+86 180 0293 5268

+86 180 0293 5268

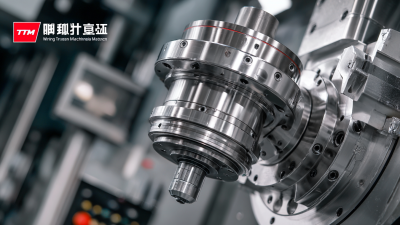

In today's fast-paced industrial landscape, the demand for high-quality components has never been greater. Precision Metal Machining stands at the forefront of this evolution, serving as a crucial technique for manufacturers striving to enhance performance and drive efficiency in their operations. With advancements in technology and engineering methods, the precision machining sector offers a plethora of techniques tailored to meet specific requirements, thereby ensuring that products not only meet but exceed industry standards.

This article delves into the Top 10 Precision Metal Machining Techniques that promise optimal performance for various applications. By exploring each method in detail, we aim to highlight the unique advantages and considerations associated with them, enabling manufacturers to make informed decisions. Whether it's achieving intricate designs, improving tolerances, or optimizing production times, understanding these precision machining techniques is essential for any organization looking to thrive in a competitive market. Join us as we journey through the essential strategies that elevate Precision Metal Machining to new heights and empower businesses to excel.

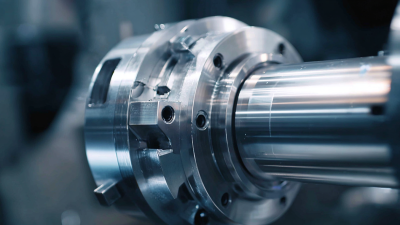

Precision metal machining is a critical aspect of modern manufacturing, enabling the production of intricate components with exceptional accuracy. Among the various techniques employed, methods such as CNC machining, electrical discharge machining (EDM), and laser cutting stand out for their ability to achieve tight tolerances and high-quality finishes. CNC machining utilizes computer-controlled tools to create parts that conform closely to design specifications, ensuring consistent results across large production runs. This technique is particularly favored for its versatility, allowing for complex geometries and rapid adjustments.

In addition to CNC machining, EDM is renowned for its precision in hard metals that are difficult to machine using traditional methods. By using electrical discharges to erode material, EDM is capable of producing intricate shapes and fine details with minimal thermal distortion. Laser cutting also enhances accuracy by delivering focused energy to the material, allowing for clean cuts with minimal kerf loss. These techniques, among others, contribute significantly to the manufacturing of precision components that meet demanding performance standards in industries ranging from aerospace to medical devices, where reliability and accuracy are paramount.

In the realm of high-performance engineering, innovative CNC machining strategies are becoming increasingly essential. The recent advancements, such as AI-powered efficiency and sustainability features, are transforming how manufacturers approach production. These next-generation CNC routers are designed not only for precision but also to minimize waste and energy consumption, aligning with modern sustainability goals in industrial processes.

As industries strive for greater performance, the integration of AI and data analytics plays a critical role. Advanced machine design trends are focusing on modularity and adaptability, allowing manufacturers to optimize their machining techniques based on real-time data. This shift enables businesses to respond rapidly to changing market demands while enhancing the precision and quality of their outputs, ensuring a competitive edge in the evolving landscape of manufacturing.

The realm of precision metal fabrication is rapidly evolving, largely driven by advanced tooling methods that enhance accuracy and efficiency. Businesses are increasingly investing in cutting-edge equipment to streamline their operations and maintain a competitive edge. The integration of smart technologies, such as CNC machines, is transforming shop floor layouts, allowing for automated processes that reduce human error and improve productivity. As companies adapt these tools, they pave the way for innovations that address the unique challenges of modern manufacturing demands.

Furthermore, the utilization of additive manufacturing techniques in the production of cutting tools exemplifies the industry's shift towards more versatile and sophisticated approaches. This method not only optimizes material usage but also enables the creation of complex geometries that traditional methods cannot achieve. As the North American metal fabrication market continues to expand, driven by a projected CAGR of 5.75% through 2033, the focus on advanced tooling will remain paramount. Companies that embrace these advancements are poised to enhance their operational efficiencies and foster long-term client relationships in a competitive landscape.

The landscape of precision metal machining is undergoing a significant transformation driven by emerging technologies. According to a report by Mordor Intelligence, the global precision machining market is projected to reach $32.8 billion by 2026, growing at a CAGR of around 7.5%. This growth is largely attributed to advances in automation, which are revolutionizing traditional machining methods. Technologies such as robotics and CNC systems are optimizing production efficiency and minimizing waste, allowing manufacturers to meet rising demand with higher quality outputs.

In addition, the integration of additive manufacturing with traditional machining techniques is enhancing flexibility and reducing lead times. A study from Deloitte highlights that 25% of manufacturers are leveraging some form of additive manufacturing to complement their machining processes. This hybrid approach not only enables the production of complex geometries but also supports sustainability efforts by reducing material usage. As these innovations continue to evolve, they are poised to yield substantial improvements in machining efficiency, driving the industry towards more sustainable and cost-effective practices.

This chart illustrates the effectiveness of various precision metal machining techniques in terms of their efficiency and application in modern manufacturing processes.

In the realm of precision metal machining, adherence to quality control best practices is paramount for achieving optimal performance and ensuring product reliability. According to the National Institute of Standards and Technology (NIST), implementing rigorous quality control measures can reduce manufacturing defects by up to 75%. This not only enhances product safety but also significantly lowers operational costs in the long run. Techniques such as Statistical Process Control (SPC) and Total Quality Management (TQM) contribute to real-time monitoring of machining processes, allowing for immediate adjustments and minimizing variations that could compromise quality.

Moreover, incorporating advanced technologies like Computer Numerical Control (CNC) machining and automated inspection systems further elevates the effectiveness of quality control. A report by the Association for Manufacturing Technology (AMT) indicates that manufacturing companies utilizing CNC technology paired with automated quality checks have reported a 30% increase in production efficiency. These technologies facilitate precise measurements and reduce human error, resulting in consistent product quality that meets industry standards. By fostering a culture of continuous improvement and leveraging real-time data, manufacturers can ensure that their precision machining processes deliver not only accuracy but also enhanced performance outcomes.

| Technique | Description | Best Practices | Quality Control Methods |

|---|---|---|---|

| CNC Machining | Computer Numerical Control machining for high precision tasks. | Regular calibration of machines. | In-process gauging and inspections. |

| EDM (Electrical Discharge Machining) | Utilizes electrical discharges to shape metal. | Optimize electrode wear rates. | Voltage and current monitoring. |

| Laser Cutting | High precision cutting using focused laser beams. | Maintain beam focus & power levels. | Edge quality inspection and measurement. |

| 3D Printing | Layer-by-layer addition of material for precision parts. | Use of high-resolution printers. | Dimensional accuracy testing. |

| Hydroforming | Forming with fluid pressure for complex shapes. | Optimal pressure control. | Material strain analysis. |

| Milling | Cutting material with rotary cutters. | Selection of appropriate cutting speeds. | Use of quality assurance checks. |

| Turning | Rotating a workpiece against a cutting tool. | Tool life monitoring and replacement. | Post-machining measurements. |

| Grinding | Using abrasives to achieve smooth finishes. | Regular wheel dressing. | Micron-level precision checks. |

| Sheet Metal Fabrication | Processes including cutting, bending, and assembling sheets. | Control material quality. | Dimensional checks and fit tests. |