corrosive environments—must be carefully evaluated to ensure they meet these demands.

Proper maintenance protocols also play a pivotal role in extending the life of steel casting parts. Regular inspections and proactive maintenance can identify potential issues early, preventing costly failures and extending the overall service life of the components. Implementing standardized maintenance routines, such as cleaning and lubrication, can help protect against wear and corrosion. Furthermore, operators should be trained to recognize signs of fatigue or damage, allowing for timely interventions before problems escalate. By focusing on both the choice of materials and diligent maintenance practices, industries can enhance the reliability and functionality of their steel casting parts, ultimately leading to more efficient operations.