+86 180 0293 5268

+86 180 0293 5268

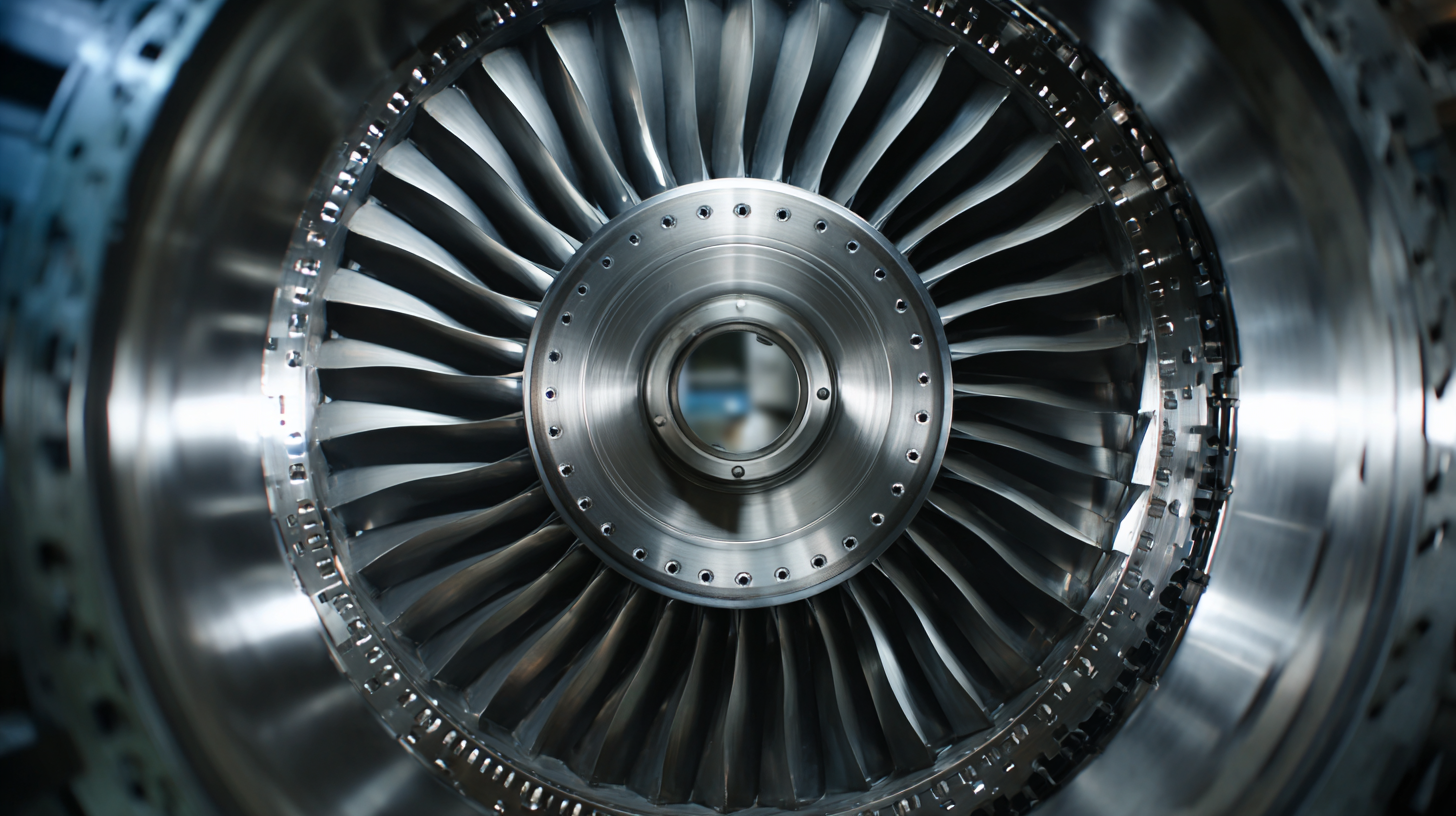

In the ever-evolving field of Aerospace Machining, the pursuit of excellence is both a challenge and an opportunity. As the industry continues to advance, traditional machining methods often fall short in meeting the demanding requirements of precision, efficiency, and sustainability. This blog delves into alternative solutions that harness the power of digital technologies combined with best practices in machining. By exploring innovative strategies, tools, and techniques, we aim to uncover new pathways to enhance productivity and quality in Aerospace Machining.

Through this exploration, we will highlight how embracing a "digital plus best" approach can not only streamline processes but also propel the aerospace sector into a new era of manufacturing excellence. Ultimately ensuring that the rigorous standards of safety and reliability are met with every machined component.

As the aerospace industry continues to evolve, innovative techniques in machining are becoming paramount for enhancing manufacturing efficiency and precision. For 2025 and beyond, technologies such as advanced computer numerical control (CNC) machining, additive manufacturing, and automated inspection systems are set to redefine traditional processes. These innovations not only reduce cycle times but also improve the quality of components, allowing manufacturers to meet the stringent requirements of aerospace applications.

