+86 180 0293 5268

+86 180 0293 5268

Stainless Investment Casting has become a vital technique in various industries. It offers precision and durability for complex metal parts. According to industry expert John Smith, "Stainless Investment Casting allows for intricate designs without sacrificing strength." This method enables manufacturers to produce high-quality components.

Many companies have embraced Stainless Investment Casting due to its advantages. Its ability to create detailed geometries saves on machining costs. However, some challenges remain. The initial investment in molds can be significant and requires careful consideration. Additionally, not every type of stainless steel is suitable for this process.

Despite these challenges, the benefits of Stainless Investment Casting are clear. It improves product performance and extends service life. As industries push for innovative solutions, this casting method stands out. Yet, companies must continually assess their processes to ensure optimal results in a competitive landscape.

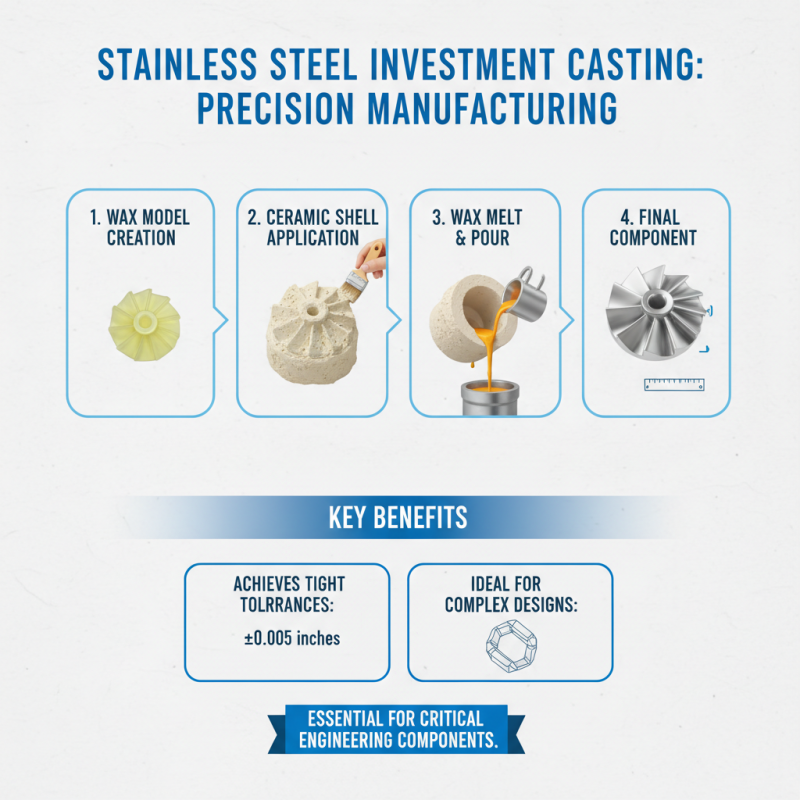

Stainless investment casting is a precise manufacturing process. It is essential in producing complex stainless steel components. The process involves creating a wax model, coating it in a ceramic shell, and melting the wax away. According to industry reports, this method can achieve tolerances as tight as ±0.005 inches. This allows for intricate designs that meet specific engineering requirement.

One key benefit is the high-quality surface finish it provides. Parts produced through this method often require little to no machining. This saves time and reduces costs. A study by the Investment Casting Institute noted that stainless investment casting can reduce production time by up to 30%. However, not all designs may suit this method. Complex geometries can lead to challenges such as trapped metal and defects.

Another aspect to consider is material properties. Stainless steel offers excellent corrosion resistance. It performs well in high-temperature environments. Yet, the casting process can introduce inconsistencies in properties. Some regions may have different microstructures, affecting durability. It is crucial to evaluate these factors when choosing this method for production.

Stainless investment casting is a specialized manufacturing process that offers high precision and intricate designs. The process begins with creating a wax pattern, which is then coated with ceramic. Once the ceramic hardens, the wax is melted away, leaving a mold for molten stainless steel. This method excels in producing complex shapes that meet tight tolerances.

One of the main advantages of stainless investment casting is its ability to minimize waste. According to the American Foundry Society, this process can reduce material waste by up to 90%. Additionally, it allows for excellent surface finishes, often requiring little to no machining. This efficiency can lead to lower production costs for businesses, making it a preferred choice in industries such as aerospace and medical devices.

Tips: Ensure your designs account for thermal expansion when casting. This can affect the final dimensions. Also, consider the alloy’s properties; different stainless steel grades can impact strength and corrosion resistance. Regular evaluation of the casting process is essential. It can reveal areas needing improvement, potentially leading to better product quality.

