+86 180 0293 5268

+86 180 0293 5268

The art of wax casting aluminum has gained significant traction in various industries, particularly in aerospace and automotive manufacturing, where precision and efficiency are paramount. According to a recent report by MarketsandMarkets, the global investment casting market is projected to reach $31.2 billion by 2025, with a substantial share attributed to advancements in wax casting techniques. This method, renowned for its ability to produce complex geometries with minimal waste, aligns perfectly with the growing demand for sustainable manufacturing practices. As we delve into mastering wax casting aluminum techniques, we will explore the intricate processes, essential tools, and best practices that not only enhance quality but also optimize production time and cost. Whether you are a seasoned professional or a budding enthusiast, understanding these techniques will empower you to achieve perfect results in your casting endeavors.

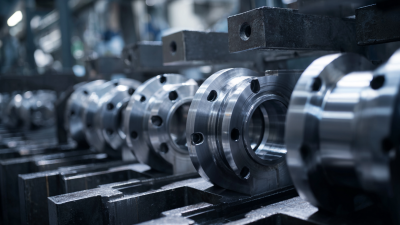

Wax casting aluminum is a fascinating technique that combines artistry with precision engineering. To achieve perfect results, having the right tools and materials is essential. At the core of this process is the wax model. High-quality casting wax is crucial as it ensures detailed reproduction of designs. It is typically softer and easier to carve, which allows for intricate shapes to be created with ease. Alongside wax, a reliable casting frame or investment material is necessary for forming the mold that will withstand high temperatures during the aluminum pour.

In addition to wax, other essential tools include a precise melting furnace capable of reaching the high temperatures required for aluminum, as well as a vacuum chamber for eliminating air bubbles during the casting process. A rotary tool can assist in fine-tuning and detailing the wax model. Safety equipment, such as gloves and goggles, should also be on hand to protect against heat and molten metal splashes. By gathering these essential tools and materials, artisans can embark on a creative journey that leads to flawless aluminum castings.

Creating wax patterns for aluminum casting is a technique that can significantly enhance the quality of the final product. According to a report by the American Foundry Society, utilizing the lost-wax casting process can improve dimensional accuracy by up to 0.1 mm, making it ideal for intricate designs. The first step in this process is to create a detailed wax model of the desired part. Make sure to use high-quality wax that can withstand the heat of the melting process, as this will influence the fidelity of the mold.

Once the wax pattern is constructed, the next phase involves coating it with a thin layer of ceramic material that forms the mold. This shell should be built-up through a series of dips and hardening cycles, which can significantly affect the durability of the mold. Industry reports indicate that molds created through this method can endure temperatures exceeding 1000°C, making them suitable for aluminum casting. After cooling, the wax is melted away, leaving behind a precise mold into which aluminum can be poured, ensuring the creation of economically viable, high-quality castings. This attention to detail and proper technique is essential for achieving perfect results in wax casting aluminum.

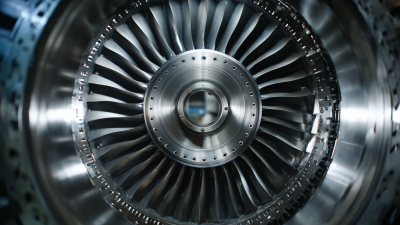

When it comes to wax casting aluminum, mastering the melting and pouring techniques is crucial for achieving flawless results. The melting process begins with selecting high-quality aluminum, which can significantly influence the final product's integrity. Choosing the right furnace is equally important; a propane or electric furnace with precise temperature controls will help maintain a consistent melting environment. Ideal melting temperatures typically range from 1,200°F to 1,400°F, ensuring that the aluminum becomes fluid enough to fill intricate molds without leaving air pockets or imperfections.

Once the aluminum has melted, the pouring technique becomes paramount. It's essential to pour the aluminum slowly and steadily to avoid turbulence, which can introduce air bubbles and defects in the casting. Using a ladle that retains heat can help maintain the aluminum’s temperature during the pouring process, ensuring a smooth flow. Additionally, pouring from a slight height can assist in achieving more even distribution within the mold. Practicing these techniques will not only enhance the quality of your casts but also build your confidence in working with aluminum, ultimately leading to consistently perfect results.

When it comes to achieving a flawless look for your cast aluminum parts, finishing and polishing are crucial steps in the wax casting process. After demolding, cast pieces often display rough surfaces and imperfections that can detract from their aesthetic appeal. To enhance the visual quality, begin by removing any excess material and rough edges using a combination of files and sanding techniques. It's essential to work methodically, progressing from coarser to finer grits to ensure a smooth surface.

Once initial shaping is complete, you can transition to the polishing stage. Utilizing a polishing wheel alongside suitable compounds helps to elevate the sheen of your aluminum parts significantly. For a high-gloss finish, consider using buffing pads made from cotton or foam, and apply a compound designed for aluminum. This not only enhances the appearance but also provides a layer of protection against oxidation. Regular maintenance through polishing will keep your cast aluminum parts looking pristine, ensuring they stand out in any project or setting.

When delving into the realm of wax casting aluminum projects, troubleshooting common issues is essential for achieving flawless outcomes. One of the primary problems craftspersons encounter is the degradation of wax patterns due to improper temperature management. A recent report highlighted that maintaining consistent temperatures, approximately 60-70 degrees Celsius, is crucial for optimal wax performance. Deviating from these temperatures can lead to wax distortion, ultimately affecting the final cast's precision and detail.

Another frequent issue arises from air bubbles trapped within the wax. According to industry studies, incorporating vibration techniques during the pouring process significantly reduces the incidence of air pockets, enhancing the quality of the final product. Additionally, the application of vacuum systems during the mold-making stage has been demonstrated to improve the fidelity of complex designs, allowing artisans to replicate intricate details more effectively. By understanding and addressing these common obstacles, artists can refine their aluminum casting techniques and achieve perfect results in their projects.