+86 180 0293 5268

+86 180 0293 5268

In the world of High Precision Casting, achieving success requires more than just technical skills. It demands a deep understanding of materials, processes, and market demands. As John Smith, a renowned expert in the casting industry, once said, "Precision is not just a goal; it is the foundation of excellence in casting." This philosophy serves as a guiding principle for many professionals.

High Precision Casting involves meticulous attention to detail. Every step, from design to final finish, must be executed flawlessly. Yet, challenges often arise. Flaws in casting may develop due to poor material selection or inadequate process control. Reflecting on these mistakes leads to improvement.

The journey to high precision is not easy. It requires innovation, patience, and a willingness to learn from failures. Embracing the imperfections and seeking solutions can ultimately lead to mastery in High Precision Casting. Therefore, let's explore ten essential tips that can pave the way for casting success.

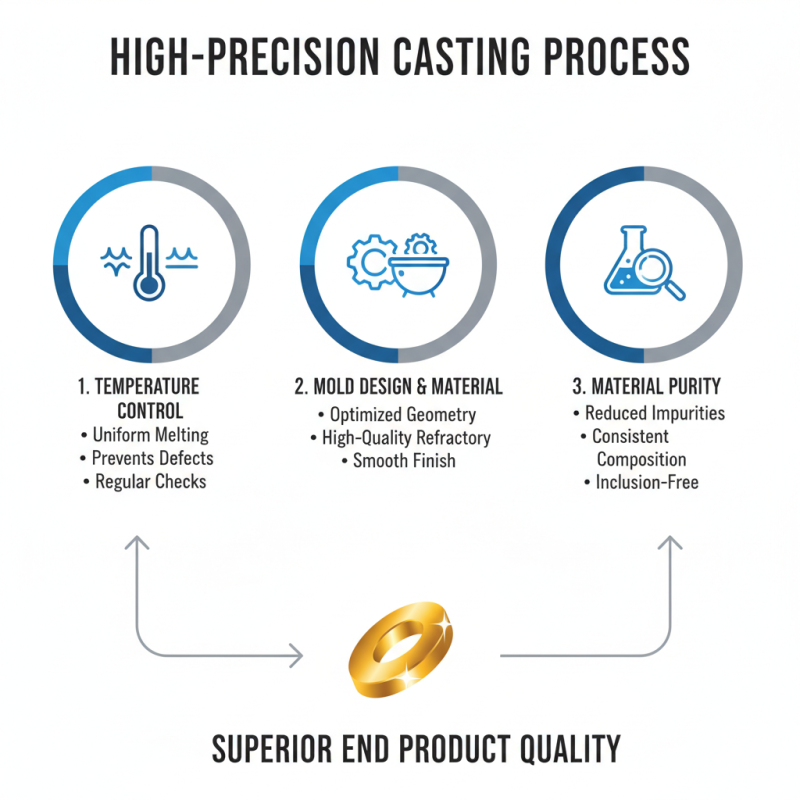

Achieving high precision in casting processes involves several key factors that can significantly influence the end product's quality. Temperature control is crucial. Maintaining the right temperature ensures uniform melting of metals. A slight variation can lead to defects. It is essential to conduct regular temperature checks.

The molding material matters too. Choosing the right materials helps achieve the desired precision. Pay attention to the moisture content in sands. Too much moisture can lead to inconsistent casting results. Remember, the mold’s surface finish will also impact the final product. A smoother surface often results in better detail replication.

Regular maintenance of equipment is vital for success. Old or poorly maintained machinery can introduce errors in the casting. Schedule regular inspections to catch issues early. Providing adequate training for staff is equally important. Knowledgeable workers can identify problems that may arise during production. These factors collectively contribute to high precision casting. Even minor oversights can lead to major flaws.

