+86 180 0293 5268

+86 180 0293 5268

Lost Wax Investment Casting has gained immense popularity in the manufacturing sector. This technique allows for intricate designs and precise details. Many industries rely on it, from aerospace to jewelry making. The process involves creating a wax pattern, which is then coated with a ceramic shell. Once heated, the wax melts away, leaving a cavity.

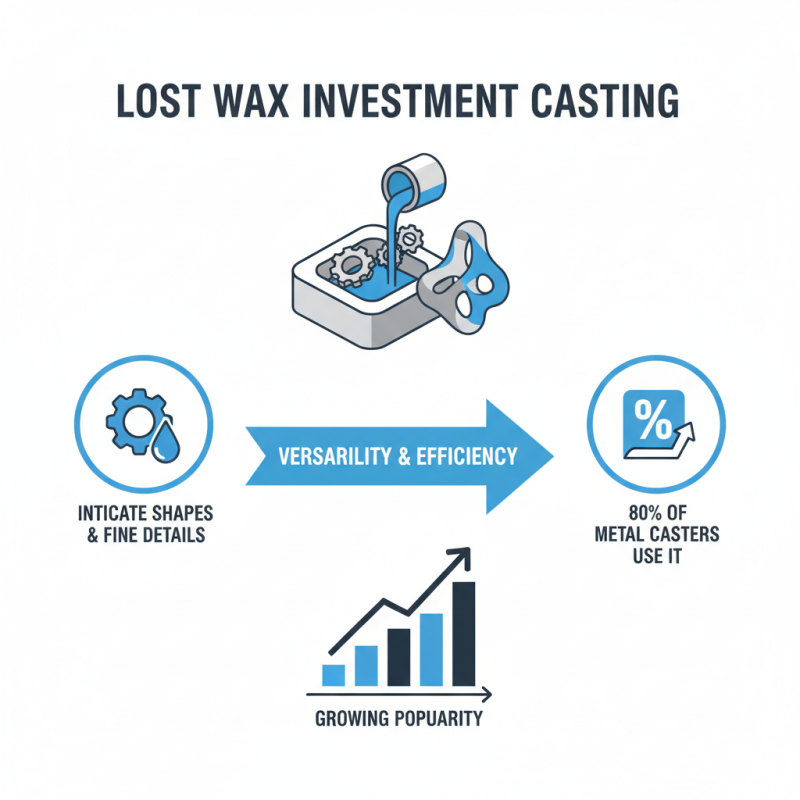

Manufacturers appreciate Lost Wax Investment Casting for its versatility. It can produce complex components that would be difficult to fabricate otherwise. The smooth surface finish reduces the need for extensive machining. Despite its numerous advantages, there are challenges. The initial setup costs can be high, and the process requires skilled craftsmanship.

Moreover, not every material is suitable for this casting method. It’s essential to consider these factors to avoid potential pitfalls. Balancing quality and cost is crucial in the decision-making process. Lost Wax Investment Casting remains a powerful tool, yet it demands careful reflection on its limitations.

Lost wax investment casting has become a go-to method in manufacturing. This process allows for intricate shapes and fine details. According to industry reports, around 80% of metal casters utilize some form of investment casting. This popularity stems from its versatility and efficiency.

The process begins with a wax pattern. This pattern is coated in ceramic material, creating a mold. Once the mold is hardened, the wax is melted away, leaving a precise cavity. According to data, this method can produce parts with tolerances as tight as ±0.1mm. It is ideal for small to medium production runs. However, its setup costs can be high. This makes it less suitable for very large or low-volume orders.

**Tip:** Always evaluate the complexity of your part before opting for lost wax. If your design is simple, other methods might be more cost-effective.

Wax patterns can also present challenges. They require careful handling to prevent damage. The melting process generates waste, contributing to environmental concerns. Efforts are underway to recycle materials in this industry.

**Tip:** Partnering with experienced professionals can mitigate risks. Consider the environmental impact of your chosen methods. This can strengthen your brand and appeal to eco-conscious clients.

Lost Wax Investment Casting is widely adopted across several industries. Aerospace, automotive, and medical sectors are prime examples. According to industry reports, the global investment casting market is projected to reach $20 billion by 2025. This growth is driven by the need for precision and reduction of production costs.

