+86 180 0293 5268

+86 180 0293 5268

Investment casting aluminum has gained traction in various industries for its unique advantages. John Smith, a recognized expert in metal casting, emphasizes, "Investment casting aluminum offers precision and strength that few processes can match." This statement highlights the growing preference for this method in engineering projects.

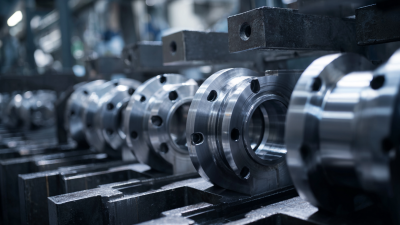

The process allows for complex geometries, which are often needed in aerospace and automotive sectors. With investment casting aluminum, you can achieve intricate designs with fewer defects. However, this technique comes with challenges. For example, the initial costs can be higher compared to traditional methods. Many businesses hesitate to adopt it without thorough analysis.

Despite these obstacles, the benefits often outweigh the drawbacks. Industries are seeing improved durability and performance in their products. Yet, it's crucial to reflect on your specific project needs. Are you ready to invest in investment casting aluminum? Understanding both sides is essential for making an informed decision.

Investment casting aluminum offers remarkable benefits in precision engineering. This process allows for intricate designs with high dimensional accuracy. It creates components with smooth surface finishes, reducing the need for extensive post-processing. Precision is key in industries like aerospace and automotive. These sectors demand uniformity and reliability in their parts.

One striking advantage is the ability to produce complex shapes. Traditional methods struggle with intricate geometries. But investment casting shines here, delivering parts that would be nearly impossible to machine. This flexibility can lead to reduced weight, which is crucial in many applications. However, achieving perfection is not always guaranteed. Controlling the casting process requires careful monitoring.

Moreover, investment casting aluminum can be cost-effective over time. While the initial setup may seem costly, the savings accumulate with larger production runs. Yet, one must consider the material waste during the process. Despite its many advantages, not every project may benefit from this method. It's essential to evaluate if investment casting aligns with specific project goals or requirements.

| Dimension | Description | Benefits |

|---|---|---|

| Weight | Lightweight material ideal for automotive and aerospace | Reduces overall vehicle weight, improving fuel efficiency |

| Precision | High accuracy in dimensions and complex geometries | Minimizes machining requirements and ensures better fits |

| Surface Finish | Excellent surface finish achievable without extensive post-processing | Provides a better aesthetic and functional surface for components |

| Complex Shapes | Ability to create intricate designs and detailed features | Allows for innovative designs that would be difficult with other methods |

| Material Properties | Good strength-to-weight ratio and corrosion resistance | Enhances durability and longevity of components in various environments |

