+86 180 0293 5268

+86 180 0293 5268

In the rapidly evolving field of modern manufacturing, aerospace machining has emerged as a critical area of focus, driven by the increasing demand for precision and efficiency in aerospace component production. According to a report by MarketsandMarkets, the aerospace machining market is projected to reach $XX billion by 2025, growing at a CAGR of XX% due to advancements in technology and increased aircraft production rates. As manufacturers strive to meet stringent safety and performance standards, mastering aerospace machining techniques becomes essential for enhancing productivity and ensuring product quality.

This blog will outline the fundamental approaches and strategies that are integral to excelling in aerospace machining, empowering manufacturers to navigate challenges and leverage opportunities in this competitive sector.

Selecting the right materials for aerospace machining is critical for enhancing performance, especially in the context of advanced manufacturing technologies. The use of fiber-reinforced polymers, particularly carbon fiber reinforced polymers (CFRP), showcases how material characteristics can significantly influence the structural integrity and efficiency of aerospace components. Recent studies indicate that optimizing the upper adherend in CFRP adhesive-bonded joints involves a nuanced understanding of stress distribution, a concept further enhanced by numerical and machine learning approaches. Such methodologies not only streamline material selection but also open avenues for innovative design solutions tailored to meet the rigorous demands of aerospace applications.

Additionally, the integration of advanced manufacturing techniques, including additive manufacturing and nanotechnology, is revolutionizing material properties and applications. The ongoing research in carbon nanotube-polymer composites exemplifies how these technologies can enhance the performance of aerospace materials by making them lighter and more robust. As manufacturers continue to explore sustainable machining practices and cutting-edge tooling concepts, there is a clear trend towards embracing smarter materials and processes that promise not only to advance aerospace manufacturing but also to meet environmental considerations. This combined focus on material optimization and technological innovation is essential for achieving higher performance in modern aerospace machining.

In the aerospace manufacturing industry, the precision and efficiency of machining techniques have become pivotal in meeting the stringent standards of performance and safety. CNC milling and CNC turning are two of the most vital processes employed to produce intricate aerospace components. According to a report by the Aerospace Industries Association, advanced CNC machining technologies have significantly increased production efficiency by up to 30%, allowing manufacturers to keep pace with the rising demand for lightweight and robust parts.

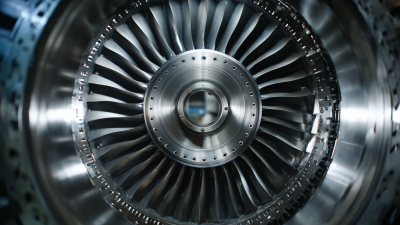

CNC milling stands out for its versatility, enabling the creation of complex geometries essential for components like turbine blades and structural frames. The Global Aerospace CNC Machining Market is projected to reach USD 4.3 billion by 2026, driven by the need for precision components that adhere to the highest quality standards. Simultaneously, CNC turning plays a crucial role in producing cylindrical parts such as shafts and fittings, where precision is non-negotiable. The ability to achieve tolerances as tight as ±0.005 mm ensures that each component not only meets design specifications but also contributes to the overall reliability of aerospace systems. Embracing these advanced machining techniques is vital for manufacturers aiming for excellence in this highly competitive field.

In the realm of aerospace machining, understanding tolerances is paramount. Geometric dimensioning and tolerancing (GD&T) plays a critical role in ensuring that the intricate designs of aerospace components are transformed into viable products without compromising quality. A recent study highlights that 70% of manufacturing defects can be traced back to insufficient understanding of tolerances during the design phase. By utilizing GD&T, engineers can create a language that bridges the gap between innovative design and practical manufacturing requirements, allowing for precise communication regarding size, form, orientation, and location of features.

