+86 180 0293 5268

+86 180 0293 5268

In today's rapidly evolving manufacturing landscape, the significance of CNC machined parts cannot be overstated. According to a recent report by MarketsandMarkets, the CNC machining market is projected to reach USD 100.35 billion by 2026, exhibiting a CAGR of 6.91% from 2021 to 2026. This growth underscores the pivotal role CNC machined parts play in enhancing precision, efficiency, and the overall quality of manufactured products across various industries, including aerospace, automotive, and medical devices.

As manufacturers increasingly adopt advanced CNC technology, they are unlocking new levels of customization and performance, driving innovation and competitiveness in the global market. By prioritizing the integration of CNC machined parts into their operations, companies are not only optimizing their production processes but also meeting the ever-demanding requirements of modern consumers for precision-engineered solutions.

In recent years, CNC machining technology has seen significant advancements, fundamentally transforming the manufacturing landscape. The emergence of smart manufacturing and Industry 4.0 is at the forefront of these trends, allowing for more autonomous operations and data-driven decision-making. With the integration of IoT devices and AI-driven analytics, manufacturers can optimize production processes, reduce downtime, and enhance the precision of machined parts. This shift not only increases efficiency but also opens up the potential for customization, enabling companies to meet unique customer demands with greater agility.

To stay competitive in this rapidly evolving environment, companies should consider adopting cloud-based CNC solutions. Cloud technology facilitates real-time data sharing and collaboration among teams, streamlining the workflow from design to production. Additionally, investing in training programs for employees to familiarize them with the latest CNC technologies can drive innovation and improve overall productivity.

Lastly, incorporating additive manufacturing techniques into traditional CNC processes is becoming a game changer. By leveraging hybrid machining systems, manufacturers can combine the best of both worlds, producing complex geometries that were previously impossible with conventional methods. Embracing these emerging trends will not only enhance the precision of machined parts but also empower manufacturers to lead in an ever-competitive market.

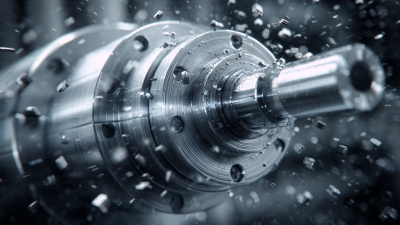

CNC machining has transformed the landscape of modern manufacturing by enhancing efficiency and precision. As industries increasingly demand high-quality components, the role of CNC (Computer Numerical Control) technology becomes paramount. Unlike traditional machining methods, CNC machines operate with a remarkable level of accuracy, allowing manufacturers to produce complex shapes and intricate designs with minimal human intervention. This precision not only reduces waste but also shortens production cycles, leading to faster turnarounds and increased responsiveness to market needs.

Furthermore, the integration of CNC machining into manufacturing processes facilitates the optimization of resource utilization. Advanced software algorithms enable manufacturers to plan and execute machining tasks effectively, ensuring that every cut and operation is performed with maximum efficiency. This capability not only contributes to cost savings but also promotes sustainability by minimizing material use. As manufacturers continue to adopt CNC technologies, they are finding new avenues to innovate and improve their operational workflows, solidifying CNC machining's role as a cornerstone of modern manufacturing efficiency.

The landscape of CNC machined parts is rapidly evolving, particularly through the introduction of innovative materials that enhance manufacturing capabilities. According to a report by MarketsandMarkets, the global CNC machining market is expected to reach $100 billion by 2025, with advanced materials playing a crucial role in this growth. One noteworthy advancement is the use of lightweight composites, such as carbon fiber-reinforced plastics, which provide remarkable strength-to-weight ratios. These composites are increasingly favored in industries ranging from aerospace to automotive, where performance and fuel efficiency are paramount.

Moreover, the rise of additive manufacturing techniques has paved the way for new metallic alloys that exhibit superior mechanical properties. A comprehensive report by Wohlers Associates highlights that metal 3D printing is projected to grow at a CAGR of 33% from 2020 to 2025. As a result, CNC machining can now utilize these specialized alloys, offering enhanced durability and resistance to corrosion in high-stress applications. By leveraging these innovative materials, manufacturers can not only improve product performance but also address sustainability goals, ultimately revolutionizing the modern manufacturing landscape.

