+86 180 0293 5268

+86 180 0293 5268

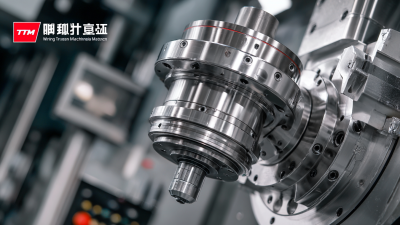

In the rapidly evolving landscape of manufacturing, Precision Metal Machining has emerged as a critical component driving industrial efficiency and quality. This innovative trend is reshaping the way industries approach production, offering enhanced accuracy and reduced waste, which ultimately lead to cost savings and improved product performance. As businesses strive to remain competitive in a global market, understanding how to leverage advancements in Precision Metal Machining has become essential.

This article will delve into various innovative techniques and technologies that are transforming Precision Metal Machining. By exploring methodologies such as automation, advanced tooling, and real-time data analytics, we will illustrate how these trends not only increase operational efficiency but also ensure superior quality in end products. Moreover, we will discuss the practical applications of these innovations across various sectors, providing insights on how industries can adapt and thrive in the new age of manufacturing. Emphasizing the importance of continuous improvement, this guide aims to equip readers with the knowledge necessary to navigate the complexities of Precision Metal Machining and harness its full potential for their operational success.

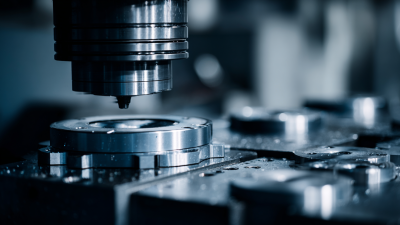

Precision metal machining is essential for achieving high levels of accuracy and quality in various industries. Key techniques such as CNC machining, which utilizes computer-controlled tools for cutting and shaping metal, have revolutionized the manufacturing landscape. This process allows for intricate designs and repeatable precision, making it indispensable in sectors like aerospace, automotive, and medical devices. Understanding the various processes—such as turning, milling, and grinding—is crucial for optimizing production workflows and meeting stringent quality standards.

Tip: When selecting a machining technique, consider the specific requirements of your project, including material type, desired tolerances, and production volume. Choosing the right method can significantly impact efficiency and end product quality.

Another important aspect is the integration of advanced technologies like automation and robotics. These innovations not only enhance speed but also reduce human error, resulting in improved outcomes. Additionally, implementing real-time monitoring systems ensures that any deviations from quality standards can be immediately addressed, further solidifying the role of precision machining in modern manufacturing.

Tip: Invest in training for your workforce to adapt to new technologies in precision machining. A well-trained team can leverage these advancements to boost both productivity and quality across your projects.

In the ever-evolving field of precision metal machining, the integration of automation has become a pivotal factor in enhancing machining accuracy and overall efficiency. According to a report by MarketsandMarkets, the global automation market in the manufacturing sector is projected to reach $200 billion by 2025, driven by the increasing demand for high-quality and precise machining parts. Automation technologies such as CNC machines, robotic arms, and AI-powered monitoring systems are significantly reducing human error and variability in production processes, ensuring that the finished components meet stringent quality standards.

Moreover, a study conducted by McKinsey highlights that companies that have adopted advanced automation in their machining operations can achieve productivity gains of up to 30%. Automated systems not only optimize machining cycles but also facilitate real-time data analysis, which allows for immediate adjustments and predictive maintenance. This level of precision not only minimizes waste but also reduces downtime, aligning with the industry's broader trend towards lean manufacturing practices. As the demand for high-quality, precise components continues to grow, the role of automation in precision metal machining will only become more critical, shaping the future landscape of the industry.

Advanced materials are transforming the landscape of precision metal machining, enabling manufacturers to achieve higher efficiency and superior quality. The utilization of materials such as titanium alloys, carbide, and advanced polymers is becoming increasingly common. These materials not only enhance the durability of cutting tools but also allow for greater precision in machining processes. By integrating these innovative materials into their operations, manufacturers can significantly reduce wear and tear, resulting in lower costs and increased production speeds.

