+86 180 0293 5268

+86 180 0293 5268

As manufacturing continues to evolve, the role of CNC machined parts becomes increasingly pivotal in innovative production techniques. According to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 100 billion by 2025, driven by advancements in automation and precision engineering. The integration of CNC machined parts in manufacturing processes not only enhances product quality but also significantly reduces production times and costs.

With the rise of Industry 4.0, characterized by smart manufacturing and IoT, the demand for precision components has surged, placing CNC machined parts at the forefront of this transformation. This evolution is further highlighted in a study by Grand View Research, which estimates the global CNC machining market will expand at a CAGR of 6.0% from 2022 to 2030. As manufacturers adapt to these innovative techniques, understanding the future landscape of CNC machined parts becomes essential for maintaining competitive edge and operational efficiency.

With the rise of Industry 4.0, characterized by smart manufacturing and IoT, the demand for precision components has surged, placing CNC machined parts at the forefront of this transformation. This evolution is further highlighted in a study by Grand View Research, which estimates the global CNC machining market will expand at a CAGR of 6.0% from 2022 to 2030. As manufacturers adapt to these innovative techniques, understanding the future landscape of CNC machined parts becomes essential for maintaining competitive edge and operational efficiency.

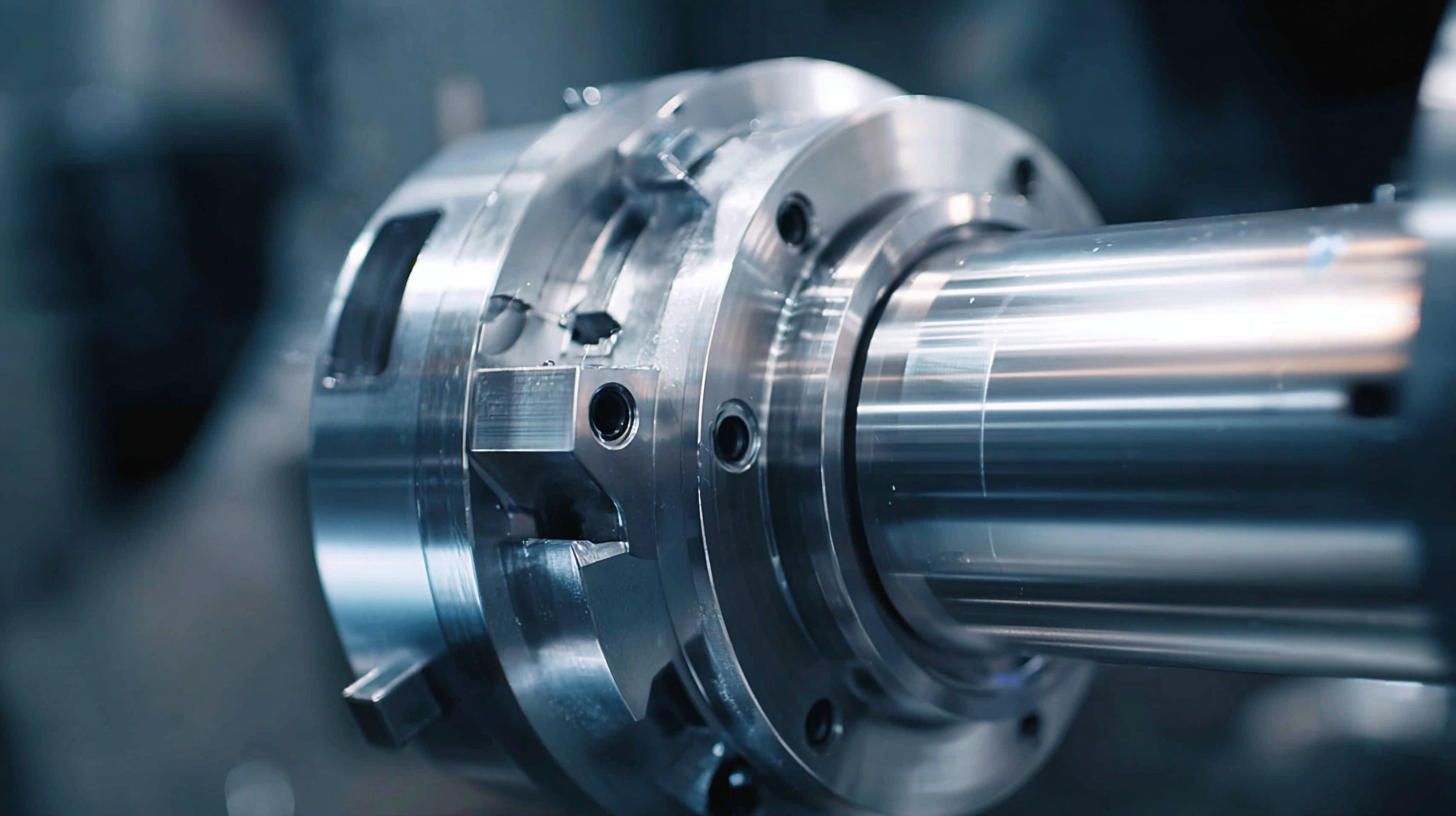

The evolution of CNC machining has increasingly become a cornerstone of modern manufacturing landscapes, driven by technological advancements and the demand for precision. As companies like Craftcloud integrate CNC machining into their advanced manufacturing platforms, they enhance operational efficiency by providing instant quotes and delivery estimates. This not only streamlines the production process but also caters to the growing need for high-quality, precise parts sourced from a global network.

