+86 180 0293 5268

+86 180 0293 5268

The advent of Industry 4.0 is revolutionizing the manufacturing landscape, significantly impacting the production of Precision Machining Parts. According to a recent report by MarketsandMarkets, the global precision machining market is expected to grow from $80 billion in 2020 to over $120 billion by 2025, driven by advancements in automation, IoT, and data analytics.

As manufacturers increasingly adopt smart technologies, the demand for highly accurate and customized machining components continues to rise. This shift is pushing companies to rethink their operational strategies and embrace digital transformation to enhance productivity and quality. In this blog, we will explore key trends, challenges, and best practices that shape the future of Precision Machining Parts within the Industry 4.0 framework, equipping stakeholders with essential insights and tips to stay competitive in this evolving sector.

In the realm of Industry 4.0, the integration of the Internet of Things (IoT) is fundamentally transforming the landscape of precision machining parts. According to a report from McKinsey, the adoption of IoT technologies can potentially increase productivity by up to 20% in manufacturing industries. The ability to collect real-time data from machines allows manufacturers to monitor performance, predict maintenance needs, and optimize production processes, resulting in enhanced precision and reduced downtime.

Moreover, the global IoT in manufacturing market is projected to reach $530 billion by 2025, as reported by Statista. This staggering growth illustrates the increasing reliance on interconnected devices and sensors to achieve higher quality standards in precision machining. By leveraging IoT solutions, manufacturers are not only able to improve accuracy in part production but also gain insights into operational efficiencies. This data-driven approach fosters a proactive manufacturing environment where adjustments can be made swiftly, thereby maintaining competitive advantages in an ever-evolving industrial landscape.

This chart illustrates the projected growth of precision machining parts in the context of Industry 4.0, highlighting the impact of IoT on productivity and efficiency from 2022 to 2026.

In the era of Industry 4.0, the demand for precision machining parts is being transformed by advancements in materials science. Understanding the properties and capabilities of advanced materials is crucial for manufacturers looking to enhance product performance and reduce production costs. According to a report by MarketsandMarkets, the global advanced materials market is projected to reach $126.2 billion by 2026, growing at a CAGR of 8.2% from 2021. This growth is primarily driven by innovations in nanomaterials, composites, and smart materials, which are increasingly being utilized in precision components.

Advanced materials are enabling the design of lightweight yet highly durable components that can withstand extreme conditions. For instance, titanium alloys have gained popularity in aerospace applications due to their excellent strength-to-weight ratio and corrosion resistance. Additionally, the integration of smart materials, such as shape-memory alloys, is revolutionizing the functionality of precision parts by allowing them to respond to external stimuli. A report from Grand View Research highlights that the smart materials segment alone is expected to see significant growth, with a value estimated at $62.31 billion by 2028. As manufacturers adapt to the challenges presented by Industry 4.0, a focus on advanced materials will be key to driving innovation in precision machining.

The integration of artificial intelligence (AI) and machine learning (ML) into precision machining processes marks a significant evolution in the era of Industry 4.0. AI enhances the precision and efficiency of manufacturing operations by enabling real-time decision-making and process monitoring. Through advanced algorithms, AI systems can analyze vast amounts of data to predict equipment failures, optimize machining parameters, and improve overall production quality. This predictive maintenance approach reduces downtime and operational costs while increasing efficiency.

Moreover, the adoption of explainable artificial intelligence (XAI) is paving the way for greater transparency and trust in AI-driven processes. In additive manufacturing, the integration of ML and XAI provides insights into the decision-making processes of the machines, ensuring that operators and engineers can understand and rectify any issues that arise. This transformative shift seeks not only to enhance the capabilities of traditional machining but also to foster innovation by leveraging smart manufacturing technologies, such as digital twins and edge computing, to fuel market growth and stability.

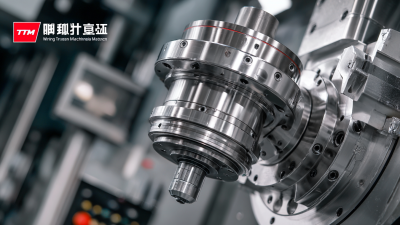

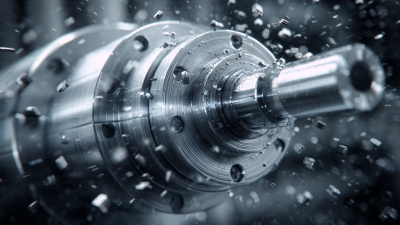

The evolution of precision machining is intricately tied to the advancements in automation and robotics, especially as industries move toward Industry 4.0. Automation is revolutionizing traditional machining processes by enhancing efficiency and precision. With the incorporation of smart technologies, manufacturers can now utilize automated systems that not only streamline workflows but also reduce human error. The use of CNC machines equipped with advanced programming capabilities enables businesses to produce intricate parts with remarkable accuracy and repeatability.

Robotics is another game-changer in the realm of precision machining. Collaborative robots, or cobots, are being employed alongside human workers to handle repetitive tasks, thereby allowing skilled machinists to focus on complex operations that require critical thinking. These robots can operate in various environments, adapting to changes in production needs and ensuring optimal performance. As sensor technology and artificial intelligence continue to advance, the integration of robotics into precision machining will lead to smarter production systems that are capable of self-optimization and predictive maintenance, enhancing overall productivity and reducing downtime.

As industries transition into the era of Industry 4.0, precision machining faces unique challenges that must be addressed for successful adaptation. One of the primary hurdles is the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics into existing machining processes. Manufacturers need to rethink their traditional workflows and invest in smart machinery that can communicate and collaborate in real-time. This shift not only requires financial investment but also a cultural change within organizations toward embracing digital transformation.

Moreover, the skill gap presents another significant challenge. As machining operations become more automated and data-driven, workers must possess new skill sets to manage and interpret data generated by smart systems effectively. Companies need to prioritize workforce development, offering training programs and resources that equip their employees with the necessary expertise. By fostering a culture of continuous learning, organizations can ensure that their teams are prepared to navigate the complexities of Industry 4.0 and leverage precision machining innovations to enhance productivity and competitiveness in the market.

| Challenges | Impact | Proposed Solutions | Technologies Involved |

|---|---|---|---|

| Integration of Smart Technologies | Increased operational complexity | Invest in training and workforce development | IoT, AI, Machine Learning |

| Data Management and Security | Risk of data breaches | Implement strong cybersecurity measures | Cloud Computing, Cybersecurity Solutions |

| Adaptability to New Technologies | Slower production transitions | Establish pilot projects for gradual adoptions | Additive Manufacturing, CAD/CAM Software |

| Supply Chain Disruptions | Delays in production | Diversify supply sources | Blockchain, Advanced Analytics |

| Regulatory Compliance | Increased compliance costs | Regular audits and compliance training | Regulatory Reporting Software |