+86 180 0293 5268

+86 180 0293 5268

The 138th China Import and Export Fair in 2025 stands as a pivotal platform for showcasing innovative advancements across various industrial sectors, with a particular emphasis on Precision Machining Parts. As the demand for high-quality, precision-engineered components increases globally, this event serves as a critical hub for industry leaders, suppliers, and manufacturers to explore emerging trends and forge valuable partnerships.

Attendees will have the unique opportunity to engage with cutting-edge technologies and materials that are transforming the landscape of precision machining. With a focus on sustainability and efficiency, the fair will highlight the latest advancements in production processes, enabling businesses to meet the evolving needs of various applications.

This exploration of Precision Machining Parts at the fair not only promises to reveal insights into the current market dynamics but also unveils a multitude of opportunities for collaboration and innovation, positioning participants at the forefront of industry development.

Attendees will have the unique opportunity to engage with cutting-edge technologies and materials that are transforming the landscape of precision machining. With a focus on sustainability and efficiency, the fair will highlight the latest advancements in production processes, enabling businesses to meet the evolving needs of various applications.

This exploration of Precision Machining Parts at the fair not only promises to reveal insights into the current market dynamics but also unveils a multitude of opportunities for collaboration and innovation, positioning participants at the forefront of industry development.

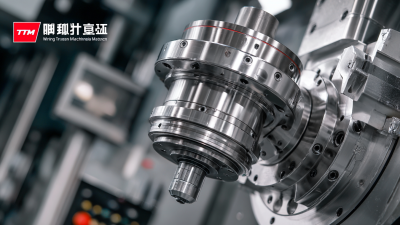

At the upcoming 138th China Import and Export Fair in 2025, the spotlight will be on innovative technologies in precision machining, reflecting the industry's rapid evolution and the incorporation of advanced solutions. Recent reports highlight that the global precision machining market is projected to reach USD 24 billion by 2025, driven by advancements in manufacturing technologies and increased demand across various sectors, including automotive and aerospace. This fair will serve as a platform for manufacturers to demonstrate their groundbreaking innovations, aligning with trends seen at other international events.

A notable trend is the integration of digital technologies with traditional machining processes. For instance, the adoption of CNC (Computer Numerical Control) systems has seen a significant uptick, with installations expected to rise by over 15% annually until 2026. Exhibitors will likely showcase enhanced automation solutions and intelligent manufacturing systems designed to optimize precision, reduce waste, and increase efficiency. With the emphasis on Smart Manufacturing, participants can expect insights into how these technologies can transform operational capabilities and drive competitiveness in the precision machining landscape.

As we delve into the key trends shaping the precision machining industry in 2025, a notable focus is on the increasing adoption of advanced laser equipment. The laser processing tools, including laser marking machines, welding machines, and cutting machines, have rapidly evolved, catering to various applications in the automotive and metallurgical industries. The market for precision machining parts is projected to experience robust growth, with reports indicating a significant uptick in demand due to the industrial upgrade initiatives that are redefining manufacturing paradigms.

Moreover, the CNC machining center market also showcases considerable potential, with forecasts estimating its value to reach $14.34 billion by 2025, an increase propelled by the ongoing technological advancements in smart manufacturing. As manufacturers seek higher efficiency and precision, the integration of intelligent systems and AI in production processes is becoming crucial. With the Chinese machine tool industry continuing to dominate global production and consumption, key players are strategically investing in innovative capabilities to remain competitive in this rapidly evolving landscape.

The 138th China Import and Export Fair in 2025 offers an excellent platform for professionals in precision machining to network and explore collaborative opportunities. As the industry evolves with advanced technologies such as artificial intelligence and machine learning, creating robust networks is crucial for sharing insights and fostering partnerships. A recent study highlights that precision machining contributes to over 20% of the global manufacturing output, underscoring its significance within the industry. Engaging with peers at this event can lead to valuable discussions about trends, challenges, and innovative solutions in precision machining.

Tips for Networking at the Fair:

The global supply chain dynamics have significantly influenced the precision machining parts industry, particularly as we approach the 138th China Import and Export Fair in 2025. With a projected market growth rate of 6% by 2027, driven by the increasing demand for automation and high-precision components in industries such as aerospace, automotive, and electronics, manufacturers must adapt to evolving supply chain factors. Reports indicate that disruptions in supply chains can lead to up to 30% delays in production timelines, underscoring the need for resilience and flexibility in sourcing and logistics.

To navigate these complexities effectively, companies should prioritize building strong relationships with suppliers and diversifying their supply chains. Implementing just-in-time inventory systems can help mitigate risks associated with overstocking while ensuring that production remains uninterrupted.

Tips: Focus on local sourcing to reduce dependency on international suppliers, which can decrease lead times and enhance response times to market changes. Additionally, investing in advanced technologies like AI and IoT can improve predictive analytics for supply chain management, enabling businesses to foresee disruptions and adapt proactively. As the fair approaches, leveraging insights from industry experts will be crucial for gaining a competitive edge in this rapidly evolving landscape.

The 138th China Import and Export Fair in 2025 has put a significant spotlight on sustainable practices within the precision machining industry. As the global market increasingly emphasizes environmental responsibility, the importance of adopting eco-friendly methodologies cannot be overstated. According to a recent report by MarketsandMarkets, the precision machining market is expected to reach USD 19.2 billion by 2027, growing at a CAGR of 8.6%. This growth presents a valuable opportunity for manufacturers to implement sustainable techniques, enhancing both efficiency and competitiveness.

Organizations attending the fair are showcasing innovations such as energy-efficient machinery, biodegradable lubricants, and recycling systems designed to minimize waste. By integrating these sustainable practices, companies not only comply with increasing regulatory standards but also appeal to a broader base of environmentally conscious consumers. It's essential for businesses to stay ahead of this trend to maximize their market presence.

Tips for embracing sustainability in precision machining: Firstly, consider conducting an energy audit to identify areas for improvement in your production processes. Secondly, invest in modern machinery that utilizes less energy and produces less waste. Finally, engage your workforce in sustainability initiatives, encouraging suggestions and participation in eco-friendly practices to foster a culture of responsibility within your organization.

This bar chart illustrates the key opportunities identified in precision machining at the 138th China Import and Export Fair in 2025, highlighting the importance of sustainability, technology adoption, market demand, innovation, and cost efficiency.