+86 180 0293 5268

+86 180 0293 5268

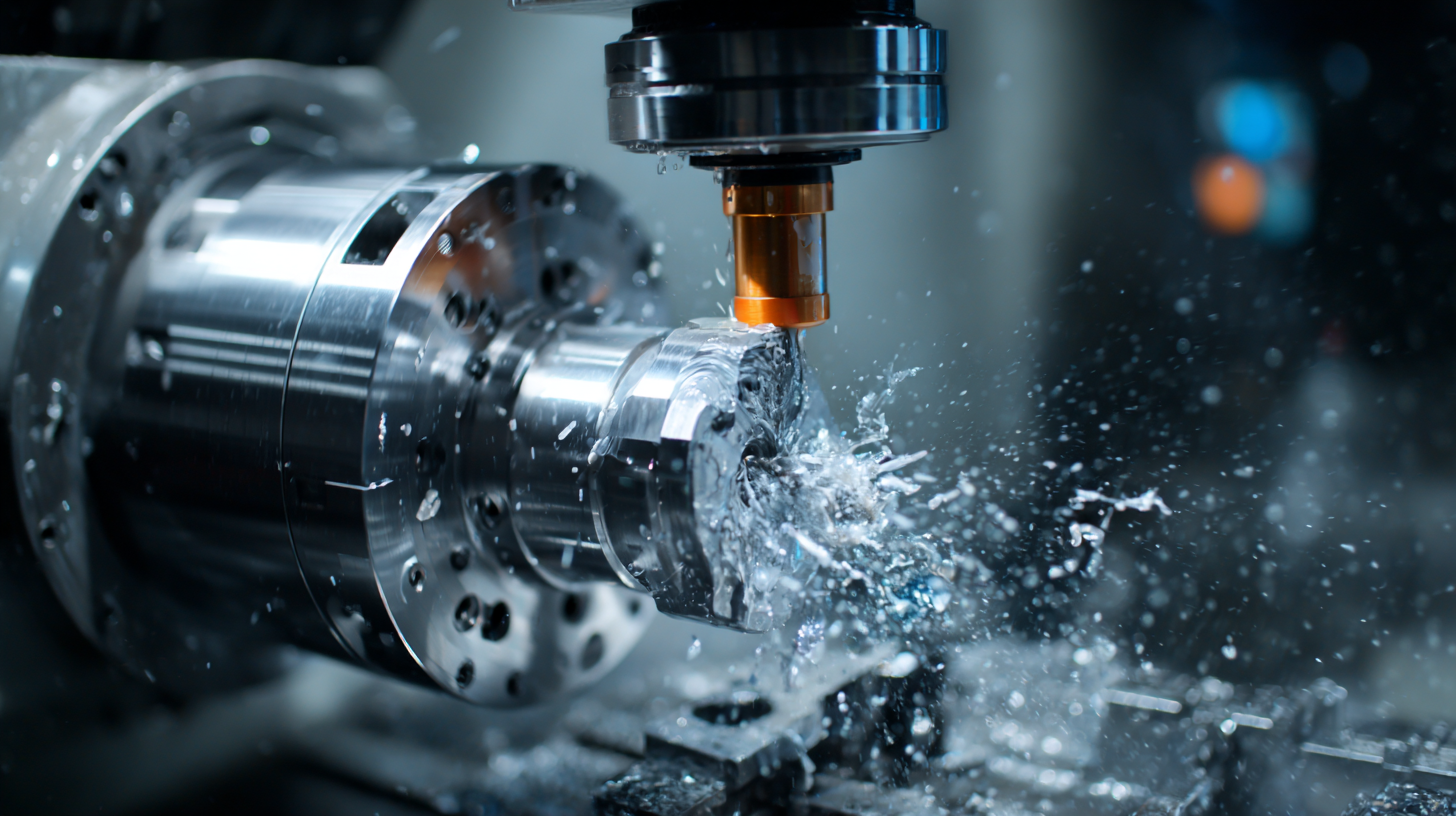

In the rapidly evolving landscape of manufacturing, CNC machining parts have become essential for industries demanding precision and efficiency. According to a recent market analysis by Grand View Research, the global CNC machining market is projected to reach $100 billion by 2025, with a compound annual growth rate (CAGR) of 8% from 2019. This growth is driven by advancements in technology and the increasing need for complex components across sectors such as aerospace, automotive, and medical devices.

As we navigate the future of CNC machining, it is crucial to understand the trends shaping this industry, particularly from world-class manufacturing hubs like China, which continues to lead in cutting-edge innovations and superior production capabilities. This comprehensive guide will explore the key trends impacting CNC machining parts and equip businesses with insights to thrive in this competitive landscape.

The CNC machining industry is on the brink of revolutionary changes as we approach 2025, driven by emerging technologies that are reshaping the landscape. With a projected market growth from $101.22 billion in 2025 to $195.59 billion by 2032, at a compound annual growth rate (CAGR) of 9.9%, the future looks promising for CNC machining parts. Key innovations such as artificial intelligence and robotics are increasingly integrated into the manufacturing process, enhancing efficiency and quality while reducing production costs.

