+86 180 0293 5268

+86 180 0293 5268

Precision metal machining is a critical aspect of modern manufacturing. This process involves the accurate shaping and finishing of metal components to tight tolerances. According to a recent report by Industry Research, the precision metal machining market is expected to grow by 7% over the next five years. This growth reflects the increasing demand for customized metal parts across various industries, including aerospace and automotive.

Dr. Emily Carter, a leading expert in precision engineering, emphasizes, “Precision Metal Machining is the backbone of innovation in manufacturing.” Her insight highlights the role of precision machining in enhancing product quality and performance. Despite its advancements, the industry faces challenges. Many companies struggle with maintaining efficiency and reducing waste.

Moreover, the skills gap in the workforce poses a significant concern. The technology is evolving, but finding qualified operators and engineers remains tough. As the industry continues to grow, stakeholders must address these shortcomings. This reflection is crucial to harnessing the full potential of Precision Metal Machining. It is a field where the future is promising, yet it demands constant improvement and adaptation.

Precision metal machining is a manufacturing process that shapes metal components with high accuracy. It involves removing material from a workpiece to achieve precise dimensions and fine finishes. Various techniques such as turning, milling, and grinding are commonly used. Each method has its purpose and can create complex geometries.

When utilizing precision machining, understanding the capabilities of your equipment is crucial. Some machines excel at producing intricate designs. Others may not meet the same specifications. It’s vital to choose the right tool for each task. Regular maintenance of the machinery will improve accuracy and prolong its lifespan.

Tips: Always double-check measurements before cutting. Small errors can lead to significant issues. Use high-quality raw materials to ensure better results. Inconsistent materials can affect the final product's quality. Lastly, maintain a clean working environment. Dirt and debris can compromise precision and lead to costly mistakes.

Precision metal machining is essential in various industries. It creates high-quality parts with exact dimensions. Several key processes define this field, each with unique functions.

CNC machining is one crucial process. It uses computer-controlled tools to cut metal precisely. This method can create complex shapes. However, programming errors may lead to inaccuracies. Regular checks and adjustments are vital.

Another important method is turning. Here, a rotating metal piece is shaped by a stationary cutting tool. This process can produce smooth cylindrical surfaces. Yet, achieving the right balance of speed and pressure can be challenging. Too much pressure may cause tool wear or part damage.

Milling is also significant in precision machining. It involves moving the workpiece against a rotating cutter. This method is ideal for flat surfaces and intricate designs. But, ensuring the right angle and depth is often tricky. Misalignment can affect the quality of the final product.

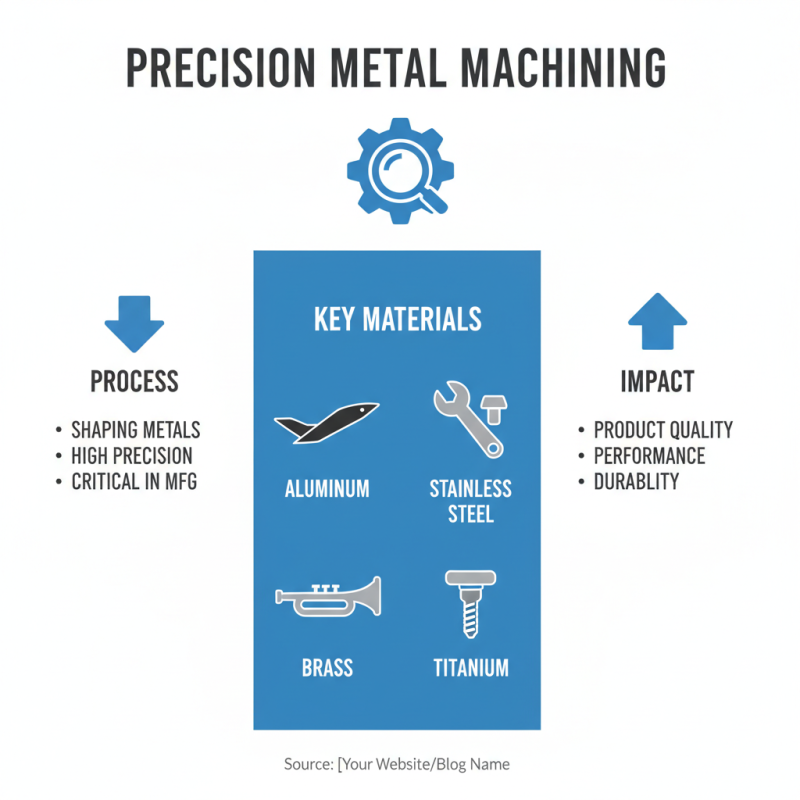

Precision metal machining is a critical process in manufacturing. It involves shaping metals with high accuracy. The materials used significantly impact the quality of the end product. Common materials include aluminum, stainless steel, brass, and titanium.