In the aerospace sector, components require high strength and reliability. Investment casting allows for intricate designs with minimal waste. Reports indicate that about 80% of aerospace components can benefit from this method. The automotive industry also leverages this technique for producing complex parts, enabling lighter and more fuel-efficient vehicles. It's noted that investment cast parts can reduce weight by as much as 15% compared to traditional methods.

Medical devices are another area where lost wax casting shines. Components like implants and surgical tools require exact specifications. Investment casting ensures high accuracy, making it vital for critical applications. However, the method isn't without challenges. The process can be time-consuming, and achieving the desired surface finish often demands extra processing. Continuous advancements are needed to refine these casting techniques to meet industry demands effectively.

| Industry | Application | Material Used | Key Advantages |

|---|---|---|---|

| Aerospace | Components like turbine blades | Aluminum, Titanium | High precision, lightweight |

| Automotive | Engine components | Steel, Iron | Strength, durability |

| Medical | Surgical instruments | Stainless Steel, Cobalt Chrome | Biocompatibility, precision |

| Jewelry | Custom designs | Gold, Silver, Platinum | Intricate designs, fine detail |

| Oil & Gas | Valves and pumps | Nickel Alloys, Stainless Steel | Corrosion resistance, strength |

Lost wax investment casting stands out for its precision and details. This method allows manufacturers to create intricate designs without losing shape. A 2022 report by MarketsandMarkets estimated that the global investment casting market will reach $23.6 billion by 2027. This growth highlights the rising demand for high-quality components.

One primary advantage is the material efficiency achieved through lost wax casting. Up to 90% of the raw material is used, compared to only 50-60% in traditional casting processes. This efficiency reduces waste and lowers costs. Moreover, the process allows for thinner wall sections, creating lighter and stronger parts. For example, the aerospace industry benefits immensely from these properties, where weight reduction is crucial.

Despite its benefits, lost wax casting is not without challenges. The initial setup costs can be high. Setting up molds and patterns requires skilled labor. There’s also the risk of defects during the process, which can affect production timelines. Yet, the advantages often outweigh these drawbacks, pushing more industries to adopt this innovative method.

Lost wax investment casting has gained immense popularity in manufacturing across various industries. This method boasts precision, flexibility, and the ability to produce intricate designs. According to a recent industry report, the global investment casting market is expected to reach over $22 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.4%. This growth is largely attributed to the increasing demand for customized components and lightweight materials.

One contributing factor is the method's impressive dimensional accuracy. It allows manufacturers to create parts that require minimal machining. This reduces waste and production time, which is crucial in today’s fast-paced environment. The ability to work with a range of materials, including metals and alloys, further enhances its appeal. However, it's important to note that while this method offers many advantages, achieving the desired outcome consistently can be challenging.

Tips: Always conduct thorough quality checks. Inconsistencies may arise during the casting process. It’s crucial to understand each step deeply. Pay attention to the wax patterns. They play a significant role in the final product quality. A well-designed pattern can save time and resources.

Another factor is the eco-friendliness of lost wax casting. The process produces minimal waste compared to traditional methods. Some reports indicate that investment casting can lead to 50% less material waste. Yet, not all manufacturers have adopted eco-friendly practices. There's still room for improvement in sustainability measures.

Lost wax investment casting is revered for its precision and versatility. However, it is not without its challenges and limitations. One major concern is the cost related to the process. Depending on the complexity of the design, expenses can escalate quickly. A detailed report noted that over 30% of small manufacturers cite initial setup costs as a barrier to adoption.

Another challenge lies in the material limits. Not all alloys are suitable for lost wax casting. Some metals can cause defects or inconsistencies. For instance, aluminum and certain steel grades often pose problems during the casting phase. A significant percentage of inspections reveals imperfections that arise from inadequate material compatibility, resulting in increased rework and waste.

Moreover, time is a critical factor. The process can be relatively slow, often taking weeks to complete. This can hinder production schedules, especially in high-demand industries. A study indicated that approximately 25% of projects face delays due to the intricacies involved in the lost wax technique. Manufacturers must weigh the benefits against these challenges, leading to a careful consideration of their operational strategies.