Moreover, the market for CNC machine tools is projected to experience significant growth, with an estimated increase of USD 21.9 billion by 2029. Factors such as the rising demand for high-precision and multi-axis machining centers play a vital role in this expansion. Additionally, Artificial Intelligence (AI) is redefining the CNC machining landscape, revolutionizing the way these tools are programmed and operated. As AI continues to penetrate this space, its influence will likely lead to more innovative manufacturing techniques, ultimately paving the way for a future where CNC machining plays an even more pivotal role in industrial operations.

The future of CNC machined parts is being reshaped by emerging innovative techniques that leverage advanced technologies such as AI, robotics, and additive manufacturing. A recent report indicates that the global CNC machining market is projected to reach $100 billion by 2025, driven by increasing demand for precision and efficiency across various sectors. This transformation is not just limited to traditional machining but extends to rapid prototyping, where sustainable practices are reshaping manufacturing workflows. The shift towards environmentally friendly processes is becoming a competitive advantage, as companies seek to improve their carbon footprint while enhancing production speed and accuracy.

Educational institutions like the University of St. Thomas are pivotal in this transition. Their training programs equip engineers and students with the skills needed to harness these new technologies effectively. Inside the university's machine shop, students witness firsthand the power of modern CNC equipment that utilizes real-time data analytics and adaptive technologies, underscoring a significant shift in manufacturing paradigms. As more businesses invest in cutting-edge technology, such as the $3.25 million recently allocated by a leading contract manufacturer to upgrade their machinery, the evolution of CNC machined parts is poised to redefine industry standards, making them more versatile and sustainable.

The landscape of manufacturing is rapidly evolving, and CNC (Computer Numerical Control) machining stands at the forefront of this transformation. As industries increasingly prioritize sustainability, CNC manufacturing techniques are being refined to minimize waste and energy consumption. By integrating advanced technologies such as AI and IoT, manufacturers are able to optimize CNC processes, resulting in not only reduced environmental impact but also enhanced production efficiency.

Tips for adopting sustainable CNC practices include investing in energy-efficient machinery and utilizing biodegradable cutting fluids. Additionally, recycling waste materials generated during machining can significantly reduce the carbon footprint of operations. It’s essential for companies to consider the entire lifecycle of their products, allowing for greater recyclability and resource recovery.

As manufacturers become more mindful of sustainability, CNC machining is not merely a method of production but a pathway toward more responsible industrial practices. Implementing smart scheduling systems and predictive maintenance can lead to significant gains in efficiency, reducing downtime and ensuring that resources are utilized effectively. By embracing these innovative approaches, the future of CNC manufacturing is not just about making parts, but making them in a way that respects our environment and conserves resources.

The integration of smart technologies in CNC machining processes is transforming the landscape of innovative manufacturing techniques. As the demand for increased efficiency and productivity intensifies, automation has become a vital component in CNC environments. The introduction of smart sensors plays a critical role in this evolution, enabling real-time monitoring and quality assurance throughout the manufacturing process. These advancements allow for closed-loop systems that enhance precision and reduce waste, addressing the need for cost-competitive manufacturing.

Moreover, the market for CNC machines is projected to experience significant growth, driven by the adoption of digital technologies. With a forecasted expansion to over USD 170 billion by 2033, this sector is witnessing a notable shift towards smart manufacturing solutions. Digitalization software is enhancing shopfloor performance, fostering an environment where machine tool users can optimize their operational efficiency. As the UK and global manufacturing sectors embrace these changes, the future of CNC machined parts is undoubtedly intertwined with the rise of smart technologies, paving the way for unprecedented levels of innovation and productivity.

This chart illustrates the projected integration of smart technologies in CNC machining processes over the next five years, showcasing the percentage of manufacturers adopting advanced technologies such as IoT, AI, and automation.

The evolution of CNC machined components is marked by significant challenges and opportunities that fuel innovation in manufacturing techniques. One of the primary challenges is the rapid advancement of technology, which necessitates continuous adaptation and integration of new tools and software. Manufacturers must invest in state-of-the-art machinery and training for their workforce to remain competitive. Additionally, issues related to supply chain disruptions, material shortages, and rising costs can hinder production efficiency and drive companies to rethink their sourcing strategies.

On the other hand, the future of CNC machined parts is rich with opportunities for those willing to embrace change. The rise of Industry 4.0 presents a chance to harness data analytics and automation, allowing for smarter manufacturing processes and reduced waste. Advances in materials, such as lightweight composites and biocompatible substances, open new avenues for product design and application, particularly in industries like aerospace and medical. Furthermore, with the increasing demand for customization, CNC machining is well-positioned to provide flexible solutions that cater to specific client needs, thereby enhancing overall value in production.