+86 180 0293 5268

+86 180 0293 5268

Investment casting, also known as the lost wax process, has established itself as a crucial method for manufacturing precision metal parts across various industries, including aerospace, automotive, and medical. According to a recent report by the Research and Markets Group, the global investment casting market is projected to reach $22.2 billion by 2027, reflecting a compound annual growth rate (CAGR) of 5.2%. This growth underscores the increasing demand for high-quality components that are both lightweight and durable, aligning with the stringent requirements of modern engineering applications.

Industry expert Dr. John Smith, a leading authority in the field of metal casting, emphasizes the importance of this process by stating, "The Investment Casting Lost Wax method allows for the creation of intricately detailed parts that maintain tight tolerances, which is essential in achieving the high performance required in today's advanced technological applications." As industries continue to push the boundaries of innovation, the investment casting lost wax process remains vital for ensuring precision and reliability in manufacturing, making it indispensable for the future of engineering and production.

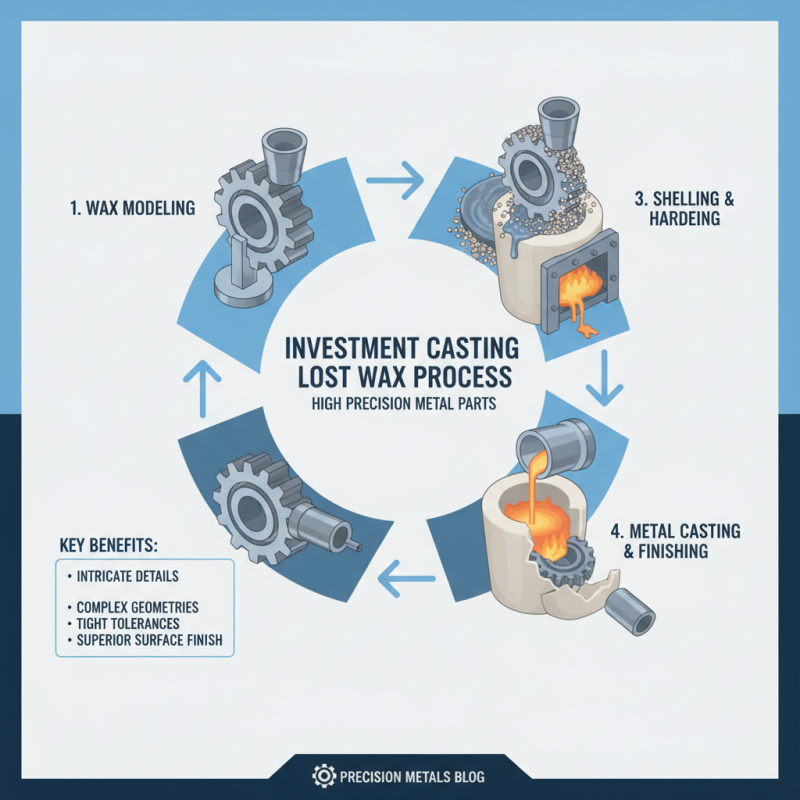

The investment casting lost wax process is renowned for its ability to create intricately detailed metal parts that require high precision. This technique begins with a wax model, which is coated in a ceramic shell that hardens upon heating. Once the shell is formed, the wax is melted away, leaving a cavity that replicates the original model’s intricate details. This capability makes the process ideal for complex geometries and tight tolerances that traditional metalworking methods often struggle to achieve.

One of the key characteristics of the lost wax process is its versatility in material usage. It allows for a wide range of metals, including aluminum, stainless steel, and titanium, to be cast with exceptional quality. Additionally, the process minimizes waste, as it produces near-net-shape parts that require little to no machining. The resulting components not only demonstrate superior surface finishes but also exhibit enhanced mechanical properties, making the investment casting lost wax process vital for industries where reliability and precision are paramount.

The investment casting lost wax process is highly regarded for its ability to produce precision metal parts that meet the stringent requirements of various industries. This technique allows for intricate designs and complex geometries that are often unattainable with other manufacturing methods. As a result, industries such as aerospace, automotive, and medical device manufacturing benefit immensely from the high level of accuracy and quality that investment casting provides.

One of the key benefits of investment casting is the reduction of material waste. By creating metal parts with a high degree of precision, manufacturers can optimize their material usage, leading to cost savings and more sustainable practices. Additionally, the smooth surface finish achieved through this process often reduces or eliminates the need for extensive machining, further minimizing production time and expenses.

**Tip:** When considering investment casting for precision metal parts, it's important to work closely with your foundry to ensure that the design aligns with the casting capabilities. This collaboration can help avoid costly redesigns and ensure an optimal outcome. Additionally, always consider the properties of the material being used to maximize performance and durability in the final product.

| Dimension | Benefits | Applications |

|---|---|---|

| Tolerances < 0.005 inches | High precision and reduced machining costs | Aerospace components |

| Complex geometries | Ability to create intricate designs | Medical devices |

| Material diversity | Wide range of materials available | Automotive parts |

| Surface finish < Ra 16 | Superior surface quality | Oil and gas applications |

Investment casting, particularly the lost wax process, plays a crucial role in the aerospace and automotive industries, where precision and reliability are paramount. In aerospace, components such as turbine blades and structural parts require exceptionally tight tolerances and intricate geometries that are often impossible to achieve through traditional manufacturing methods. The lost wax process allows engineers to produce complex shapes with high dimensional accuracy, enabling lighter and more efficient designs that enhance overall aircraft performance.

In the automotive sector, investment casting provides significant advantages in producing engine components, gear housings, and other crucial parts. The ability to create intricate designs not only reduces the weight of the components but also improves fuel efficiency and performance. Moreover, the durability and strength of investment cast parts ensure that they can withstand the rigorous demands of automotive applications, leading to longer-lasting vehicles.

As industries push for higher performance and sustainability, the lost wax process in investment casting remains essential for developing cutting-edge metal parts that meet modern engineering challenges.

Investment casting, particularly the lost wax process, stands out in the landscape of metal fabrication methods due to its unparalleled precision and versatility. Unlike traditional methods such as machining or forging, investment casting allows for the creation of intricate designs and complex geometries that other techniques struggle to achieve. The use of a wax pattern, which is melted away during the casting process, enables manufacturers to produce parts with smooth surface finishes and tight tolerances. This is especially beneficial in industries like aerospace and medical, where precision is paramount.

In comparison, machining involves removing material from a solid block, which can introduce limitations in design complexity and surface finishes. While forging is excellent for producing strong parts, it often requires additional processes to achieve desired shapes and finishes, leading to increased time and cost. Investment casting offers a more streamlined approach, as it combines molding and finishing into a single process, significantly reducing lead times. Additionally, this method is highly adaptable to various materials, making it a preferred choice for manufacturers seeking efficiency without compromising quality.

The investment casting process, particularly the lost wax method, is increasingly significant in the production of precision metal parts due to evolving technological advancements and material innovations. Recent insights into various industries reveal a push towards enhanced manufacturing techniques that ensure higher quality and precision. For instance, the aerospace forging industry has identified several misconceptions that hinder the adoption of advanced practices, indicating a broader need for education and technological integration across sectors.

Future trends in investment casting technology suggest that emphasis will be placed on innovative materials and smarter manufacturing processes. With advancements in AI and automation, the industry is poised to enhance the efficiency of the casting process, minimizing defects and optimizing material use. As industries shift towards more sustainable practices, materials that offer superior performance while being environmentally friendly will likely dominate, reshaping investment casting methodologies and expanding its application in complex parts requiring precision engineering.