+86 180 0293 5268

+86 180 0293 5268

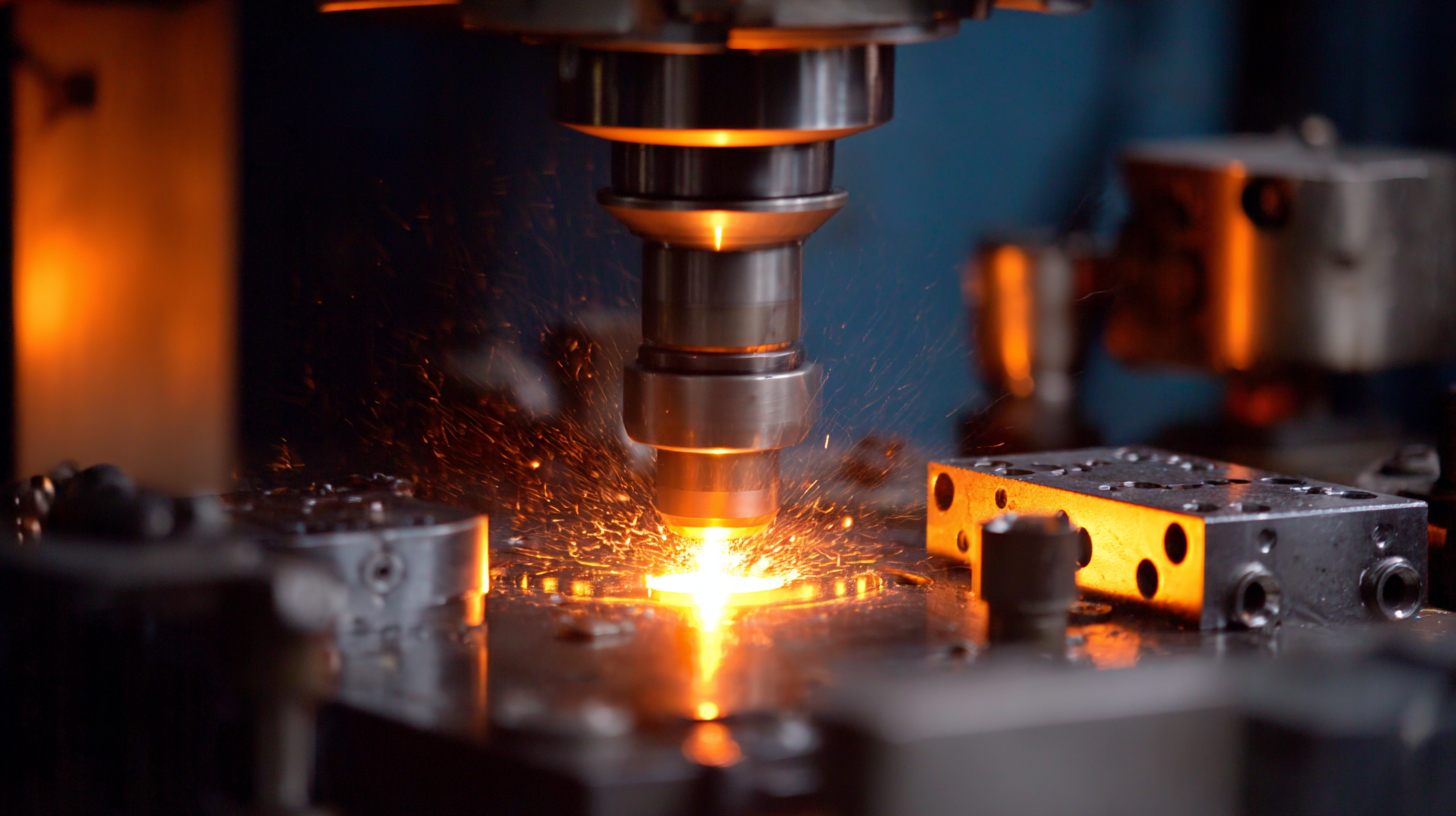

In recent years, Precision Investment Casting has emerged as a vital manufacturing process, significantly enhancing efficiency across various industries. According to a report by MarketsandMarkets, the global investment casting market is expected to reach USD 19.13 billion by 2025, growing at a CAGR of 5.8%. This growth is driven by the increasing demand for complex geometries and high-performance materials in sectors such as aerospace, automotive, and medical.

Precision Investment Casting allows manufacturers to produce intricate designs with exceptional tolerances, reducing the need for extensive machining and minimizing material waste. As companies strive for leaner production processes and improved product quality, mastering this technology becomes crucial for manufacturers aiming to stay competitive in an ever-evolving marketplace.

This article will explore key strategies and practices that can help businesses optimize their Precision Investment Casting processes for maximum manufacturing efficiency.

In recent years, Precision Investment Casting has emerged as a vital manufacturing process, significantly enhancing efficiency across various industries. According to a report by MarketsandMarkets, the global investment casting market is expected to reach USD 19.13 billion by 2025, growing at a CAGR of 5.8%. This growth is driven by the increasing demand for complex geometries and high-performance materials in sectors such as aerospace, automotive, and medical.

Precision Investment Casting allows manufacturers to produce intricate designs with exceptional tolerances, reducing the need for extensive machining and minimizing material waste. As companies strive for leaner production processes and improved product quality, mastering this technology becomes crucial for manufacturers aiming to stay competitive in an ever-evolving marketplace.