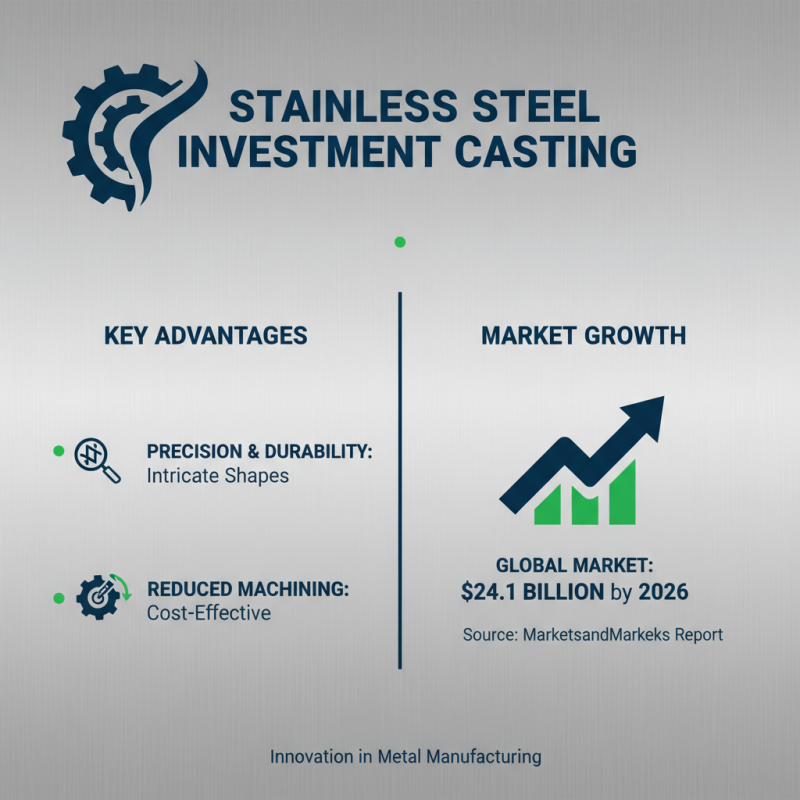

Stainless investment casting has revolutionized various industries by offering a unique blend of precision and durability. One of the main advantages is its ability to produce intricate shapes without the need for extensive machining. According to a report from MarketsandMarkets, the global investment casting market is expected to reach $24.1 billion by 2026, highlighting its growing significance.

The benefits also include material efficiency. Stainless steel provides excellent resistance to corrosion and high temperatures. Studies show that components made through stainless investment casting can withstand harsh environments, reducing maintenance costs by up to 30%. However, achieving the best results requires significant attention to detail throughout the production process.

Moreover, the casting process has some limitations. Quality control must be rigorous to avoid defects, which can compromise the final product. Potential issues include shrinkage or gas entrapments, leading to a need for constant monitoring. While the technology has advanced, challenges remain in balancing cost and quality. This reflects an ongoing conversation in the industry about optimizing processes.

Stainless investment casting boasts significant applications across various industries. The aerospace sector heavily relies on this process for producing critical components. According to a recent report, up to 80% of new aircraft engines use cast parts. These components benefit from high strength and reduced weight, essential for improving fuel efficiency.

In the medical field, stainless investment casting ensures precision and reliability. Surgical instruments, such as complex clamps and guides, are often made using this technique. A study indicated that the global market for stainless steel medical devices is projected to reach $17 billion by 2026. This growth showcases the increasing demand for high-quality cast items.

The automotive industry also utilizes stainless investment casting. It allows for the creation of intricate designs that conventional methods struggle with. However, challenges persist. For instance, achieving consistent quality can be difficult, and residual stresses must be managed properly. Innovating techniques could help address these issues and enhance output quality for various applications.

Stainless investment casting stands out in various manufacturing processes. This method excels in precision and surface finish. According to a report by MarketsandMarkets, the global investment casting market is projected to reach $20 billion by 2025. This growth reflects its advantages over traditional casting methods.

When compared with sand casting, stainless investment casting offers finer tolerances and less material waste. Sand casting often has rough surfaces. Investment casting, on the other hand, typically achieves a smoother finish, reducing post-processing needs. Yet, this precision comes with trade-offs. The initial tooling costs can be high, making it less ideal for one-off production runs.

Die casting allows for faster production, yet it might compromise on detail. For complex designs, investment casting remains superior. However, complexity can increase the production time. As industries evolve, process improvement must continually assess cost versus benefits. Companies need to find the right balance between precision and expense.