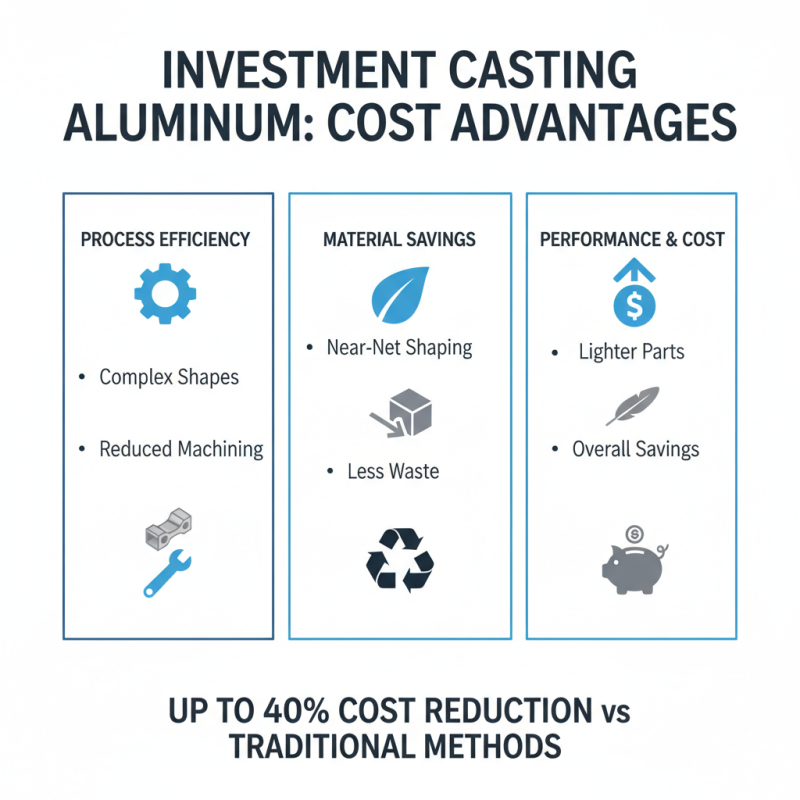

Investment casting aluminum offers significant cost advantages compared to traditional manufacturing methods. This technique allows for complex shapes and finer details, reducing the need for additional machining. It minimizes waste by using a near-net shape process. The intricate designs possible with investment casting can also make parts lighter, saving on material costs.

Traditional methods often involve longer production times and higher labor costs. Many manufacturers face difficulties when producing intricate parts. Investment casting can streamline the process. However, the initial setup cost can be higher. This could deter some businesses, especially small ones. They might fear the risk without guaranteed returns.

While investment casting may hold promise, it also requires careful consideration. Analyzing design feasibility is crucial. Some complex designs can lead to increased costs if not planned properly. Each project should thoroughly evaluate the balance between complexity and cost. Choosing the right method is essential for project success.

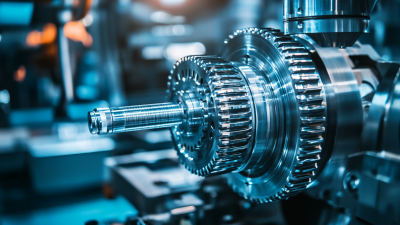

When considering investment casting aluminum, its superior surface finish stands out. This process allows for intricate designs. The smooth finish reduces the need for extensive machining. Small details are preserved, enhancing the overall appearance. Many industries benefit from this capability.

Tolerance is another crucial factor. Aluminum castings can achieve remarkable precision. This precision is vital for parts that must fit together perfectly. Misalignment issues can arise from minor discrepancies. Ensuring accuracy in casting minimizes these headaches down the line.

However, challenges do exist. The casting process may introduce small imperfections. These can affect the final product's performance. Careful inspection and tolerance checks are essential. Adjusting designs may be necessary to account for these variables. Investing time in refinement pays off in the end.

Investment casting aluminum is an excellent option for various projects. One of its main benefits lies in the environmental advantages of using recycled aluminum. This process significantly reduces the carbon footprint. By utilizing recycled materials, companies can help conserve natural resources and limit waste. Aluminum can be recycled multiple times without losing quality. This makes it a sustainable choice in manufacturing.

When considering investment casting, remember that using recycled aluminum decreases energy consumption. It takes only 5% of the energy required to produce new aluminum. This energy efficiency translates into lower production costs and a less harmful impact on the planet. Choosing recycled aluminum could elevate your project’s marketability as eco-conscious consumers favor sustainable practices.

Tips for maximizing the benefits of recycled aluminum: Always check the source of your materials. Ensure they come from reputable channels. Stay informed about the recycling process to better understand how it impacts quality. Consider trial runs with different alloys to find the best fit for your project. While recycled aluminum is typically reliable, some adjustments may be needed for optimal performance.

The demand for aluminum investment castings is growing rapidly in various industries. This growth is driven by aluminum’s lightweight properties and excellent strength-to-weight ratio. Manufacturers are recognizing the benefits of using aluminum in automotive, aerospace, and electronics. These sectors value reducing weight without sacrificing performance.

However, there are challenges to consider. The investment casting process can be complex. Skilled labor is needed for precision and quality. Additionally, fluctuations in aluminum prices can impact project budgets. Companies must stay informed about market trends to navigate these issues effectively. Understanding client needs and preferences is crucial for successful outcomes.

Emerging technologies are reshaping the investment casting landscape. Innovations in 3D printing are making it possible to create complex geometries. This opens new doors for product design and functionality. Yet, companies need to invest time and resources to integrate these advancements effectively. Balancing innovation with quality is not always easy, but it is essential for long-term success.