+86 180 0293 5268

+86 180 0293 5268

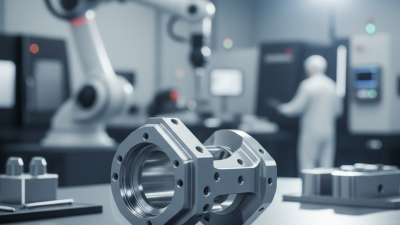

When embarking on a project that requires precision components, selecting the right precision parts machining service becomes a critical decision that can significantly influence the outcome of your venture. Precision parts machining, a process that involves the intricate fabrication of components with exacting tolerances and specifications, is essential across various industries including aerospace, automotive, and medical fields. Consequently, the importance of choosing a service provider that not only understands your specific needs but also possesses the right technology and expertise cannot be overstated.

In a market filled with numerous options, navigating through the maze of precision parts machining services can be quite daunting. Factors such as the provider's experience, the quality of their machinery, and their ability to adhere to strict deadlines should all be considered. Furthermore, it's crucial to assess their past performance and gather testimonials or case studies that reflect their capabilities. By doing so, you can ensure that the chosen service will meet your exact requirements, ultimately leading to a successful project outcome. The following sections will delve deeper into the criteria that should guide your selection process, empowering you with the knowledge to make an informed choice that enhances the effectiveness of your project.

Precision parts machining is a critical process in various industries, encompassing the creation of components that require meticulous accuracy and attention to detail. Understanding key terminologies is essential for effectively communicating project requirements with machining service providers. Terms like "tolerance" refer to the permissible limits of variation in a manufacturing process, dictating how closely a part must conform to its specified dimensions.

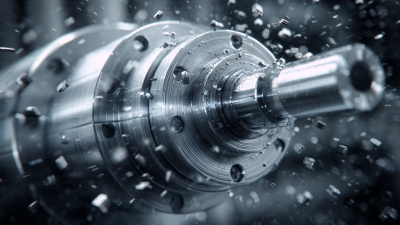

"CNC machining," another essential concept, stands for Computer Numerical Control machining, a method that utilizes computerized controls to operate machinery and ensure consistency and precision across multiple units.

Another important term is "workholding," which involves the fixtures and devices used to secure a workpiece during the machining process. Proper workholding is vital to achieving uniform results and maintaining quality control. Additionally, "material specifications" play a crucial role, as they determine the type of materials best suited for particular applications, impacting the strength, durability, and overall functionality of the machined parts. Grasping these terminologies not only aids in selecting the right precision machining service but also ensures that the end product aligns with the project’s specific needs and expectations.

When selecting a precision parts machining service, one of the critical factors to consider is the technical capabilities of the machining processes involved. CNC machining has increasingly become a preferred method over traditional machining techniques due to its superior accuracy and efficiency. Unlike traditional methods, which often rely on manual adjustments and tool changes, CNC machining utilizes computer-controlled equipment to execute precise cuts and designs. This automation reduces the risk of human error, enhances repeatability, and allows for the production of complex geometries that would be difficult, if not impossible, to achieve with manual techniques.

In addition to accuracy, the speed of production is another significant advantage of CNC machining. While traditional methods may require more time for setup and execution, CNC machines can operate continuously with minimal downtime. This allows manufacturers to produce larger quantities of parts in shorter timeframes, making it particularly beneficial for projects with tight deadlines. Furthermore, the flexibility of CNC technology enables adjustments to be made quickly, accommodating design changes without the extensive rework that traditional methods might necessitate.

Ultimately, evaluating these capabilities will play a crucial role in determining the most suitable machining service for your specific project needs.

When selecting a precision parts machining service, it is crucial to assess the quality assurance standards they uphold. Quality assurance (QA) is a systematic process that helps ensure that components meet precise specifications and regulatory requirements. A service provider should have certification to recognized standards, such as ISO 9001, which demonstrates their commitment to maintaining high-quality processes. This certification indicates that the company regularly audits its practices to continually improve and ensure that its machining services consistently produce parts that meet or exceed client expectations.

Additionally, it is important to inquire about the specific QA measures implemented during the machining process. Effective services utilize a range of inspection techniques, including dimensional and visual inspections, to verify that each part adheres to the specified tolerances. The implementation of advanced technologies, such as coordinate measuring machines (CMM), can further enhance quality control by providing accurate measurements that pinpoint any deviations early in the manufacturing process. By prioritizing a machining service with robust quality assurance practices, you can mitigate risks associated with defects and ensure the reliability of your project's components.

This chart illustrates the adoption rates of various quality assurance standards in precision machining services, highlighting the importance of choosing a service that meets these standards for project success.

When selecting a precision parts machining service, understanding cost considerations is pivotal.

Different machining service providers often employ various pricing models that can significantly impact your project budget. Some companies may offer fixed pricing based on the complexity and volume of parts required, while others might adopt a more flexible, hourly rate approach. It’s essential to assess the total cost implications of these models in relation to your project timeline and quality requirements.

Moreover, comparing pricing structures is not just about the numbers; it also involves evaluating what is included in the service. Some providers may offer comprehensive packages that cover design consultation, prototype development, and post-production support, while others might have a more segmented approach, charging separately for each aspect of the service. This could lead to additional unforeseen costs down the line.

Therefore, it’s crucial to obtain detailed quotes and clarify what each price point encompasses.

Doing so not only ensures transparency but also helps in making an informed decision that aligns with both your budget and project goals.

When selecting a precision parts machining service, one of the critical factors to consider is lead time. Timeliness is paramount in machining projects, as delays can impact your overall production schedule and project delivery. Analyzing lead times involves understanding the service provider's capacity, their production schedules, and their ability to meet deadlines. This is especially crucial for industries where time-to-market can significantly affect competitiveness.

To ensure that you select a machining service that understands the importance of timely delivery, it’s essential to ask the right questions during the evaluation process. Inquire about their typical turnaround times and how they handle unforeseen delays. This will help you gauge their reliability and responsiveness.

**Tips:** Always request historical data on lead times from potential machining partners. Additionally, it may be beneficial to review testimonials from previous clients regarding their experiences with project timelines. Building a good rapport with your service provider and maintaining open communication throughout the project can further ensure that timelines remain a top priority.