+86 180 0293 5268

+86 180 0293 5268

When embarking on a new project, selecting the appropriate manufacturing process can significantly influence the final product's quality, cost, and overall success. One such process that stands out in the realm of precision manufacturing is Investment Casting. Known for its ability to produce complex shapes with high accuracy and fine surface finishes, Investment Casting has become a favored choice for industries ranging from aerospace to medical devices. However, the selection of the right Investment Casting method is not a one-size-fits-all decision and requires careful consideration of various factors.

The decision-making process involves evaluating the specific requirements of your project, including material specifications, tolerances, and the intricacies of the design. Various techniques within Investment Casting, such as lost-wax or ceramic shell processes, offer distinct advantages that cater to different production needs. By understanding the nuances of each method, engineers and project managers can make informed choices that align with both technical requirements and budget constraints. This guide aims to provide a comprehensive overview of how to effectively choose the right Investment Casting process for your project, ensuring optimal results and efficiency.

When embarking on a project in 2025, understanding the various investment casting process variations is crucial to ensure success. Investment casting, also known as lost-wax casting, involves several adaptations tailored to specific material properties and geometrical requirements. For instance, the choice between traditional methods and advanced techniques such as 3D printing can significantly affect both the timeline and cost of production. It's essential to assess the project's specifications—such as the complexity of the part, the type of metal to be used, and the desired surface finish—before making a decision.

Moreover, different investment casting processes can accommodate a range of production volumes, from low to high. For projects that require precision and intricate designs, processes like ceramic shell investment casting may be preferable. Conversely, for projects requiring larger volumes with less intricate designs, metal mold casting might be more efficient. Therefore, evaluating these variations in processes not only aids in optimizing production efficiency but also aligns the project with budgetary constraints and quality expectations. Understanding these factors will empower stakeholders to make informed decisions tailored to their project's unique demands in 2025.

When selecting the right investment casting process for your project, it is crucial to consider several key factors that can significantly influence the outcome. One of the primary factors is the material requirements of the final product. Different investment casting methods are suited for various materials, such as ferrous and non-ferrous alloys, each with distinct properties that can affect performance and durability. Understanding the metallurgical characteristics of the materials required ensures that the chosen process can produce parts that meet the necessary specifications and quality standards.

Another important factor is the design complexity of the part being cast. Investment casting is known for its ability to create intricate geometries with excellent surface finishes. However, certain designs may require specific considerations regarding the mold-making process, venting, and feeding systems. Assessing the part design early on allows for the optimization of the casting process, ultimately leading to a more efficient production run with less waste and reduced lead times. Additionally, the projected quantity of parts needed can influence the choice of process, as some methods are more suitable for high-volume production while others are ideal for low-volume or custom jobs.

