+86 180 0293 5268

+86 180 0293 5268

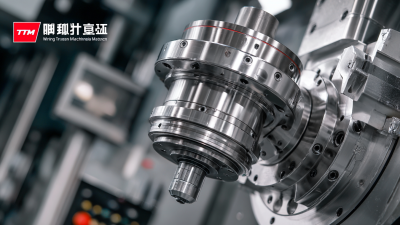

The landscape of modern manufacturing technologies is increasingly shaped by the pivotal role of Precision Parts Machining. This advanced manufacturing process is essential for producing components with exact specifications and minimal tolerances, directly impacting the efficiency and effectiveness of production across various industries. According to a report by Smithers Pira, the global precision machining market is expected to reach $60 billion by 2025, driven by the rising demand for high-quality and customized parts in sectors such as aerospace, automotive, and medical device manufacturing. The adoption of precision machining techniques not only enhances product performance but also reduces waste and operational costs, making it a crucial element in the pursuit of lean manufacturing. As industries continue to evolve and technology advances, understanding the intricacies of Precision Parts Machining will be vital for manufacturers aiming to remain competitive in a highly dynamic marketplace.

Precision parts machining plays a pivotal role in modern manufacturing, primarily due to its significant impact on manufacturing efficiency. According to a study by the National Institute of Standards and Technology (NIST), precision machining improves productivity in manufacturing processes by up to 20%. This enhancement is primarily attributed to reduced waste, optimized material usage, and increased speed and accuracy during production. With rising demands for complex components across various sectors, including aerospace and automotive, the reliance on precision machining techniques has become essential to meet tight tolerances and intricate designs.

Furthermore, a report from Deloitte highlights that manufacturers leveraging precision parts machining technologies have seen a reduction in operational costs by nearly 15%. This is largely due to fewer errors leading to reworks, shorter cycle times, and improved product quality. As global competition intensifies, the ability to manufacture high-quality components efficiently gives companies a competitive edge. The integration of advanced machining technologies, such as computer numerical control (CNC) and additive manufacturing, further amplifies these benefits, driving innovation and sustainability in manufacturing processes. Thus, the importance of precision parts machining cannot be overstated, as it is crucial for achieving overall manufacturing efficiency in today’s fast-paced industrial landscape.

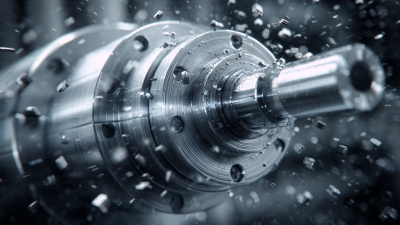

Precision parts machining plays a crucial role in modern manufacturing, driven by an array of advanced technologies that enhance production efficiency and product quality. Key advancements such as Computer Numerical Control (CNC) machining have revolutionized the manufacturing landscape, allowing for precise and consistent production of components like shafts, pins, and threaded elements. These technologies enable manufacturers to automate complex processes, dramatically reducing cycle times and minimizing human error, which is essential for meeting the increasing demands of the market.

Further fueling growth in the precision turned product manufacturing sector, projections indicate that the market size is expected to reach USD 196.11 billion by 2034. This demand is largely attributed to industries adopting lean manufacturing principles alongside sophisticated digital technologies. Integrating smart technologies into production systems fosters not only efficiency but also facilitates quality improvement across various sectors. As industries embrace these innovations, the significance of precision parts machining as a cornerstone of modern manufacturing continues to amplify, driving competitive advantage and sustainable growth.

| Technology | Description | Application Area | Advantages |

|---|---|---|---|

| CNC Machining | Computer Numerical Control machining allows for automated precision cutting and shaping of materials. | Aerospace, Automotive, Manufacturing | High precision, repeatability, and capability to produce complex shapes. |

| 3D Printing | Additive manufacturing technique that creates parts layer by layer from digital models. | Medical, Aerospace, Prototyping | Material efficiency, design flexibility, and rapid prototyping capabilities. |

| Electrical Discharge Machining (EDM) | A machining process that uses electrical discharges to cut materials. | Tooling, Aerospace, Automotive | Ability to cut hard materials and produce intricate designs. |

| Laser Cutting | A technology that uses a laser to cut materials for various manufacturing processes. | Sheet metal fabrication, Automotive, Aerospace | Precision and minimal thermal distortion of the material. |

| Milling Machines | Machines that use rotating cutters to remove material from a workpiece. | General Manufacturing, Aerospace, Automotive | Versatility and capability to shape a variety of materials. |

Precision parts machining has become increasingly relevant in modern manufacturing, particularly when evaluating the cost benefits over traditional methods. Unlike conventional subtractive manufacturing, which often involves significant material waste and longer lead times, precision machining utilizes advanced techniques to minimize waste and enhance efficiency. This shifts the focus towards more sustainable practices that can ultimately lead to cost reductions in the long run.

Recent trends in the additive manufacturing sector, particularly in metal 3D printing, illustrate this transition clearly. Additive manufacturing addresses many pain points of traditional processes by directly building parts layer-by-layer from digital models, significantly reducing both material costs and production timelines. As the technology matures, it becomes more cost-effective, challenging traditional machining methods by providing greater design flexibility and complexity at potentially lower costs. Such developments underscore the growing importance of precision machining technologies in creating a more adaptable and economical manufacturing landscape.

The landscape of precision parts machining is evolving rapidly, driven by advancements in technology and the increasing demand for higher reliability and efficiency in manufacturing. According to a report by MarketsandMarkets, the global precision machining market is projected to reach $88.7 billion by 2026, growing at a CAGR of 7.2%. This growth can be attributed to the incorporation of smart manufacturing technologies such as automation and the Internet of Things (IoT), which enhance the precision and quality of machined components.

Future trends in precision parts machining indicate a strong shift towards additive manufacturing and hybrid machining processes. A study by Statista predicts that the additive manufacturing sector could surpass $38 billion by 2026, highlighting a growing preference for technologies that allow for complex designs and reduced material waste. Moreover, integrating artificial intelligence (AI) and machine learning into machining processes is poised to improve predictive maintenance and process optimization, significantly impacting overall manufacturing excellence.

These innovations not only enhance productivity but also contribute to sustainability efforts within the industry, ensuring that precision parts machining remains a cornerstone of modern manufacturing practices.

Precision parts machining has emerged as a cornerstone of modern manufacturing, significantly enhancing product quality while minimizing waste. According to a report by the National Institute of Standards and Technology (NIST), the adoption of precision machining techniques can lead to a 30% reduction in material waste. This is achieved through advanced technologies such as CNC machining, which allows for tighter tolerances and more efficient use of materials. As a result, companies are not only improving the durability of their products but also adopting more sustainable practices that resonate with environmentally conscious consumers.

To further enhance product quality, manufacturers are increasingly leveraging real-time data analytics in precision machining processes. A recent survey by the Manufacturing Institute indicates that 67% of manufacturing leaders believe that implementing data-driven strategies has led to substantial improvements in product consistency and defect rates. This integration of technology enables manufacturers to execute corrective measures swiftly, ensuring that every component adheres to the highest standards.

**Tips:** To optimize your precision parts machining process, consider conducting regular maintenance on your equipment to prevent unexpected downtime. Additionally, investing in employee training on the latest machining technologies can significantly improve the skill set within your team, ultimately leading to better product quality.