Tips: When considering new materials for your machining operations, conduct thorough research on their properties and how they interact with existing machinery. Understanding the specific strengths of materials, such as heat resistance and toughness, can lead to better machining outcomes.

Additionally, adopting advanced materials can improve the overall sustainability of machining operations. Many modern materials are designed to be more environmentally friendly and can lead to less waste during the machining process. This shift not only benefits the environment but can also enhance a company's reputation and appeal to eco-conscious customers.

Tips: Evaluate the lifecycle impact of materials before making a switch. Selecting materials that offer better recyclability or lower energy consumption during production can contribute to a more sustainable manufacturing approach.

The integration of Industry 4.0 technologies in precision metal machining has become a game-changer for enhancing operational efficiency and quality. Advanced solutions like digital twins are redefining manufacturing processes, enabling predictive maintenance and real-time monitoring. As per recent reports, the global multi-axis machining centers market is projected to grow from approximately USD 79.36 billion in 2024 to USD 134.92 billion by 2033, illustrating a significant demand for advanced machining technologies.

Tips: To stay ahead in this evolving landscape, consider investing in digital twin technology to streamline operations and reduce downtime. Emphasizing predictive analytics can also empower businesses to anticipate issues before they arise, thus minimizing disruptions.

Additionally, the CNC machine market is expected to reach USD 170.4 billion by 2033, growing at a CAGR of 9.80%. This surge emphasizes the importance of smart manufacturing technologies in improving productivity across various industries. Leveraging AI and robotics alongside CNC machines can drive a transformation in production capabilities, pushing the boundaries of precision and efficiency in metal machining.

Tips: Explore machine learning algorithms to optimize your machining processes continuously. Adopting such innovations can ensure your operations not only keep pace with but also lead in an increasingly competitive market.

| Trend | Description | Impact on Efficiency | Impact on Quality | Industry 4.0 Integration |

|---|---|---|---|---|

| Automated Machining Processes | Utilizing AI and robotics to automate precision machining tasks. | Reduces labor costs and increases production speed. | Enhances consistency in product quality. | High compatibility with smart factory setups. |

| IoT Integration | Connecting machines and tools to the Internet for real-time monitoring. | Enables predictive maintenance, reducing downtime. | Improves quality control through data analytics. | Key element in Industry 4.0 frameworks. |

| Additive Manufacturing | Integrating 3D printing technologies for complex part production. | Reduces material waste and allows for rapid prototyping. | Enables custom designs with higher precision. | Supports digital production lines for flexibility. |

| Advanced Materials | Using new alloys and composites to enhance performance. | Increases machining efficiency and tool lifespan. | Enhances part durability and reliability. | Facilitates smarter material choices in production. |

| Data-Driven Decision Making | Leveraging big data analytics for operational insights. | Optimizes production schedules and resource allocation. | Improves overall product quality through data feedback. | Aligns with Industry 4.0 principles of smart analytics. |

The integration of augmented reality (AR) into quality control processes is revolutionizing precision metal machining, significantly enhancing product quality and operational efficiency. By offering real-time visual guidance, AR minimizes human error and accelerates problem-solving, streamlining workflows in machining environments. According to recent studies, manufacturers that implement AR technologies can reduce inspection times by up to 30%, leading to faster production cycles and improved consistency in output quality.

Furthermore, the adoption of the Quality 4.0 framework, particularly within the automotive sector, exemplifies how machine learning (ML) enhances quality management practices. By leveraging data analytics, companies can monitor processes in real-time, allowing for predictive maintenance and reducing defects in machined components. Research indicates that businesses utilizing ML within their quality processes experience a 20% reduction in product recalls and warranty claims, underscoring the critical role of technology in fostering superior machined products and increasing overall industry efficiency.

This chart illustrates the adoption rates of various innovative trends in precision metal machining. The data reflects the increasing emphasis on automation, quality control measures, material innovations, process optimization, and data analytics, showcasing how industries are striving for enhanced efficiency and product quality.