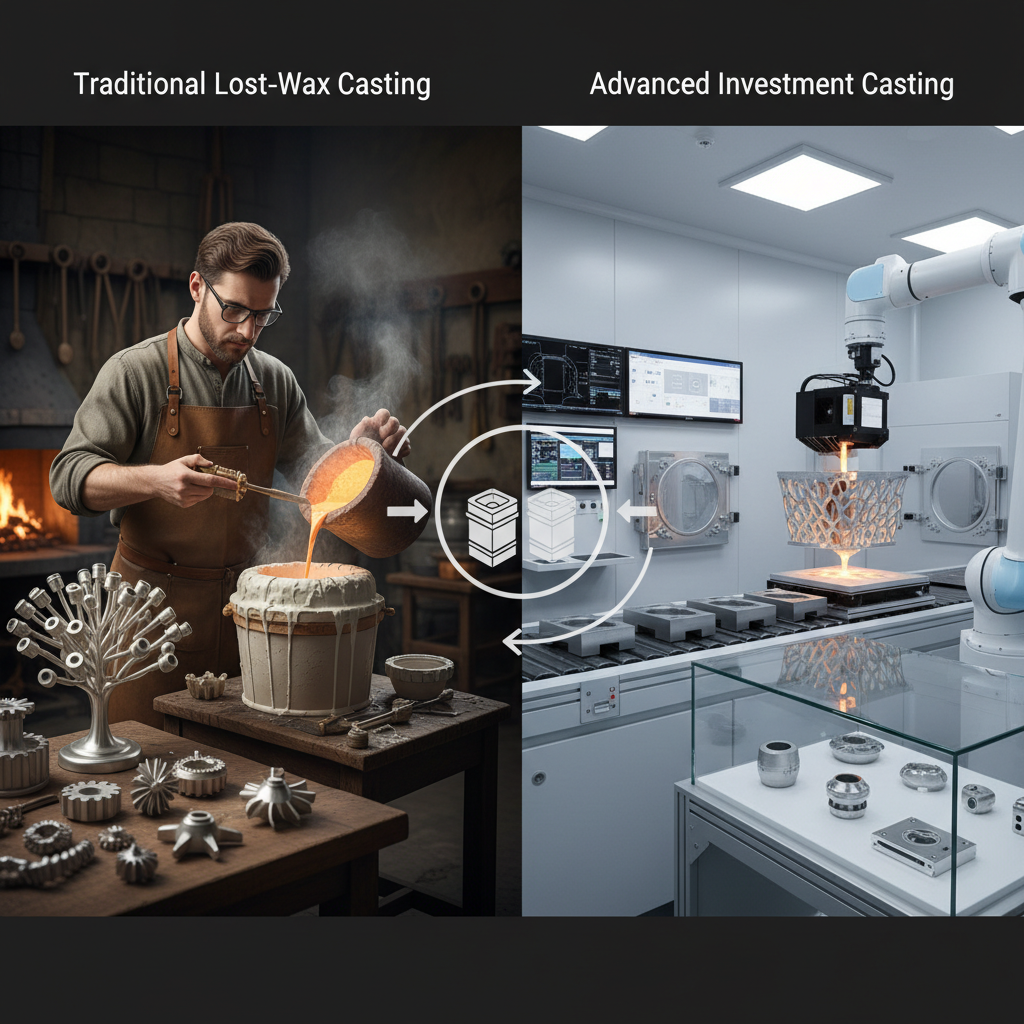

When selecting an investment casting process for your project, it is essential to understand the differences between traditional and advanced techniques. Traditional investment casting, often referred to as lost-wax casting, has been employed for centuries. This method involves creating a wax model that is coated in a ceramic shell to form an intricate mold. Once the mold is solidified, the wax is melted away, and molten metal is poured in. This technique is well-regarded for its precision and ability to produce complex geometries, making it suitable for low to medium production volumes where detail is paramount.

In contrast, advanced investment casting techniques incorporate modern technologies such as 3D printing and computer-aided design (CAD). These methods enhance efficiency and reduce lead times by allowing for rapid prototyping and customization. Advanced techniques also facilitate the use of a wider range of materials, including high-performance alloys that might not be feasible with traditional methods. By comparing these two approaches, project managers can make informed decisions that align with their specific manufacturing needs, cost considerations, and desired product specifications.

When embarking on an investment casting project, evaluating material compatibility is paramount. Investment casting offers a variety of materials, including stainless steel, aluminum, and bronze, each with distinct properties and applications. According to a market report by Mordor Intelligence, the investment casting market is projected to grow at a CAGR of 5.8% from 2021 to 2026, highlighting the increasing significance of selecting the appropriate material for both performance and cost-efficiency.

Different alloys exhibit varying degrees of strength, ductility, and corrosion resistance. For example, A356 aluminum is favored for lightweight structures due to its excellent mechanical properties and thermal conductivity, making it ideal for the aerospace and automotive industries. On the other hand, stainless steels such as 316L are preferred in environments where corrosion resistance is crucial, like in the marine and chemical sectors. As reported by the Global Investment Casting market analysis, the right material choice not only enhances the functionality of the final product but also impacts production costs and lead times significantly, emphasizing the need for careful material evaluation in investment casting decisions.

When evaluating the cost-effectiveness of different investment casting processes, it is crucial to consider both the initial setup and the long-term operational expenses. Each casting method—such as lost wax casting, ceramic shell casting, and others—comes with varying material costs, labor intensity, and production speed, influencing the overall budget. For instance, lost wax casting may require higher initial material investments but offers precision that can reduce machining costs in subsequent production stages.

In addition to direct costs, the scale of production plays a significant role in determining cost-effectiveness. Smaller runs may benefit from the lower setup costs of certain processes, making them more feasible despite higher per-unit costs. Conversely, for large-scale production, investing in more sophisticated casting technologies might be justified by lower unit costs due to increased throughput. Thus, a thorough analysis that considers both immediate and projected costs is essential for selecting the most suitable investment casting process for a project.

| Process Type | Typical Applications | Production Volume | Cost per Unit ($) | Lead Time (Weeks) |

|---|---|---|---|---|

| Silica Sol Process | Aerospace, Medical Devices | Low to Medium | 50 - 150 | 3 - 5 |

| Water Glass Process | Automotive, Hardware | Medium to High | 30 - 100 | 4 - 6 |

| Lost Foam Process | Industrial Equipment, Pumps | High | 20 - 80 | 6 - 8 |

| Shell Mold Process | Heavy Machinery, Marine | Medium | 40 - 120 | 5 - 7 |