+86 180 0293 5268

+86 180 0293 5268

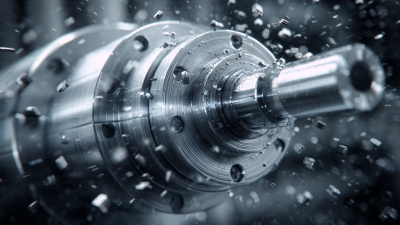

In recent years, the manufacturing industry has seen significant advancements in technology, paving the way for more efficient and precise methods of production. One such method, CNC milling parts, has gained popularity for its ability to achieve intricate designs and tight tolerances that traditional machining techniques often struggle to meet. According to a report by Markets and Markets, the global CNC machining market is projected to reach $100 billion by 2026, highlighting the rising demand for automated manufacturing solutions.

CNC milling not only enhances productivity but also reduces waste, providing an environmentally friendly alternative to conventional machining. As industries seek to optimize their operations, understanding the differences between CNC milling parts and traditional techniques becomes essential for selecting the best manufacturing solution for specific applications. This exploration offers insight into how these approaches stack up against each other, guiding businesses toward informed decisions in their machining strategies.

CNC (Computer Numerical Control) milling has revolutionized the manufacturing landscape, particularly in producing precision parts compared to traditional machining techniques. According to a report by the International Journal of Advanced Manufacturing Technology, CNC milling can achieve tolerances as tight as ±0.005 inches, significantly more precise than the ±0.025 inches generally attainable through conventional methods. This exceptional precision is facilitated by automated systems that eliminate human error, ensuring consistent results across large production runs.

Moreover, the speed and efficiency of CNC milling contribute to its precision advantage. Studies by the Society of Manufacturing Engineers indicate that CNC machinery can operate at speeds up to 10 times faster than manual machining processes. This rapid production capability not only minimizes lead times but also allows for complex geometries and intricate designs that traditional methods often struggle to replicate. As a result, industries such as aerospace and automotive, which demand high precision and reliability, have increasingly adopted CNC milling as their manufacturing standard, underscoring the technology's crucial role in modern production.

| Feature | CNC Milling Parts | Traditional Machining Techniques |

|---|---|---|

| Precision | High precision up to ±0.01 mm | Moderate precision up to ±0.1 mm |

| Production Speed | Fast setup and production for large volumes | Slower due to manual setup |

| Complexity of Parts | Able to produce complex geometries easily | Limited to simpler designs |

| Material Versatility | Compatible with various materials including metals, plastics, and composites | Typically limited to metals and some plastics |

| Labor Costs | Lower labor costs due to automation | Higher labor costs due to skilled manual labor |

| Setup Time | Shorter, thanks to computer programming | Longer, requiring manual adjustments |

| Scalability | Highly scalable for large production runs | Less scalable, better for small batches |

When it comes to cost efficiency in manufacturing,

CNC milling parts have distinct advantages over traditional machining methods. A report by the

International Journal of Advanced Manufacturing Technology indicates that CNC milling can reduce production costs by up to 30% in comparison to conventional techniques.

This is primarily due to the precision and automation that CNC machinery provides, resulting in less material waste

and shorter processing times.

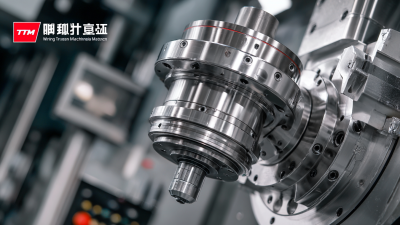

One key point to consider is the helix angle of the mill cutter.

When the helix angle is large, the axial force on the end mill tends to increase, reducing the radial force and the vibrations during operation.

This not only enhances the surface finish of the workpiece but also significantly contributes to tool longevity, thus lowering replacement costs over time.

Additionally, implementing CNC technology allows for complex geometries to be machined with ease,

which would require multiple setups in traditional machining.

Tip: To maximize the cost efficiency of CNC milling, operators should ensure

proper tool selection based on the material being used and the desired finish. Additionally, regular maintenance of the CNC machine can prevent downtime

and further reduce operational costs. Always keep an eye on new developments in machining techniques to optimize production processes.

In today's manufacturing landscape, CNC milling has emerged as a pivotal technique, particularly when it comes to flexibility and customization. Unlike traditional machining methods, which often rely on fixed sets of tooling and limited adjustments, CNC (Computer Numerical Control) milling allows for rapid reconfiguration and precise adjustments, making it highly adaptable to diverse production needs. According to a report by MarketsandMarkets, the CNC machining market is projected to reach $100 billion by 2026, highlighting the increasing reliance on these technologies for complex and varied tasks.

One of the most significant advantages of CNC milling is its capacity for customization. Manufacturers can easily modify designs based on specific client requirements or evolving product specifications. In a study conducted by Technavio, it was found that over 35% of firms prefer CNC milling for producing low-volume customized parts, thanks to its ability to minimize lead times and reduce waste. This flexibility is crucial in sectors like aerospace and automotive, where adaptability and precision are paramount. By leveraging CNC technology, companies can not only meet the sophisticated demands of their clients but also enhance overall production efficiency.

The manufacturing landscape is undergoing a significant transformation thanks to CNC (Computer Numerical Control) technology, which offers unparalleled speed and efficiency compared to traditional machining techniques. As the global machine tool market is projected to grow from $13.63 billion in 2025 to $22.946 billion by 2032, with a compound annual growth rate (CAGR) of 8.1%, it's clear that businesses are increasingly investing in the automation and precision that CNC technology provides.

Particularly, the CNC machining center market is expected to expand from approximately $14.348 billion in 2025 to over $21.694 billion by 2033, reflecting a 5.7% CAGR. This uptick illustrates the rising demand for high-speed machining capabilities across various industries. Moreover, the global CNC controller market is predicted to increase from $33.666 million in 2025 to $228.7 million by 2033, indicating a stable growth rate of 2.2%. This surge in CNC adoption underscores a crucial shift towards digital manufacturing technologies, driven by the need for high precision and operational efficiency. As manufacturers adopt these advanced solutions, they enhance their competitiveness and adapt to the evolving market demands.

CNC milling has revolutionized manufacturing by providing enhanced quality control compared to traditional machining techniques. The precise programming inherent in CNC processes allows for consistent output and reduced variability in product quality. Unlike traditional techniques, where human error can influence the manufacturing process, CNC milling employs advanced algorithms and automation, ensuring that each part produced meets the predefined high-quality standards. This is particularly critical in industries like medical device fabrication, where tolerances must be meticulously maintained.

CNC milling has revolutionized manufacturing by providing enhanced quality control compared to traditional machining techniques. The precise programming inherent in CNC processes allows for consistent output and reduced variability in product quality. Unlike traditional techniques, where human error can influence the manufacturing process, CNC milling employs advanced algorithms and automation, ensuring that each part produced meets the predefined high-quality standards. This is particularly critical in industries like medical device fabrication, where tolerances must be meticulously maintained.

Tip: To enhance quality control in CNC milling, consider integrating AI-powered monitoring systems that can predict tool wear and conditions in real time. This proactive approach can help mitigate potential defects before they affect production outcomes.

Moreover, as the demand for complex designs continues to rise, CNC milling allows manufacturers to efficiently work with harder materials whilst achieving intricate features without compromising dimensional tolerances. This adaptability is a significant advantage over traditional machining methods.

Tip: Regularly evaluate your CNC programming and operational settings to identify areas for improvement. Small adjustments can lead to significant increases in efficiency and quality over time.