+86 180 0293 5268

+86 180 0293 5268

Investment casting steel has emerged as a vital process in modern manufacturing, offering precision and versatility unmatched by traditional methods. According to a report by the American Foundry Society, the global investment casting market is expected to reach USD 25 billion by 2026, driven largely by advancements in material science and increasing demand in sectors such as aerospace, automotive, and medical devices. This comprehensive guide aims to unlock the myriad benefits of investment casting steel, highlighting its ability to produce complex geometries with minimal waste and exceptional surface finishes. With the steel casting industry projected to grow at a CAGR of 6.0%, understanding the nuances of this manufacturing technique becomes essential for modern manufacturers seeking to enhance productivity and maintain competitive advantage. By leveraging the unique properties of investment casting steel, businesses can innovate and deliver high-quality products that meet the evolving needs of their markets.

Investment casting, also known as lost-wax casting, is a precision manufacturing process that allows for the production of complex steel components with exceptional accuracy. According to a report by the 'American Foundry Society', the investment casting market for steel is projected to grow at a CAGR of 5.6% from 2020 to 2025. This growth is largely driven by the increasing demand for lightweight and durable components across various industries, including aerospace, automotive, and healthcare. The high dimensional accuracy and ability to create intricate geometries make investment casting particularly advantageous for manufacturers looking to optimize their production methods.

Understanding the fundamentals of investment casting steel can significantly enhance a manufacturer's operational efficiency. The process begins with the creation of a wax model, which is coated in a ceramic shell. Once the shell is hardened, the wax is melted away, leaving a precise mold for steel pouring. The 'World Steel Association' asserts that this method reduces waste and energy consumption, leading to more sustainable manufacturing practices. Furthermore, investment casting allows for reduced machining time, as components often require minimal finishing, thereby aligning with the modern manufacturer's goal of achieving cost-effectiveness and improved production timelines.

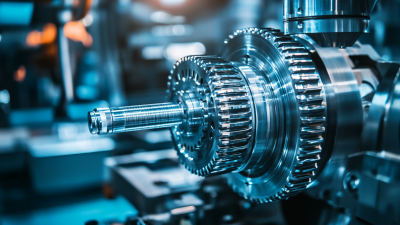

Investment casting steel has increasingly become a preferred method for modern manufacturers, offering distinct advantages over traditional casting techniques. One of the primary benefits is the ability to create highly intricate and complex geometries with superior dimensional accuracy. This precision reduces the need for extensive machining and finishing processes, ultimately saving time and costs. As highlighted at the recent Aluminum Industry Conference, advances in technology, such as 3D printing, further enhance the investment casting framework, enabling manufacturers to produce sophisticated patterns more efficiently.

Moreover, investment casting steel exhibits excellent mechanical properties, making it suitable for a wide range of applications across various industries. The strength-to-weight ratio of investment cast components is often superior to those produced by conventional methods, allowing for lightweight designs that do not compromise performance. These advantages contribute to the overall appeal of investment casting steel, positioning it as a vital choice for forward-thinking manufacturers aiming to embrace innovation while meeting the demanding needs of today’s market.

Investment casting, also known as precision casting, offers modern manufacturers an effective way to produce complex metal components with high accuracy. The investment casting process involves creating a wax pattern of the desired part, covering it with a ceramic shell, and then melting the wax away to form a mold. This method is particularly advantageous for producing intricate designs that would be challenging to achieve with traditional casting techniques. According to industry reports, investment casting can achieve tolerances of +/- 0.5% and eliminate the need for extensive machining, resulting in significant cost savings and reduced lead times.

A step-by-step approach to the investment casting process begins with the creation of a wax model, followed by mold assembly, shell building, and the casting phase. Following casting, parts undergo various finishing processes to meet stringent quality standards. Recent studies indicate that the global investment casting market is expected to grow by over 5% annually from 2023 to 2028, highlighting the increasing demand for this technology in sectors such as aerospace, automotive, and medical devices. As manufacturers seek to optimize their production methods, investment casting stands out for its sustainability and ability to utilize a range of alloy materials effectively, addressing both performance and environmental concerns.

| Process Step | Description | Materials | Advantages |

|---|---|---|---|

| Pattern Creation | Creating a wax or resin pattern that replicates the final product. | Wax, Resin | High precision and intricate designs. |

| Shell Building | Coating the pattern with a ceramic material to form a shell. | Ceramic, Silica Sand | Temperature resistance and dimensional accuracy. |

| Wax Removal | Heating the shell to melt and remove the wax pattern. | N/A | Clean removal leaves a precise mold. |

| Metal Pouring | Pouring molten metal into the mold to create the final form. | Steel, Iron | Versatility with different metals and alloys. |

| Shell Breaking | Breaking away the ceramic shell to reveal the cast metal. | N/A | Efficiency in production with minimal waste. |

| Finishing | Removing any imperfections and finalizing the dimensions. | Grinding tools, Polishing equipment | Enhanced surface finish and accuracy. |

When it comes to

investment casting steel, choosing the right materials is essential for achieving optimal results. Steel used in investment casting must possess specific properties to ensure the durability and integrity of the final product. Manufacturers often prioritize materials that offer excellent mechanical strength, resistance to corrosion, and high thermal stability. Furthermore, opting for non-toxic alloys can enhance safety during the casting process and in the end-use applications, making them favorable for modern, health-conscious manufacturers.

When it comes to

investment casting steel, choosing the right materials is essential for achieving optimal results. Steel used in investment casting must possess specific properties to ensure the durability and integrity of the final product. Manufacturers often prioritize materials that offer excellent mechanical strength, resistance to corrosion, and high thermal stability. Furthermore, opting for non-toxic alloys can enhance safety during the casting process and in the end-use applications, making them favorable for modern, health-conscious manufacturers.

Among the best materials for effective investment casting steel,

stainless steel is a standout choice due to its well-rounded performance and availability in various grades. Additionally, PFAS-free ceramic materials are becoming increasingly popular, as they not only maintain high performance but also align with sustainable practices. These materials have been extensively tested for safety and durability, meeting the rigorous demands of both industrial applications and culinary needs.

By focusing on superior material selection, manufacturers can unlock the full potential of investment casting steel, ultimately resulting in high-quality products that cater to the evolving market.

Investment casting steel has become a pivotal method for manufacturers aiming to achieve high precision and complex geometries. As the industry evolves, quality control in steel production during the investment casting process is critical. Recent data indicates that proper quality management can lead to a reduction in defect rates by up to 30%. Implementing best practices such as real-time monitoring and automated inspections not only ensures consistent product quality but also enhances operational efficiency.

Technological advancements, particularly in automation and data analytics, are transforming the landscape of investment casting. According to a market report, the adoption of smart manufacturing techniques is projected to increase productivity by 20% over the next five years. These innovations facilitate better resource management, which is essential in meeting sustainability goals. Manufacturers are now integrating environmentally friendly practices within their production lines, aligning with global initiatives towards greener manufacturing. As market demands shift towards sustainable solutions, investment casting steel stands at the forefront, offering both quality and eco-friendliness to modern manufacturers.