This article will explore key strategies and practices that can help businesses optimize their Precision Investment Casting processes for maximum manufacturing efficiency.

Precision investment casting is a sophisticated manufacturing process that allows for the creation of highly detailed metal parts. This technique involves creating a wax pattern, which is coated in a ceramic shell to form a mold. Once the shell hardens, the wax is melted away, leaving a cavity for molten metal. Understanding these fundamentals is crucial for optimizing efficiency in production.

**Tips:** First, ensure that the wax pattern is accurately designed to minimize the need for post-casting adjustments. This not only saves time but also enhances the precision of the final product. Second, pay close attention to the temperature control during the melting and pouring processes. Maintaining consistent temperatures can greatly reduce the occurrence of defects like porosity and improve overall quality.

Another vital aspect is the selection of the right materials. The choice of metal alloy can significantly impact the casting's mechanical properties and its suitability for various applications. Familiarizing yourself with different alloys and their characteristics will help in achieving the desired performance for your components. By mastering these techniques, manufacturers can enhance both their precision and overall manufacturing efficiency.

This bar chart illustrates the time required for each step in the precision investment casting process, demonstrating areas for potential efficiency improvements.

The choice of materials in precision investment casting significantly influences manufacturing efficiency and product performance. According to a report from the Investment Casting Institute, using high-quality alloys can reduce production defects by up to 30%, ultimately decreasing waste and saving on costs. Essential materials, such as stainless steels, titanium alloys, and superalloys, offer specific mechanical properties that enhance durability and strength, which are critical in high-performance applications like aerospace and medical devices.

Moreover, advancements in material science have led to the development of new composite materials that can withstand extreme temperatures and stresses. A recent study noted that employing advanced ceramic molds can improve thermal conductivity and reduce cycle times by approximately 15%. This shift not only increases output but also ensures greater precision in the casting process, proving that the right material selection is pivotal for optimizing manufacturing efficiency in the precision investment casting industry.

| Material Type | Melting Point (°C) | Density (g/cm³) | Thermal Conductivity (W/m·K) | Casting Precision (mm) | Production Cost ($/kg) |

|---|---|---|---|---|---|

| Stainless Steel | 1400 | 7.9 | 16.2 | 0.05 | 4.5 |

| Aluminum | 660 | 2.7 | 205 | 0.03 | 3.0 |

| Copper | 1085 | 8.96 | 401 | 0.04 | 6.5 |

| Bronze | 950 | 8.73 | 85 | 0.04 | 5.0 |

| Tool Steel | 1400 | 7.85 | 40 | 0.05 | 7.0 |

The design process for precision investment castings is crucial for optimizing manufacturing efficiency, particularly in industries that are seeing rapid growth, such as aerospace and automotive. According to recent forecasts, the investment casting market in China is expected to expand significantly between 2025 and 2031, driven by increased demand for high-quality components. This highlights the importance of refining design methodologies to enhance the precision and effectiveness of casting processes.

In the context of advanced manufacturing, integrating technology into the design phase can lead to substantial improvements. Employing sophisticated modeling software and simulation tools allows manufacturers to predict and mitigate potential defects early in the design process. Furthermore, advancements in materials and fine-tuning of casting parameters can lead to better yield rates and reduced waste. As the industry evolves, companies that invest in optimizing their design processes for precision investment castings will be well-positioned to capitalize on new market opportunities and respond to the dynamic demands of leading sectors.

Investment casting is a highly efficient method for producing complex metal parts with exceptional precision, but it is not without its challenges. Common issues in the production process can arise from a variety of factors, including material defects, incorrect temperatures, and inadequate mold designs. Addressing these issues requires a thorough understanding of the materials being used, as well as stringent quality control measures throughout the casting process.

Investment casting is a highly efficient method for producing complex metal parts with exceptional precision, but it is not without its challenges. Common issues in the production process can arise from a variety of factors, including material defects, incorrect temperatures, and inadequate mold designs. Addressing these issues requires a thorough understanding of the materials being used, as well as stringent quality control measures throughout the casting process.

As highlighted in recent advancements, particularly in aerospace applications, the significance of precision investment casting cannot be overstated. Techniques that enable the production of single-crystal turbine blades are essential for creating components capable of withstanding extreme temperatures, such as those found in jet engines. However, problems like contamination from pollutants can compromise the integrity of these blades, leading to operational failures. By implementing robust troubleshooting protocols, manufacturers can safeguard against these pitfalls, ensuring high-quality output and contributing to more efficient supply chains in the aerospace sector.

Implementing quality control measures in precision investment casting is crucial for achieving optimal manufacturing efficiency. An effective quality control strategy not only enhances output but also reduces waste and ensures that products meet stringent specifications. To implement these measures, manufacturers should focus on process monitoring, inspection protocols, and thorough testing methods throughout production.

**Tips:** Regularly calibrate your equipment to maintain accuracy in mold creation. Implement a systematic inspection process at various stages of production, ensuring any defects are identified and rectified immediately. Utilize statistical process control (SPC) techniques to analyze data from production runs, which can help detect variations that may affect product quality.

By prioritizing quality control, manufacturers can create a culture of excellence within their operations. Training staff to recognize and address potential issues during the casting process is essential. Encourage open communication among team members to share insights on quality improvements, making it an integral part of daily routines. This proactive approach can lead to significant advancements in manufacturing efficiency and product reliability.