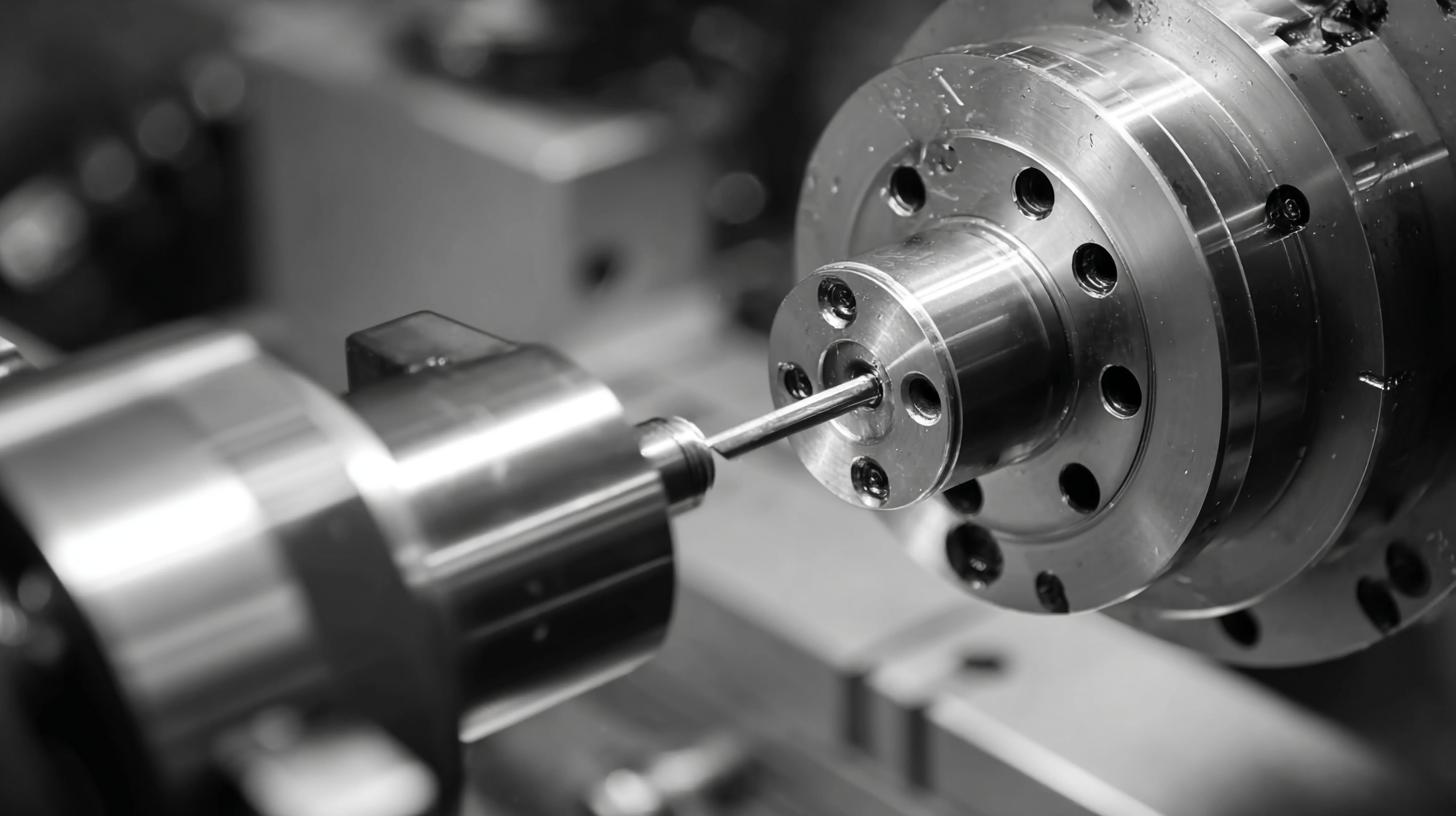

CNC machining has emerged as a cornerstone of modern manufacturing, finding applications across diverse industries. The technology has transformed how components are produced, enabling precision and efficiency that were previously unattainable. For instance, advancements in CNC machining technology, as seen through the efforts of various companies, have led to the development of high-quality stainless steel components that meet rigorous industry standards. This evolution is not only enhancing product reliability but is also streamlining production processes, contributing to significant reductions in lead times.

Industries such as automotive and aerospace are leveraging CNC machining's capabilities to produce intricate parts with remarkable accuracy. Furthermore, the integration of hybrid manufacturing approaches, combining traditional CNC methods with advanced additive technologies, is expanding the potential applications of machined parts. This innovative approach exemplifies how the intersection of digital manufacturing and CNC technology is shaping the future, allowing for more flexible and versatile production solutions in a competitive marketplace. Industries are witnessing an unprecedented shift towards smarter manufacturing, driven by continuous improvements in CNC machined parts.

As the demand for precision in CNC machining continues to escalate, manufacturers face several challenges that can impact production efficiency and product quality. According to a recent report from the International Journal of Advanced Manufacturing Technology, inaccuracies in machining processes can lead to defects that increase production costs by up to 30%. One of the central issues is tool wear, which affects the dimensional accuracy of machined parts. Regular monitoring and updating of tooling strategies are vital to mitigating these wear effects.

To counter these challenges, integrating advanced technologies such as predictive maintenance and real-time monitoring can significantly enhance precision. A study by the Manufacturing Technology Centre indicates that companies implementing these solutions have seen improvements in accuracy rates by over 25%. Additionally, utilizing simulation software during the design phase can help identify potential issues before they manifest on the shop floor, leading to improved efficiency.

**Tip:** Regularly investing in training for CNC operators can lead to better understanding and utilization of advanced machinery, which in turn enhances precision.

Investing in high-quality materials is also crucial. A report from the American Society of Mechanical Engineers suggests that using high-grade raw materials can improve product consistency and reduce defects, ensuring more reliable machining processes.