As industries adapt to these advancements, metrology and quality assurance are becoming crucial components of the production cycle. Companies are increasingly using AI-driven applications to ensure precision in machining, which significantly improves product quality and innovation rates. Additionally, as manufacturing startups emerge and embrace these technologies, they are not only fostering competition but also accelerating the pace of development within the sector. With the industry's focus shifting towards sustainability and advanced manufacturing techniques, 2025 will undoubtedly mark a significant milestone in CNC machining evolution.

The demand for precision CNC machining parts is experiencing significant growth, driven by advancements across various sectors, including aerospace, automotive, and medical industries. According to a report by Grand View Research, the global CNC machining market is expected to reach USD 100 billion by 2025, with a compound annual growth rate (CAGR) of 6.5% from 2019 to 2025. This surge is largely attributed to the increasing need for higher accuracy and efficiency in manufacturing processes, as industries aim to reduce waste and enhance productivity.

Another key trend influencing this demand is the ongoing integration of Industry 4.0 technologies. The adoption of smart manufacturing, automated processes, and IoT-enabled machinery is transforming CNC machining capabilities. A study by MarketsandMarkets highlights that the smart manufacturing market is projected to grow from USD 236 billion in 2020 to USD 396 billion by 2025, pushing CNC machining parts towards greater customization and adaptability. As sectors become more reliant on data-driven insights, CNC machining parts that offer flexibility and precision will become indispensable, further driving market demand.

| Sector | Trend | Demand Driver | Projected Growth (%) |

|---|---|---|---|

| Automotive | Increased Electrification | Demand for lightweight components | 15% |

| Aerospace | Advanced Materials Usage | Need for fuel efficiency | 12% |

| Medical Devices | Customization and Precision | Growing demand for personalized solutions | 10% |

| Electronics | Miniaturization | Need for smaller, more efficient parts | 8% |

| Defense | Rapid Prototyping | Need for quick response capabilities | 5% |

As the CNC machining industry evolves, sustainability has emerged as a crucial focus for manufacturers aiming to meet the demands of an eco-conscious market. According to a recent report by the International Federation of Robotics, the global market for sustainable manufacturing practices, including CNC machining, is projected to grow at a CAGR of 9.5% from 2021 to 2026. This shift not only reflects a growing commitment to environmental stewardship but also aligns with increasing regulatory pressures and consumer preferences for greener products.

To stay competitive in 2025 and beyond, CNC machining companies are adopting eco-friendly practices such as utilizing recyclable materials and energy-efficient machinery. The use of biodegradable coolants and lubricants is on the rise, with a study from McKinsey & Company indicating that up to 40% of companies in the manufacturing sector are making substantial investments in sustainable technology. Furthermore, implementing lean manufacturing principles can lead to reductions in waste and energy consumption, achieving both operational efficiencies and environmental benefits. As the demand for sustainable parts increases, it’s clear that integrating these practices into CNC machining will not only enhance brand reputation but also drive long-term profitability.

As we look towards 2025, the integration of automation and artificial intelligence (AI) in CNC machining is set to revolutionize the industry. The implementation of these technologies is not merely an enhancement but a transformative shift that increases both efficiency and quality. Automated systems are streamlining production processes, enabling manufacturers to minimize human error, optimize workloads, and significantly reduce cycle times. This allows for a faster turnaround on projects without sacrificing precision, thereby catering to the ever-increasing demand for high-quality machined parts.

AI algorithms play a crucial role in predictive maintenance and process optimization. By analyzing real-time data collected from CNC machines, AI can foresee potential equipment failures before they occur, thereby reducing downtime and maintenance costs. Additionally, AI enhances the programming of CNC machines, allowing for adaptive learning based on previous machining outcomes. This results in continuous improvement and makes it possible to produce complex geometries with unparalleled accuracy. As we navigate the future, the synergy between automation and AI will undoubtedly reshape the landscape of CNC machining, making it more efficient, reliable, and capable of meeting the diverse needs of various industries.

The landscape of CNC machining is rapidly evolving, with innovations in materials driving a new wave of industrial applications. According to recent industry reports, the global CNC machining market size is projected to reach $100 billion by 2025, expanding at a CAGR of 6.3% from 2020. This growth is significantly influenced by advancements in high-performance materials such as carbon fiber, titanium alloys, and advanced polymers. These materials not only provide superior strength-to-weight ratios but also enhance the machining process by reducing wear on tooling and improving surface finishes.

Innovations in additive manufacturing are also reshaping the future of CNC machining. With the rise of metal 3D printing technologies, manufacturers can now create complex geometries that were once impossible to achieve with traditional machining methods. A recent report highlighted that 3D printing in CNC machining could reduce production time by up to 70%, allowing for more efficient workflows and reduced costs. As industries continue to demand lighter, stronger components—especially in aerospace and automotive sectors—embracing these innovative materials and techniques will be key to staying competitive in 2025 and beyond.