Coordinate measuring machines (CMMs) are essential tools in this process, especially in the aerospace sector where strict tolerances are non-negotiable. These machines provide the capability to measure complex geometries accurately, ensuring that components meet the high standards demanded by the industry. Moreover, as manufacturers increasingly adopt Quality 4.0 principles, integrating CMMs with evolving inspection software allows for real-time data management and enhanced analysis of machining processes. This integration not only accelerates production but also helps in maintaining stringent quality control, which is vital for ensuring safety and reliability in aerospace applications.

| Technique | Description | Benefits | Common Applications | Challenges |

|---|---|---|---|---|

| Geometric Dimensioning and Tolerancing (GD&T) | A system for defining and communicating engineering tolerances. | Improves precision and reduces manufacturing costs. | Aircraft components, turbine engines. | Complexity and training requirements for staff. |

| Computer Numerical Control (CNC) Machining | Automated machining process controlled by computer programming. | High precision and repeatability in machining. | Fuselage components, wing structures. | Initial setup costs and maintenance of machines. |

| 5-Axis Machining | Machining process that moves tools on five different axes for complex shapes. | Ability to create intricate geometries and reduce setup time. | Engine components, structural parts. | Higher costs and skilled labor requirements. |

| Additive Manufacturing | Layer-by-layer construction of parts directly from 3D models. | Greater design freedom and reduction of material waste. | Lightweight structures, complex internal features. | Material limitations and slower production rates. |

| Quality Inspection Techniques | Methods for verifying that machined parts meet specifications. | Ensures compliance with strict aerospace standards. | Post-machining inspections in manufacturing. | Time-consuming and may require additional resources. |

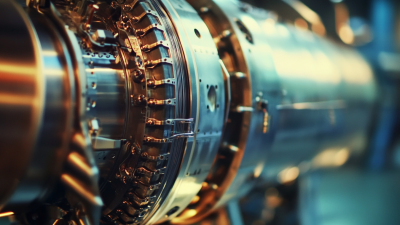

In the rapidly evolving landscape of aerospace machining, the adoption of advanced tooling technologies is pivotal for enhancing both quality and speed in production. The integration of CNC (Computer Numerical Control) machinery has transformed manufacturing processes, with projections indicating significant growth in the CNC machine market by 2032. This surge is driven by the increasing need for precise machining capabilities that meet the demanding standards of the aerospace sector. Reports indicate that advanced manufacturing techniques, including the combination of AI and 3D printing, are set to revolutionize productivity metrics, pushing aerospace manufacturers toward achieving unprecedented efficiency levels.

Moreover, standardized inspection tools and modular platforms are emerging as crucial components in tackling industry-wide challenges. These innovations not only streamline inspection processes but also enhance overall manufacturing efficiency. As the commercial aircraft backlog remains strong, driven by steady demand despite supply chain disruptions, manufacturers are leveraging these advanced technologies to ensure that they keep pace with production demands. This compelling synergy of tooling innovations and digital manufacturing technologies positions the aerospace industry to thrive in an ever-competitive global market.

In the rapidly evolving field of aerospace manufacturing, leveraging analytics to analyze machining data is crucial for optimizing processes and enhancing product quality. By employing advanced data analytics tools, manufacturers can gain insights into machine performance, material behavior, and operational efficiency. This approach not only reduces downtime but also helps in identifying areas for continuous improvement.

Tip 1: Implement real-time data monitoring systems to track key performance indicators (KPIs) such as cycle times, tool wear, and machine utilization. This data can provide immediate feedback and facilitate timely adjustments to your machining processes, ultimately leading to improved efficiency and reduced costs.

Tip 2: Utilize predictive analytics to foresee potential issues before they escalate. By analyzing historical machining data, manufacturers can identify patterns and trends that signal future disruptions, allowing for proactive maintenance and strategic decision-making that enhances overall productivity.

Furthermore, fostering a culture of data-driven decision-making within the organization encourages engineers and technicians to collaborate closely and share insights derived from machining data. This collective approach not only streamlines processes but also drives innovation in aerospace machining techniques.