+86 180 0293 5268

+86 180 0293 5268

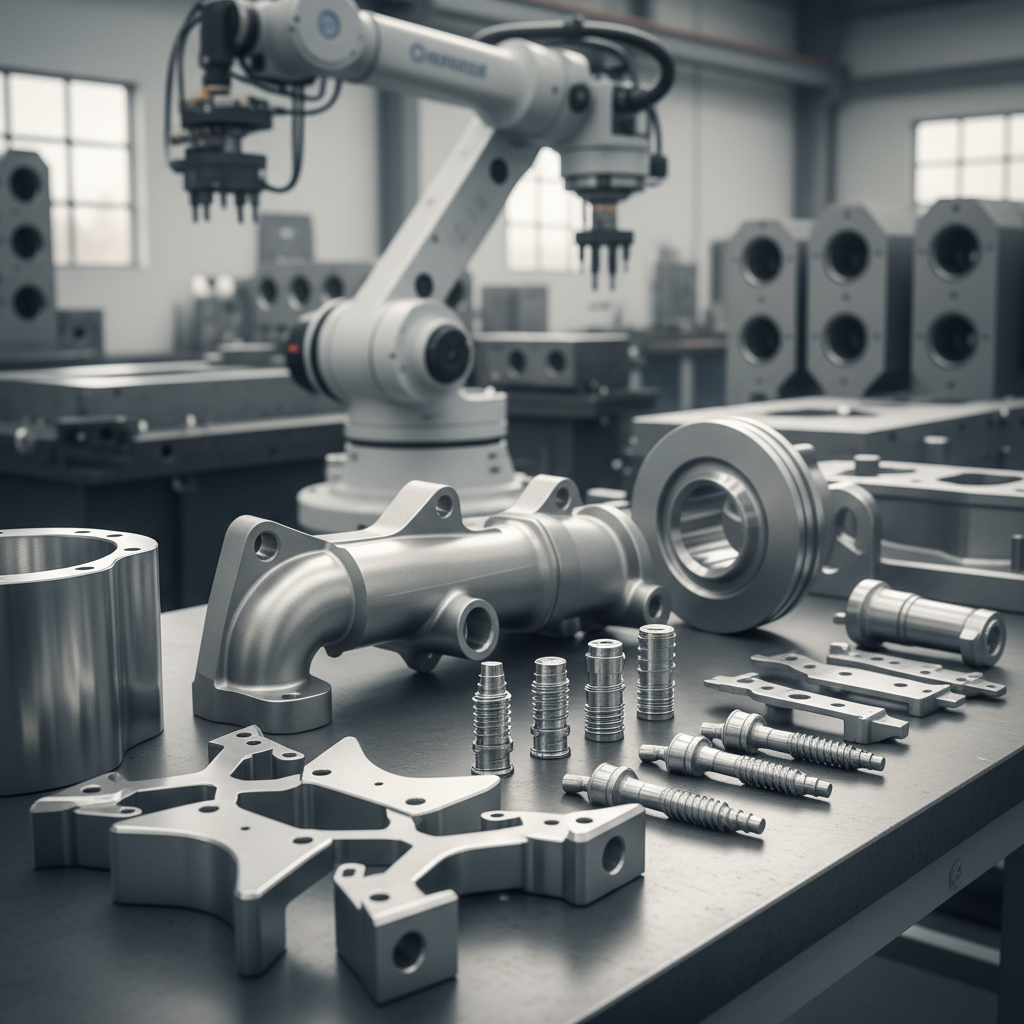

Stainless Investment Casting has emerged as a pivotal manufacturing process in various industries, known for its ability to produce complex shapes with high precision and excellent surface finishes. According to a recent market analysis by Smithers Pira, the global investment casting market is projected to reach $22.7 billion by 2026, showcasing a substantial annual growth rate. This growth is driven by the increasing demand for lightweight and durable materials, particularly in aerospace, automotive, and medical sectors, where stainless steel components are essential due to their corrosion resistance and mechanical properties.

The method of Stainless Investment Casting offers numerous benefits over traditional casting techniques, including reduced material waste and enhanced performance characteristics. A report from MarketsandMarkets highlights that the stainless steel casting segment alone is anticipated to grow significantly, fueled by innovations in manufacturing technology and an expanding application base. With applications ranging from intricate aerospace components to durable medical devices, the versatility and efficiency of Stainless Investment Casting position it as a preferred choice among engineers and manufacturers alike, ensuring that it remains at the forefront of modern manufacturing solutions.

Stainless investment casting is a sophisticated manufacturing process that allows for the creation of complex metal components with high precision. This method involves pouring molten stainless steel into a meticulously designed mold, which is often made from a wax pattern that is later removed by heating. The resulting cast parts exhibit excellent mechanical properties, making them suitable for various industries, including aerospace, automotive, and medical sectors. The advantages of stainless investment casting extend beyond precision; the process also allows for a significant reduction in material waste and the ability to produce intricate geometries that traditional machining methods may struggle to achieve.

