+86 180 0293 5268

+86 180 0293 5268

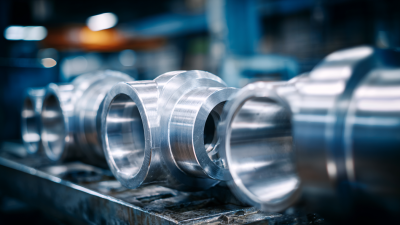

As industries endeavor to enhance operational efficiency and product quality, the adoption of high-performance Stainless Steel Casting Parts has emerged as a transformative solution. According to a recent report by the International Journal of Advanced Manufacturing Technology, the global market for stainless steel casting is projected to reach $20 billion by 2025, driven by demand in automotive, aerospace, and heavy machinery sectors. These advanced casting parts offer superior strength, corrosion resistance, and design flexibility, making them essential for modern manufacturing processes. Implementing stainless steel casting not only improves the durability and performance of industrial components but also contributes to significant cost savings and waste reduction. As manufacturers continue to innovate and seek ways to optimize their production lines, the role of stainless steel casting parts will become increasingly pivotal in shaping a more sustainable and efficient industrial landscape.

High performance stainless steel casting parts are transforming the manufacturing landscape by offering unique advantages that significantly enhance industrial efficiency. According to a report by MarketsandMarkets, the global stainless steel castings market is projected to reach USD 27.67 billion by 2026, growing at a CAGR of 5.3%. This growth is largely driven by the versatility and durability of stainless steel, making it an ideal choice for various applications in industries such as aerospace, automotive, and energy.

One of the key advantages of high performance stainless steel casting parts is their exceptional resistance to corrosion and wear, which contributes to longer service life and reduced maintenance costs. For instance, data from the American Institute of Steel Construction reveals that stainless steel components can last up to 50 years in harsh environments, compared to just a decade for traditional materials. Additionally, advances in casting technology have led to the production of parts that require less machining, thus minimizing waste and improving overall production efficiency. As manufacturers increasingly adopt these innovative materials, they not only improve operational performance but also support sustainability initiatives through reduced lifecycle environmental impacts.

Advanced manufacturing techniques have fundamentally transformed the production of stainless steel castings, driving improvements in efficiency and performance across various industries. Techniques such as precision casting, additive manufacturing, and digital simulation allow for the creation of complex geometries and intricate designs that were once difficult, if not impossible, to achieve. By utilizing these methods, manufacturers can minimize material waste and reduce lead times, leading to a more streamlined production process that meets the growing demands of modern industrial applications.

Moreover, the integration of automation and smart technology into the casting process enhances quality control and consistency in production. Real-time monitoring systems can ensure that each cast meets stringent specifications, thus reducing the likelihood of defects and the need for rework. This not only boosts productivity but also contributes to a safer working environment as risks associated with manual handling and unpredictable processes are minimized. As these advanced techniques continue to evolve, they promise to further revolutionize the capabilities and applications of stainless steel castings, paving the way for increased industrial efficiency.

The chart above illustrates the production efficiency of various stainless steel casting techniques. Advanced manufacturing methods like 3D printing and die casting show significant improvements in efficiency compared to traditional methods. This highlights the importance of adopting innovative approaches to enhance productivity in industrial manufacturing.

The economic impact of stainless steel casting on industrial production lines is profound, particularly in terms of cost efficiency and environmental performance. Stainless steel, known for its durability and resistance to corrosion, can significantly reduce maintenance costs and extend the lifespan of manufacturing components. As industries face rising pressures to lower their carbon footprints, the use of stainless steel casting presents a viable solution, demonstrating a lower life cycle cost compared to traditional materials. Its recyclability also contributes to minimizing waste and resource consumption in manufacturing processes.

Tips: When adopting stainless steel casting in industrial applications, consider conducting a life cycle assessment (LCA) to evaluate both environmental impacts and economic advantages. Additionally, integrating lightweight materials where applicable can complement the use of stainless steel, further enhancing energy efficiency during production and operation.

The steel industry is under scrutiny for its environmental implications, but advancements in stainless steel casting methods can help mitigate these issues. Innovative techniques are being explored to reduce greenhouse gas emissions associated with steel production. By shifting towards more sustainable practices and materials, companies can not only comply with regulations but also appeal to a growing market that prioritizes green manufacturing.

| Dimension | Value | Unit | Economic Impact |

|---|---|---|---|

| Cost Reduction | 15 | % | Increased Profit Margins |

| Durability Increase | 25 | % | Reduced Maintenance Costs |

| Production Speed | 20 | % Increase | Higher Output Efficiency |

| Waste Reduction | 30 | % | Lower Material Costs |

| Investment Return Rate | 18 | % | Enhanced Capital Efficiency |

The innovative applications of stainless steel castings are transforming various industries, driving efficiency and performance to new heights. As projected, the Steel Casting Market is expected to reach USD 42.18 billion by 2029, reflecting a robust demand for high-performance casting solutions across sectors. Stainless steel castings are recognized for their superior corrosion resistance and structural integrity, making them ideal for industries ranging from automotive to aerospace, where durability and precision are critical.

Moreover, the Metal Alloys Market is forecasted to escalate to USD 557.8 billion by 2035, with a notable CAGR of 4.5% between 2025 and 2035. This growth demonstrates the increasing reliance on advanced materials, including stainless steel alloys, to meet the evolving needs of manufacturing processes. As industries continue to seek lightweight and high-strength components, the adoption of stainless steel castings will play a vital role in enhancing productivity and innovation across diverse applications.

The future trends in stainless steel casting are expected to significantly influence industry standards, particularly in manufacturing efficiency. With advancements in technology, particularly in artificial intelligence, manufacturers are refining their processes to achieve higher performance and lower costs. The steel casting market is projected to grow substantially, driven by increasing construction activities and the relentless pursuit for innovation. As companies adopt cutting-edge methodologies, the impact on industrial efficiency will be profound, resulting in enhanced quality and sustainability of products.

The future trends in stainless steel casting are expected to significantly influence industry standards, particularly in manufacturing efficiency. With advancements in technology, particularly in artificial intelligence, manufacturers are refining their processes to achieve higher performance and lower costs. The steel casting market is projected to grow substantially, driven by increasing construction activities and the relentless pursuit for innovation. As companies adopt cutting-edge methodologies, the impact on industrial efficiency will be profound, resulting in enhanced quality and sustainability of products.

Tips: When exploring new technologies, consider how they can be integrated into existing production workflows to maximize efficiency. Evaluate suppliers that prioritize innovative practices, as they can help you stay ahead in a rapidly changing market. Additionally, keep an eye on regulatory changes that may set new industry standards, ensuring compliance while maintaining competitive advantage.

As we witness the evolution of stainless steel casting, it is important to stay informed about emerging trends and practices. By understanding the market dynamics, manufacturers can proactively adapt to these changes, positioning themselves as leaders in the industry. The embrace of AI-driven processes not only streamlines operations but also supports sustainable practices, enhancing the overall quality of industrial outputs.