+86 180 0293 5268

+86 180 0293 5268

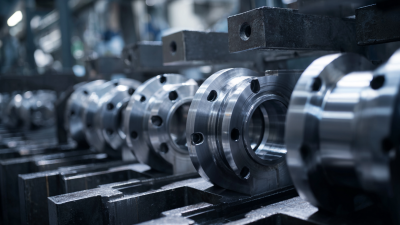

In the realm of modern manufacturing, precision machining parts have emerged as fundamental components that drive both efficiency and innovation. These meticulously crafted parts are characterized by their exceptional accuracy and intricate designs, which are essential for a wide array of applications across diverse industries, from aerospace to automotive. As the demand for higher quality and performance continues to escalate, understanding the significance of precision machining parts becomes imperative.

This blog will delve into the intricacies of these components, exploring their types, processes, and the pivotal role they play in enhancing product reliability and functionality. By examining real-world examples, we aim to shed light on how precision machining is not just a technical process but a critical factor in sustaining competitive advantage in today's fast-paced manufacturing landscape.

Precision machining is a critical component of modern manufacturing, defined by its ability to create parts with exacting tolerances and superior finishes. This discipline utilizes advanced cutting techniques and state-of-the-art machinery to produce components that meet stringent specifications. In industries ranging from aerospace to medical devices, precision machining ensures that each component functions seamlessly within complex systems, contributing to overall product reliability and performance.

The importance of precision machining in manufacturing cannot be overstated. With the aim of producing high-quality products rapidly and cost-effectively, manufacturers rely on precision parts to enhance efficiency and reduce waste. Technologies like CNC machining and automation further refine this process, allowing for real-time monitoring and data acquisition to optimize production. As intelligent manufacturing evolves, the integration of artificial intelligence is driving precision machining to new heights, enabling unparalleled levels of customization and adaptability in response to market demands. This evolution underlines the value of precision machining in maintaining a competitive edge and achieving operational excellence in today's fast-paced manufacturing landscape.

| Aspect | Details |

|---|---|

| Definition | Precision machining involves the process of removing material to create parts with high dimensional accuracy. |

| Applications | Used in industries such as aerospace, automotive, medical devices, and electronics. |

| Key Processes | CNC machining, EDM (Electrical Discharge Machining), grinding, and turning. |

| Material Types | Common materials include aluminum, steel, titanium, and plastics. |

| Importance | Ensures that parts meet strict tolerance requirements which is critical for functionality and safety. |

| Quality Control | Utilizes advanced inspection tools like coordinate measuring machines (CMM) to verify dimensions. |

Precision machining parts are essential components in various manufacturing processes, playing a pivotal role in ensuring accuracy and efficiency. There are several common types of precision machining parts that are widely used in the industry. For instance, CNC machined components are highly regarded for their ability to produce intricate designs with tight tolerances, making them ideal for industries such as aerospace and automotive. The demand for these parts has grown significantly, with market reports projecting a CAGR growth rate of about 5% in the global CNC machining market by 2026.

In addition to traditional CNC parts, there are alternative manufacturing methods, such as additive manufacturing, which has seen a surge in popularity. The latest advancements in 3D printing technologies, including a variety of filament types, allow for high-performance prototypes and production parts to be created faster and with less waste. 3D printing materials, ranging from standard PLA to specialized PEEK filaments, are now recognized for their unique properties and best-use cases, thereby expanding the scope of precision parts in modern applications.

Moreover, the integration of advanced software and computer simulations in CNC processes enhances design precision and reduces the risk of errors caused by mechanical backlash in servo control systems. This innovation is driving the evolution of precision machining parts, keeping them at the forefront of modern manufacturing solutions.

Precision machining parts are pivotal in modern manufacturing, and the materials used in this process significantly influence the quality and performance of the end products. Common materials include metals like aluminum, stainless steel, and titanium, which are favored for their strength and durability. According to a report by Grand View Research, the global precision machining market was valued at approximately $2.7 billion in 2022, with aluminum and stainless steel dominating the material choices due to their excellent machinability and corrosion resistance.

In addition to metals, advanced composites and polymers are increasingly being utilized in precision machining applications. These materials offer benefits such as reduced weight and enhanced thermal stability, making them ideal for industries like aerospace and automotive. A study by MarketsandMarkets forecasts that the composite materials market will grow from $80 billion in 2021 to $100 billion by 2026, driven by the demand for lightweight components that do not compromise on strength. This shift towards diverse materials not only enhances the performance of precision-machined parts but also supports sustainable manufacturing practices.

Precision machining plays a pivotal role in modern manufacturing, offering significant advantages over traditional machining techniques. According to a report by Markets and Markets, the global precision machining market is projected to reach $88.85 billion by 2026, growing at a CAGR of 7.5% from 2021. This growth is largely attributed to the increasing demand for high-quality components in industries like aerospace, automotive, and medical devices, where tolerances are crucial. Traditional manufacturing methods, which often rely on labor-intensive processes, are increasingly being replaced by precision machining due to their ability to produce complex geometries with minimal human error.

One of the key distinctions between precision machining and traditional techniques lies in their efficiency and accuracy. According to a study from SME, precision machining can achieve tolerances as tight as ±0.0001 inches, compared to ±0.005 inches typically observed in traditional methods. This level of precision not only reduces waste but also significantly shortens production cycles, thus driving down costs in the long term. Moreover, the integration of CNC (Computer Numerical Control) technology in precision machining enhances consistency and repeatability, which is a critical factor in industries that require high-quality components with every batch produced. As manufacturers seek to improve their operations, the shift towards precision machining is becoming increasingly evident.

Precision machining parts play a vital role across various industries by enabling the manufacture of highly intricate and accurate components. Leveraging advanced machining technologies, sectors such as aerospace, automotive, and medical devices benefit from components that meet stringent tolerances and performance requirements. For instance, in the medical device manufacturing arena, the integration of laser machining alongside traditional methods is enhancing the production of precision parts, ensuring quality and efficiency.

Precision machining parts play a vital role across various industries by enabling the manufacture of highly intricate and accurate components. Leveraging advanced machining technologies, sectors such as aerospace, automotive, and medical devices benefit from components that meet stringent tolerances and performance requirements. For instance, in the medical device manufacturing arena, the integration of laser machining alongside traditional methods is enhancing the production of precision parts, ensuring quality and efficiency.

Tips for choosing the right precision machining partner include assessing their technological capabilities and expertise in specific applications. Ensure they utilize modern methods like electrical discharge machining and laser machining to stay competitive in the fast-evolving landscape. Additionally, consider their quality assurance processes, as rigorous testing can significantly affect the reliability of the finished product.

As industries continue to adopt new digital manufacturing technologies, understanding the unique applications of precision machining parts becomes essential. Emphasize collaboration with machining specialists who can provide insights into suitable materials and design enhancements, ensuring optimal results for your manufacturing needs.