The global steel casting market is experiencing noteworthy growth, driven by increasing demand for durable and high-strength materials. According to market analysis, investment casting is expected to play a crucial role in this expansion, with projections indicating a market reach of USD 32.3 billion by 2035. As industries continue to prioritize efficiency and sustainability, stainless investment casting stands out as a pivotal technology that not only meets these demands but also supports emerging innovations in product design and production methodologies.

Stainless investment casting is a precision manufacturing process that offers several key advantages. One primary benefit is the ability to produce complex geometries with a high level of detail. This method allows for intricate designs that might be difficult or impossible to achieve with traditional casting techniques. As a result, engineers and designers can optimize their components for performance without compromising on quality.

Another significant advantage of stainless investment casting is its excellent surface finish. The process typically requires minimal machining, which can lead to cost savings and faster production times. Additionally, the dimensional accuracy achieved through investment casting ensures that parts fit together correctly in assembly, which enhances the overall reliability of the final products. This precision makes it especially useful in high-demand industries, such as aerospace and medical devices, where the performance and safety of components are critical.

| Dimension | Description | Benefits | Applications |

|---|---|---|---|

| Material Quality | High-quality stainless steel alloys | Resistant to corrosion and extreme temperatures | Aerospace, automotive components |

| Precision | High accuracy and intricate designs | Reduces need for extensive machining | Medical devices, tooling |

| Manufacturing Process | Investment casting method | Efficient production of complex shapes | Industrial machinery, pumps |

| Finishing Options | Various surface finishing techniques | Enhances aesthetic and functional properties | Consumer products, architecture |

| Cost Efficiency | Reduction in material waste | Lower overall production costs | Construction, electronic housing |

Stainless investment casting has become an essential manufacturing process in various industries due to its ability to produce complex shapes with high precision and superior surface quality. The applications of stainless investment casting are particularly prominent in sectors such as aerospace, automotive, medical devices, and food processing. In aerospace, for instance, cast components made from stainless steel are critical for parts that require high strength and resistance to extreme temperatures. Similarly, in the automotive industry, we see a growing demand for lightweight and durable castings that contribute to better fuel efficiency and performance.

Tips: When considering stainless investment casting for your projects, think about the design intricacies that can be achieved with this process. It’s crucial to work closely with engineers to optimize the designs for casting, ensuring that you leverage the benefits of this technology fully.

In the medical field, precision is paramount; stainless investment castings play a vital role in the manufacturing of surgical instruments and implants. The cleanliness and bio-compatibility of stainless steel are also key factors that make it an ideal choice for medical applications. By understanding the specific requirements of each industry, businesses can better tailor their casting solutions to meet the market demand effectively.

Stainless investment casting is a specialized manufacturing process that offers several advantages over traditional methods like machining and sand casting. It provides greater dimensional accuracy and a smoother surface finish, making it ideal for complex geometries and intricate designs. Unlike sand casting, which can lead to rough surfaces and less precise dimensions, stainless investment casting minimizes material waste, improving overall efficiency.

The ability to produce highly detailed components makes this method invaluable in industries such as aerospace, automotive, and medical devices.

Tips for optimizing your investment casting process include investing in high-quality patterns and molds, which can significantly enhance the final product's accuracy and finish. Additionally, consider collaborating with experienced foundries that specialize in stainless investment casting to leverage their expertise, ensuring the best practices are applied throughout the manufacturing phase. Lastly, ensure that your design accounts for the specific characteristics of stainless steel, such as its thermal expansion and cooling properties, to achieve optimal results.

When comparing stainless investment casting with other manufacturing methods, it's essential to highlight the flexibility it offers in terms of design complexity. While methods like forging may excel in strength, they often limit design options. Stainless investment casting, on the other hand, can accommodate more intricate shapes and thin-walled sections without requiring extensive post-processing. This versatility makes it a preferred choice for manufacturers looking to balance performance with aesthetic appeal.

In recent years, stainless investment casting has seen significant advancements driven by emerging technologies and industry demands. The push towards increased efficiency and superior product quality has led to innovations in casting techniques, ranging from the integration of advanced alloy compositions to the adoption of automation in production processes. These enhancements not only improve the mechanical properties of cast products but also optimize the overall manufacturing workflow, thereby reducing lead times and costs.

Moreover, the market for stainless investment casting is projected to grow substantially, aligning with global trends in metal manufacturing. As industries increasingly prioritize sustainability and reduced material waste, innovative practices such as 3D printing and additive manufacturing are expected to play a pivotal role. These trends will facilitate the production of intricate designs and lightweight structures, further expanding the application scope of stainless investment castings in sectors like aerospace, automotive, and consumer goods. As a result, companies are strategically positioning themselves to leverage these trends, ensuring they remain competitive in a rapidly evolving marketplace.