+86 180 0293 5268

+86 180 0293 5268

In today's manufacturing landscape, the efficiency and performance of CNC machining parts are crucial for achieving optimal operational outcomes. CNC (Computer Numerical Control) machining technology has revolutionized the production of precision components by allowing for greater accuracy, repeatability, and customization. As industries increasingly pivot towards automation and high-volume production, understanding the intricacies of CNC machining parts has become essential for engineers and manufacturers seeking to enhance their processes and deliver superior products.

This guide aims to provide an in-depth exploration of the essential factors that contribute to the optimal performance of CNC machining parts. By examining material properties, design considerations, and machining techniques, readers will gain valuable insights into selecting the right components to optimize production efficiency. Additionally, we will highlight best practices for maintenance and quality control, ensuring that the longevity and reliability of CNC machining parts meet industry standards. With this knowledge, professionals can make informed decisions that drive innovation, minimize waste, and maximize productivity in their operations.

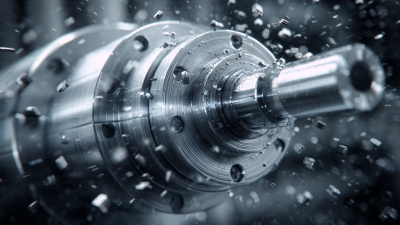

CNC (Computer Numerical Control) machining represents a sophisticated method that employs computer technology to control machine tools, ensuring precise and efficient production of parts. The technology integrates advanced programming techniques that allow for the automation of processes such as drilling, milling, cutting, and grinding. By utilizing CAD (Computer-Aided Design) software, engineers can create detailed schematics that guide the CNC machines in producing complex geometries with high accuracy and repeatability.

Understanding the key principles behind CNC machining is essential for optimizing performance and efficiency. The main concepts include understanding the type of materials being used, selecting appropriate tooling and speeds, and fine-tuning machine settings. Each aspect plays a crucial role in how effectively a CNC machine operates. Additionally, knowledge of CNC programming languages like G-code and M-code is vital for making the necessary adjustments to improve productivity. Through continuous advancements in technology, CNC machining remains at the forefront of manufacturing, delivering not only high-quality components but also allowing for greater flexibility and cost-effectiveness in production runs.

| Part Name | Material | Precision (mm) | Surface Finish | Applications |

|---|---|---|---|---|

| Bracket | Aluminum | 0.01 | Anodized | Mounting Components |

| Gear | Steel | 0.005 | Ground | Transmission Systems |

| Housing | Plastic | 0.02 | Textured | Enclosures |

| Shaft | Stainless Steel | 0.01 | Polished | Rotating Equipment |

| Plate | Titanium | 0.01 | Machined | Aerospace |

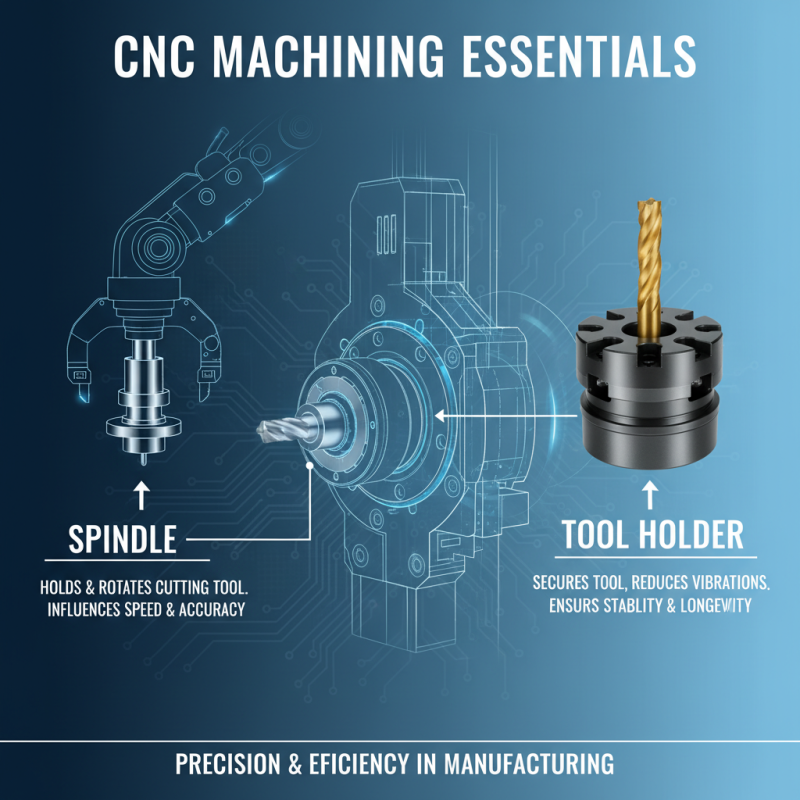

CNC machining relies on several essential components that work together to achieve precision and efficiency in manufacturing. One of the most critical parts is the spindle, which holds the cutting tool in place and controls its rotation. The quality and design of the spindle significantly influence cutting speed and accuracy, making it crucial for optimal performance. Additionally, the tool holder is essential for securely clamping the cutting tool, providing stability and reducing vibrations during the machining process. This ensures a smoother operation and extends the life of the tools used.

Another vital component is the coolant system, which regulates the temperature of both the tool and the workpiece during machining. Effective cooling reduces thermal expansion and wear, leading to better surface finishes and longer tool life. Moreover, the CNC machine's axis drives and support structures, such as linear guides and ball screws, play a significant role in the movement and positioning of the cutting tool. These elements must be precisely engineered to minimize backlash and ensure the reliable performance of the CNC machine. When properly configured, these essential parts significantly enhance the efficiency and quality of the machining process, leading to better overall productivity in manufacturing operations.