Aluminum is lightweight and easily machinable. It is often used in aerospace and automotive industries. Stainless steel, on the other hand, is known for its strength and corrosion resistance. It's a preferred choice in medical equipment and food processing.

Brass stands out for its excellent machinability and conductivity. However, it can be more expensive than other options. Titanium is a strong yet lightweight material. It's challenging to machine but ideal for high-performance applications.

**Tips:** When selecting a material, consider the end-use. Always think about the machining process involved. Each material will respond differently to various tools and techniques. Remember, not every material will meet every requirement. Research and test to find what works best for your projects.

Precision metal machining is vital in various industries. Its applications span aerospace, automotive, and medical sectors. According to a recent report by MarketsandMarkets, the global precision machining market is projected to reach $114.22 billion by 2027. This growth reflects a rising demand for high-quality components that meet stringent specifications.

Aerospace companies use precision machining for critical parts. Components like turbine blades require exact dimensions to ensure performance and safety. Similarly, the automotive industry relies on precision machining for engine components that must withstand extreme conditions. However, precision machining is not without challenges. Maintaining tight tolerances can lead to increased waste if not managed properly. Quality control issues can arise during production, leading to costly reworks.

In the medical field, precision machining plays a crucial role in creating surgical instruments and implants. These components must be manufactured with the utmost accuracy to ensure patient safety. While the benefits are clear, businesses also face potential setbacks. The need for skilled labor can create hiring obstacles. Thus, while precision machining offers immense benefits, it requires careful planning and execution to avoid pitfalls.

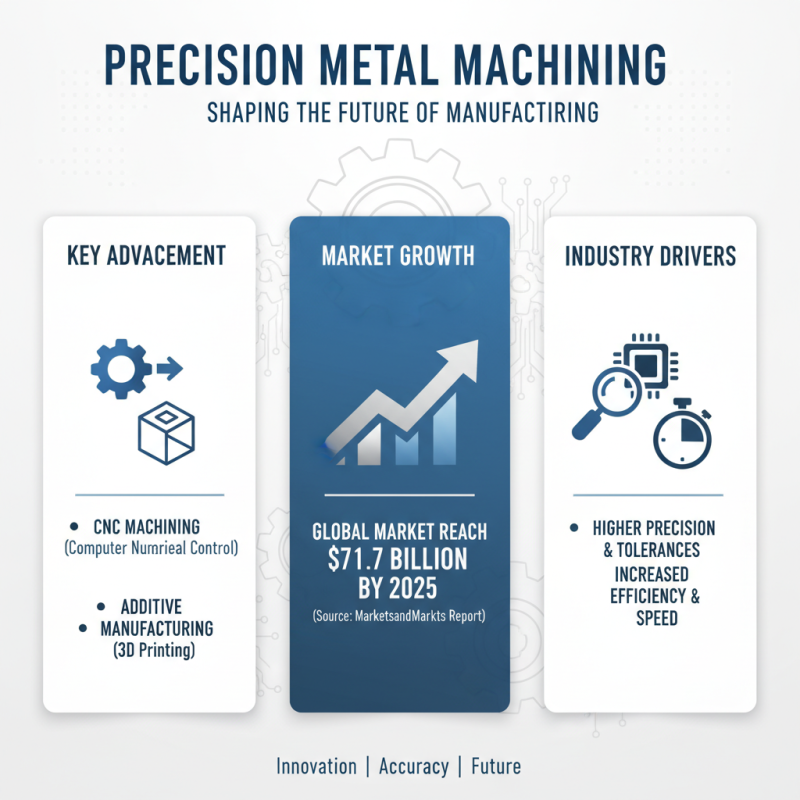

Precision metal machining has witnessed significant advancements in recent years. Techniques like CNC machining and additive manufacturing are shaping the landscape. According to a report by MarketsandMarkets, the global precision machining market is projected to reach $71.7 billion by 2025. This surge reflects the industry's need for higher precision and efficiency.

One emerging trend is automation. Robotics are now frequently used in machining processes. They can enhance productivity and reduce errors. Yet, reliance on automation can lead to skills gaps. Technician training must keep pace with technological advancements. Another noteworthy innovation is the integration of AI in machining. AI algorithms improve accuracy and efficiency but raise questions about job security.

Sustainability is also a pressing concern. Eco-friendly practices are becoming crucial in machining. The use of biodegradable coolants and recycling metals can minimize waste. However, the initial investment for sustainable technologies may deter smaller companies. Balancing innovation and cost will remain a challenge for many in the industry. These developments highlight the ongoing evolution of precision metal machining while showcasing areas in need of improvement.