+86 180 0293 5268

+86 180 0293 5268

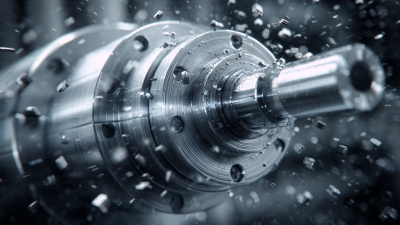

In today's competitive manufacturing landscape, the utilization of

Precision CNC Machining Parts has emerged as a critical factor in enhancing product quality across various industries.

According to a report by MarketsandMarkets, the global CNC machining market is projected to reach

$100 billion by 2025, driven by the demand for high-precision components in sectors such as aerospace, automotive, and medical devices.

Precision CNC machining not only ensures tighter tolerances but also significantly reduces material waste, contributing to sustainability efforts.

As manufacturers increasingly seek to optimize efficiency and quality, the integration of advanced CNC machining technologies becomes essential.

By addressing common challenges such as dimensional accuracy and surface finish,

Precision CNC Machining Parts can play a pivotal role in delivering superior products that meet consumer demands and regulatory standards.

In today's competitive manufacturing landscape, the utilization of

Precision CNC Machining Parts has emerged as a critical factor in enhancing product quality across various industries.

According to a report by MarketsandMarkets, the global CNC machining market is projected to reach

$100 billion by 2025, driven by the demand for high-precision components in sectors such as aerospace, automotive, and medical devices.

Precision CNC machining not only ensures tighter tolerances but also significantly reduces material waste, contributing to sustainability efforts.

As manufacturers increasingly seek to optimize efficiency and quality, the integration of advanced CNC machining technologies becomes essential.

By addressing common challenges such as dimensional accuracy and surface finish,

Precision CNC Machining Parts can play a pivotal role in delivering superior products that meet consumer demands and regulatory standards.

In modern manufacturing, precision CNC machining plays a vital role in enhancing product quality. According to a report by Grand View Research, the global CNC machining market is expected to reach USD 100.65 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.6%. This growth can be attributed to the increasing demand for high precision components across various industries, including aerospace, automotive, and medical devices. By utilizing precision CNC machining, manufacturers can achieve tighter tolerances, which results in improved fit and function of parts, ultimately contributing to higher product reliability.

Moreover, the integration of advanced CNC technologies facilitates automation and reduces human error, significantly improving production efficiency. A study by the National Association of Manufacturers (NAM) highlights that companies employing CNC machining experience a 25% reduction in production time and a 50% decrease in waste. These improvements not only elevate the quality of the final products but also enhance overall operational efficiency. As industries strive for innovation and competitive advantage, embracing precision CNC machining becomes crucial for achieving superior craftsmanship and sustaining high standards in product quality.

Traditional machining processes have long been the backbone of manufacturing, but they come with a set of common challenges that can compromise product quality. One major issue is the reliance on manual setups, which can lead to inconsistencies and variations in dimensions. This human error can result in defective parts, increased waste, and ultimately higher production costs. Additionally, traditional methods often involve longer lead times due to the need for frequent adjustments and recalibrations, slowing down the overall production process.

Another significant challenge is the limitations in the complexity of designs that traditional machining can handle. Complex geometries often require multiple setups or extensive tooling modifications, which not only complicates the process but also increases the risk of errors. Moreover, traditional machining techniques may not be able to achieve the precise tolerances required for high-performance applications, leading to subpar product quality. By addressing these obstacles through techniques like precision CNC machining, manufacturers can significantly enhance product quality and operational efficiency.

Precision CNC machining has emerged as a crucial solution to many common manufacturing challenges. A report from the International Journal of Advanced Manufacturing Technology indicates that about 30% of manufacturing defects stem from dimensional inaccuracies in parts (IJAMT, 2020). By employing precision CNC machining, manufacturers can achieve tolerances within ±0.005 inches. This level of accuracy significantly reduces rework and scrap rates, addressing one of the primary issues faced in mass production.

Furthermore, precision CNC machining enhances product quality through its ability to work with a diverse range of materials, including metals, plastics, and composites. According to a survey conducted by the Manufacturing Institute, 75% of manufacturers acknowledge that using advanced machining technologies has improved their overall operational efficiency. With CNC machines capable of intricate cuts and complex geometries, manufacturers can innovate and create parts that meet precise specifications, ultimately leading to enhanced product performance and customer satisfaction. As such, the adoption of precision CNC machining not only minimizes common pitfalls in manufacturing but also drives significant improvements in quality and efficiency across various industries.

The impact of high-quality machined parts on overall product performance cannot be overstated. Precision CNC machining offers manufacturers the ability to produce intricate and exact components that directly enhance the functionality and reliability of their products. With rising consumer expectations and stringent industry standards, utilizing meticulously crafted parts ensures that each product delivers optimal performance, reduces the likelihood of failure, and enhances user satisfaction.

Moreover, the integration of advanced technologies, such as three-dimensional scanning and digital twin data, is revolutionizing the manufacturing ecosystem. By leveraging these innovations, companies can achieve finer tolerances and better quality control, fostering an environment of efficiency and precision. This not only drives improved performance across various applications, from automotive parts to medical devices but also facilitates a shift toward smarter, more automated manufacturing processes. As the industry continues to evolve, the role of high-quality machining becomes foundational in meeting the challenges of modern production demands.

The future of precision CNC machining is on the forefront of technological advancements, significantly enhancing production quality across various industries. As laser processing continues to evolve, the integration of precision CNC machining parts allows manufacturers to achieve tighter tolerances and higher efficiencies. Recent industry reports indicate that 70% of manufacturers are increasingly adopting CNC technology to improve their production capabilities, resulting in a substantial reduction in material waste and increased operational accuracy.

Emerging trends in precision CNC machining demonstrate the growing importance of automation and smart manufacturing. Technologies such as AI and IoT are being interwoven into CNC processes, enabling real-time monitoring and predictive maintenance, which can decrease downtime by 30%. Additionally, the rise of additive manufacturing techniques in conjunction with CNC machining opens new avenues for complex geometries and lightweight designs, ultimately contributing to enhanced product quality and performance.

As these innovations mature, manufacturers can expect not only to improve their product specifications but also to elevate their competitive edge in the market.