One of the most promising advancements is the integration of artificial intelligence (AI) into machining operations. AI-driven systems can analyze vast amounts of data to optimize cutting parameters in real-time, leading to greater surface finishes and reduced wear on tools. Additionally, the adoption of hybrid manufacturing processes, which combine additive and subtractive methods, offers unprecedented flexibility and complexity in producing intricate aerospace components. As we approach 2025, embracing these technologies will be crucial for companies aiming to achieve machining excellence in an increasingly competitive market.

The aerospace industry is undergoing a transformation with the integration of smart manufacturing technologies. These advancements are not only enhancing precision machining but also improving overall efficiency. By adopting IoT devices, AI-driven analytics, and automation, manufacturers can streamline operations and reduce waste, paving the way for excellence in aerospace machining.

The aerospace industry is undergoing a transformation with the integration of smart manufacturing technologies. These advancements are not only enhancing precision machining but also improving overall efficiency. By adopting IoT devices, AI-driven analytics, and automation, manufacturers can streamline operations and reduce waste, paving the way for excellence in aerospace machining.

Tip: Invest in an integrated manufacturing platform that combines data collection, analysis, and real-time monitoring. This will provide insights into machine performance and help identify areas for improvement.

Furthermore, implementing predictive maintenance powered by AI can significantly minimize downtime and prolong the lifespan of machining equipment. This proactive approach allows manufacturers to anticipate failures and schedule repairs before issues escalate, thereby maintaining consistent production quality.

Tip: Consider using machine learning algorithms that analyze historical data to forecast maintenance needs accurately. This not only saves costs but also enhances operational reliability. Embracing these smart technologies positions aerospace manufacturers to achieve unparalleled machining excellence and stay competitive in a rapidly evolving market.

Sustainability practices are increasingly transforming the aerospace machining sector, driven by the industry's commitment to reduce its carbon footprint and enhance operational efficiency. According to a report by Deloitte, the aerospace industry is anticipated to reach a market size of $1 trillion by 2030, with a significant portion of this growth fueled by sustainable manufacturing technologies. The adoption of advanced materials and energy-efficient machining processes is not only helping companies comply with stringent environmental regulations but also resulting in substantial cost savings. For instance, the implementation of hybrid machining solutions, which combine additive and subtractive manufacturing, can reduce material waste by up to 60%, a crucial factor in lowering overall production costs.

Moreover, the rise of sustainable machining practices, such as the use of biodegradable cutting fluids and the recycling of metal chips, showcases an industry-wide shift towards greener operations. According to a study from the International Aerospace Quality Group (IAQG), more than 50% of aerospace manufacturers are now incorporating sustainability measures into their production lines. This transition not only enhances the industry's image but also attracts environmentally-conscious customers and investors. By embracing these alternative solutions, aerospace machining companies are not just aiming for excellence in quality and precision but are also setting a benchmark for sustainability in manufacturing.

In the aerospace industry, achieving precision is paramount, and advanced tooling solutions play a crucial role in this quest for excellence. As manufacturers strive for higher efficiency and accuracy, innovations such as 3D-printed components and specialized carbide tools are revolutionizing machining processes. These technologies not only enhance precision in manufacturing but also reduce lead times and costs, making them indispensable for aerospace applications.

The rising trend towards electric vehicles is pushing the boundaries of precision tooling even further. As this sector evolves, manufacturers are recognizing the necessity for advanced machining capabilities that can meet the stringent demands of the aerospace domain. The growth of the precision tool market, projected to reach significant milestones by 2033, underscores the increasing investment in technologies that promote accuracy and sustainability. This evolution is not merely a response to market trends but also a strategic drive towards Atmanirbharta, reinforcing the commitment to self-sufficiency in aerospace manufacturing ecosystems.

| Tooling Type | Material | Precision (μm) | Performance (% Efficiency) | Application Areas |

|---|---|---|---|---|

| CNC Machining Tools | High-Speed Steel | 5 | 95 | Aero Engine Components |

| Laser Cutting Tools | Ceramic | 2 | 90 | Wing Structures |

| Precision Grinding Tools | Diamond | 1 | 98 | Fuselage Panels |

| 3D Printing Tools | Titanium Alloy | 10 | 80 | Auxiliary Structures |

In the rapidly evolving aerospace industry, collaboration stands out as a key strategy to address the multifaceted challenges associated with machining excellence. Partners from various sectors, including manufacturers, technology providers, and academic institutions, are converging to share best practices and innovations that enhance machining processes. This collaborative spirit fosters a creative environment where shared knowledge can lead to breakthroughs in efficiency, precision, and sustainability—crucial factors in aerospace machining.

Furthermore, industry forums and joint research initiatives are proving invaluable in identifying common pain points faced by machinists and engineers. By pooling resources and expertise, stakeholders can tackle complex issues such as material wastage, process optimization, and quality assurance. These collective efforts not only streamline machining operations but also pave the way for the development of cutting-edge technologies, like advanced tooling and automation solutions, which can elevate the industry standard and help companies achieve long-term excellence in aerospace machining.