+86 180 0293 5268

+86 180 0293 5268

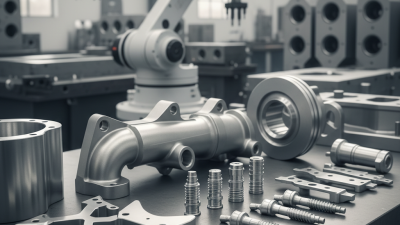

Stainless Investment Casting has become a cornerstone in modern manufacturing, offering a unique blend of precision and versatility. As per industry reports, the global market for investment casting is projected to reach USD 25.83 billion by 2027, showcasing a compound annual growth rate (CAGR) of 5.5% from 2020. This growth is driven by the increasing demand for high-quality, intricate metal components across sectors such as aerospace, automotive, and medical devices. Stainless Investment Casting allows for complex geometries and detailed designs that traditional manufacturing methods struggle to achieve, leading to reduced machining time and costs.

The benefits of Stainless Investment Casting extend beyond just aesthetic appeal; the process also enhances mechanical properties and surface finish, making it an ideal choice for critical applications. With stainless steel's inherent corrosion resistance and strength, components produced through this method can withstand extreme environments and loads. Reports indicate that stainless steel's usage in investment casting is gaining traction, with a notable increase in applications within the oil and gas, defense, and energy sectors, where durability and reliability are paramount. As industries continue to evolve, Stainless Investment Casting is expected to play an increasingly vital role in delivering innovative solutions tailored to specific operational challenges.

Stainless investment casting, also known as lost-wax casting, is a refined manufacturing process that allows for the production of complex geometries with exceptional accuracy and surface finish. This technique involves creating a wax model of the desired part, which is then coated in a ceramic shell. Once the shell is hardened, the wax is melted out, leaving a cavity that mimics the original model. Stainless steel is then poured into this cavity, producing a precise replica of the original wax pattern. The ability to achieve intricate designs and fine details makes stainless investment casting widely utilized in various industries.

The benefits of using stainless investment casting are numerous. One of the key advantages is the high dimensional accuracy it offers, which minimizes the need for extensive machining and reduces production time. Additionally, the smooth surface finish of the cast parts enhances the aesthetic qualities while also improving corrosion resistance, making them suitable for demanding environments. This process is particularly beneficial in sectors such as automotive, aerospace, and medical, where durability and precision are paramount. Its versatility allows for the development of components that are not only functional but also optimized for performance and longevity.

Stainless investment casting offers a multitude of key benefits, making it an increasingly popular choice across various industries. One of the primary advantages is its ability to produce highly complex and intricate shapes with excellent dimensional accuracy. This process allows for the manufacture of components that would be difficult or impossible to achieve with traditional manufacturing techniques. As a result, investment casting significantly reduces the need for secondary machining, leading to both time and cost savings in production.

Another notable benefit of stainless investment casting is its superior material properties. Stainless steel is inherently resistant to corrosion and oxidation, which is critical for applications in harsh environments. The use of this material not only enhances the durability and longevity of the parts produced but also ensures they maintain their mechanical integrity over time. This is especially valuable in industries like aerospace, automotive, and medical devices, where reliability and performance are paramount. Furthermore, stainless investment casting allows for greater design flexibility, enabling engineers to innovate and optimize designs without the constraints often associated with other manufacturing methods.

The process of stainless investment casting starts with the creation of a wax pattern, which is an exact replica of the desired part. This wax pattern is typically coated with a fine ceramic material, forming a shell around it. Once the shell is sufficiently thick, it is heated to melt and remove the wax, leaving a hollow ceramic mold. This method allows for intricate designs and precise dimensions, making it an ideal choice for complex stainless steel components.

Next, molten stainless steel is poured into the prepared mold. As the steel fills the cavity, it takes on the shape of the pattern with remarkable accuracy. After the metal cools and solidifies, the ceramic shell is broken away to reveal the cast part. This casting process not only maintains excellent surface finish and dimensional stability but also minimizes the need for extensive machining, which can further enhance production efficiency and reduce costs. Overall, stainless investment casting is a highly effective solution for producing high-strength, corrosion-resistant components used in various industries, including aerospace, automotive, and marine applications.

Stainless investment casting, also known as lost-wax casting, is a highly versatile manufacturing process that lends itself well to a variety of applications across numerous industries. One of the most common applications can be found in the aerospace sector, where components such as turbine blades, fuel nozzles, and housings are produced. The ability to create complex shapes with high precision allows manufacturers to achieve the demanding specifications required in aerospace technology, ultimately enhancing performance and efficiency.

Another significant application of stainless investment casting is in the medical field, particularly for surgical instruments and implants. The biocompatibility and corrosion resistance of stainless steel make it an ideal choice for medical devices that require both durability and hygiene standards. Components such as orthopedic implants and dental fixtures benefit from the accuracy of investment casting, ensuring they meet the strict tolerances necessary for successful patient outcomes.

In the automotive industry, stainless investment casting is utilized for producing critical engine components, brackets, and valve bodies. By leveraging the process, manufacturers can minimize weight while maximizing strength, leading to improved fuel efficiency and performance in vehicles. The process's ability to produce intricate designs while maintaining structural integrity positions stainless investment casting as a favored technique among engineers and manufacturers seeking innovative solutions.

In the world of metal casting, stainless investment casting has emerged as a highly efficient method due to its unique advantages over traditional casting processes. Unlike sand casting or die casting, stainless investment casting offers superior dimensional accuracy and surface finish, making it particularly suitable for intricate designs. Reports indicate that the tolerance levels achievable with investment casting can be as tight as ±0.3 mm, whereas sand casting typically fluctuates around ±1.5 mm. This precision not only enhances product quality but also significantly reduces the need for post-production machining, ultimately leading to cost savings.

Moreover, the material versatility offered by stainless investment casting is unparalleled. It allows for the use of a wide range of alloys, including super alloys and specialty alloys, which are essential for high-stress applications in industries such as aerospace and automotive. A comparative analysis reveals that while traditional methods may limit the types of materials that can be used, investment casting accommodates complex geometries and fine details that are often impossible to achieve through other methods. According to industry reports, the stainless investment casting market is projected to reach USD 22 billion by 2027, underlining the growing preference for this method as industries seek both quality and efficiency in their production processes.

| Casting Method | Material Compatibility | Dimensional Precision | Surface Finish | Production Rate | Cost Effectiveness |

|---|---|---|---|---|---|

| Stainless Investment Casting | Excellent for stainless steels and alloys | High precision ±0.1mm | Smooth finish; can be polished | Medium to high | Higher initial cost, lower per unit cost for large runs |

| Sand Casting | Good for various metals but not ideal for all alloys | Moderate precision ±0.5mm | Rough finish; requires machining for smoothness | High volume production | Low initial cost, economical for large parts |

| Die Casting | Ideal for non-ferrous metals | Very high precision ±0.01mm | Good finish but may need machining | High speed production rates | Moderate initial investment, low cost for high volumes |

| Centrifugal Casting | Works well for cylindrical parts using various metals | Moderate precision ±0.3mm | Medium finish; some machining may be required | Moderate production levels | Reducing cost for certain shapes over mass production |