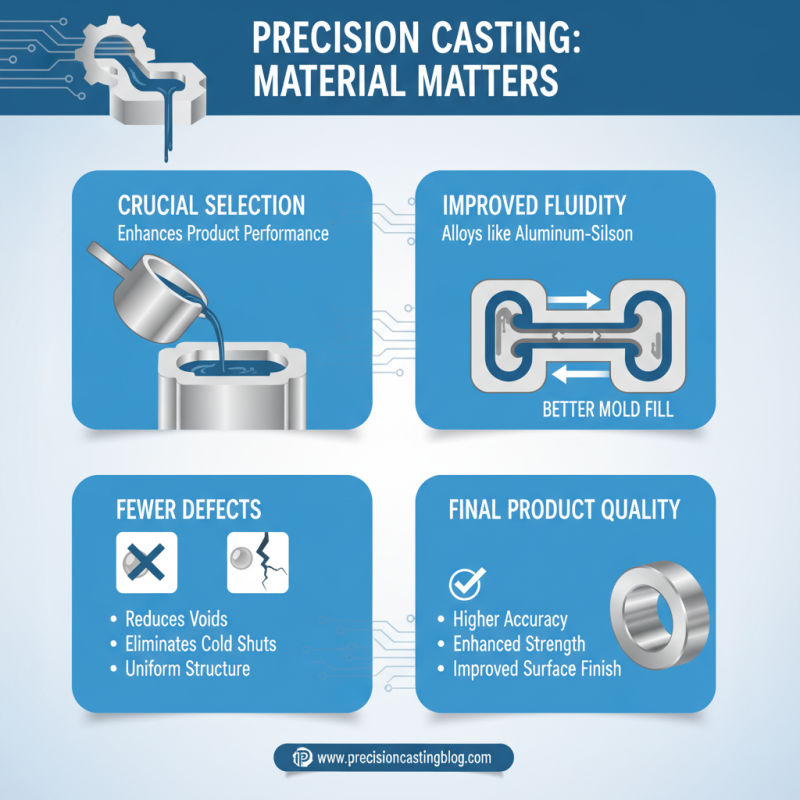

Material selection is crucial for achieving high precision in casting. The right materials can significantly enhance the overall performance of the final product. For instance, using alloys that have good fluidity can improve mold filling. This leads to fewer defects like voids or cold shuts.

However, the selection process is not always straightforward. Each material has its pros and cons. For example, while aluminum offers lightweight benefits, it may not withstand high temperatures as well as steel. This requires careful consideration based on the application's demands. Even experienced professionals may overlook the subtleties that come with different materials.

Additionally, recycling materials can save costs but can also introduce variability in properties. For high precision parts, this variability can be problematic. It's essential to regularly assess the composition of recycled materials. Inflation and market changes sometimes push for materials that may not meet optimal standards. Rethinking material choices during every project phase can lead to surprising insights and improvements along the way.

Mold design plays a crucial role in precision casting. Each detail in the mold influences the final product. A well-designed mold minimizes defects. However, achieving this perfection can be challenging. Small errors can lead to big issues. Every angle and curve needs consideration. Using advanced design software can help visualize these aspects. Yet, even with technology, mistakes can slip through.

Effective mold design requires collaboration. Engineers and designers must communicate seamlessly. Each team member brings a unique perspective. Failure to discuss could result in costly revisions. Testing the mold with prototypes is essential. This phase reveals potential flaws before mass production. Customers often expect high precision, amplifying the pressure on teams. The delicate balance between cost and quality remains a constant challenge. Adjusting designs for budget constraints is not always straightforward. Each decision has long-term implications.

Mold maintenance also demands attention. Regular checks ensure the molds remain functional. A neglected mold can produce subpar products. Awareness of wear and tear is vital. Understanding when to replace components can save time and resources. Continuous learning and adaptation are necessary for success. Even seasoned professionals can overlook aspects of mold design. Keeping an open mind to feedback fosters improvement. This ongoing process is essential for refining precision casting practices.

High precision casting relies heavily on controlling temperature and cooling rates. The relationship between cooling speed and final part quality is crucial. Studies show that a cooling rate of 5-10 degrees Celsius per minute can reduce defects in castings by up to 30%. Proper control methods help achieve uniform microstructures. Uneven cooling can lead to warping and internal stresses in the final product.

In many operations, achieving consistent temperature control is a challenge. It’s essential to monitor molten metal temperatures closely. Fluctuations can result in poor casting properties. Implementation of modern temperature sensors can improve accuracy. However, not all factories utilize advanced tech. Some still rely on outdated methods. This can hinder their competitiveness in the market.

Cooling methods also play a vital role. Air cooling may be easier but often leads to slower solidification rates. Water or oil quenching can produce quicker cooling but might introduce risks of cracking. Careful experimentation is needed to find the right balance. Manufacturers should analyze their cooling strategies regularly. What works today might not suit future demands. Adjustments will be necessary as needs evolve in this fast-paced industry.

Precision casting is critical in industries like aerospace and automotive. According to a report by the American Foundry Society, precision cast parts account for about 15% of all castings produced. Quality assurance is vital in this process. Implementing rigorous testing protocols ensures that each component meets stringent specifications.

Visual inspections, dimensional checks, and material testing are common techniques. A study from the Casting Industry Research Association highlighted that 30% of casting defects arise from poor quality control measures. This underscores the need for effective methodologies. Regular audits can help identify gaps.

However, even the best techniques have limitations. Flaws may slip through, causing costly rework. Continuous improvement initiatives focus on reducing such defects. Investing in technology can enhance precision. Data analysis tools can predict potential failures before they occur.