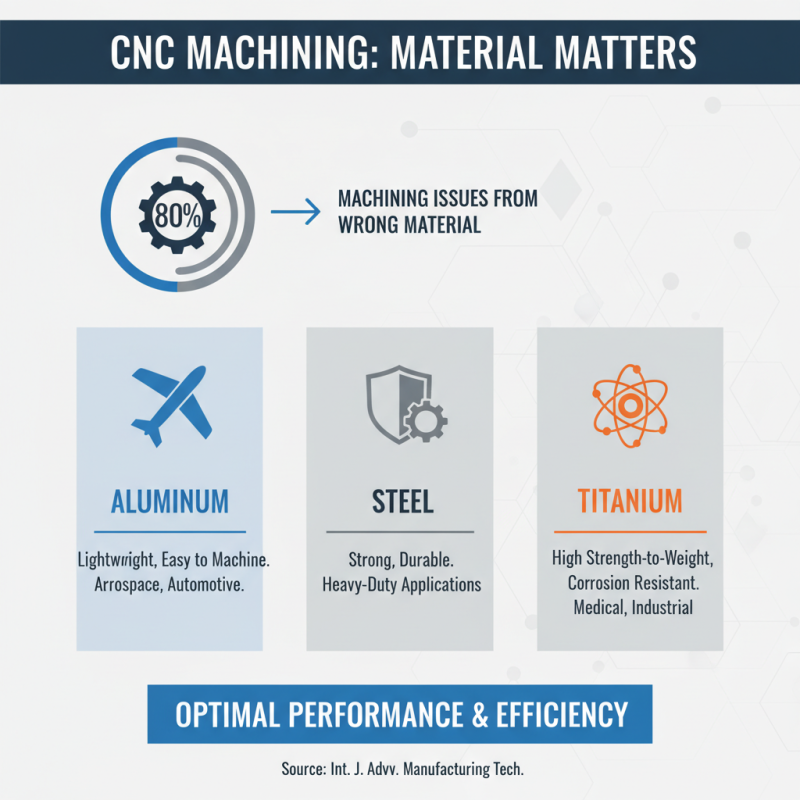

When it comes to CNC machining, the selection of materials plays a critical role in ensuring optimal performance and efficiency. According to a report by the International Journal of Advanced Manufacturing Technology, approximately 80% of machining issues can be traced back to inappropriate material selection. Commonly utilized materials include aluminum, steel, and titanium, each offering distinct benefits depending on the application. For instance, aluminum is favored for its lightweight nature and excellent machinability, making it suitable for industries such as aerospace and automotive. Meanwhile, steel provides enhanced strength and durability, ideal for heavy-duty applications.

Furthermore, the importance of material properties cannot be overstated. A recent study by the Manufacturing Institute highlighted that the thermal conductivity, hardness, and corrosion resistance of materials significantly influence tool wear and machining precision. For example, materials with higher hardness levels might require specialized tools, ultimately impacting production rates. Similarly, low thermal conductivity materials enable better heat dissipation, thereby extending tool life and enhancing machining accuracy. Thus, understanding the material characteristics is vital for achieving the desired output and efficiency in the CNC machining process.

Optimizing CNC Machining for Efficiency involves a multi-faceted approach. Understanding the interplay between machine parameters, tooling, and materials is critical for achieving high-performance outcomes. According to a recent industry report by Deloitte, optimizing cutting speeds and feeds can increase machining productivity by up to 30%. By adjusting the spindle speed in accordance with the material properties, manufacturers can substantially reduce cycle times while maintaining the quality of the finished parts.

Furthermore, the implementation of predictive maintenance strategies has been shown to enhance operational efficiency. A study from the National Institute of Standards and Technology indicates that companies employing predictive maintenance can realize a 12% reduction in maintenance costs and a 30% decrease in unplanned downtime. Regular monitoring of machine conditions and performance metrics allows operators to make informed decisions, minimizing interruptions and ensuring a consistent production flow. Together, these practices create a robust framework that supports both optimal performance and efficiency in CNC machining environments.

CNC machining is a vital process in modern manufacturing, known for its precision and efficiency. However, as with any advanced technology, issues can arise, impacting performance and productivity. Common problems include tool wear, misalignment, and programming errors, each of which can lead to significant downtime and increased costs. According to a report by the Association for Manufacturing Technology, misalignment can account for up to 30% of production inefficiencies in CNC systems.

To address these challenges, a systematic troubleshooting approach is essential. First, regular maintenance schedules should be established to check for signs of tool wear, ensuring that tools are replaced or reconditioned promptly. Additionally, calibration protocols must be adhered to, as misalignment due to improper setup can severely compromise machining accuracy. Incorporating real-time monitoring systems can further enhance performance by providing immediate feedback on machine conditions, leading to proactive adjustments. A study from the National Institute of Standards and Technology indicated that implementing such monitoring can reduce unexpected machine failures by as much as 25%.

Furthermore, programming errors, often due to complex CAD/CAM integrations, can generate costly mistakes in production runs. Training staff in efficient programming practices and having a robust review system for CNC codes can mitigate these issues. A comprehensive analysis by the Institute for Advanced Manufacturing revealed that organizations that prioritize staff training in these areas can see up to a 15% increase in operational efficiency. By focusing on these key areas, manufacturers can significantly resolve common CNC machining issues, ensuring optimal performance and efficiency in their operations.