+86 180 0293 5268

+86 180 0293 5268

Stainless Investment Casting is a sophisticated manufacturing process that combines precision and flexibility to produce complex metal parts with exceptional quality. This method, often referred to as lost-wax casting, enables manufacturers to create intricate shapes that would be challenging or impossible to achieve through traditional machining techniques. By utilizing a wax pattern and creating a ceramic shell around it, the final casting process allows for a high degree of detail and smooth surface finishes, making it ideal for various applications in industries such as aerospace, automotive, and medical.

The importance of Stainless Investment Casting lies not only in its ability to produce geometrically complex components but also in its efficiency and cost-effectiveness. Unlike other casting methods, this process minimizes material waste and enables the production of parts with tight tolerances. As the demand for high-performance and reliable components increases, understanding how Stainless Investment Casting works becomes crucial for manufacturers seeking to stay competitive in the fast-evolving industrial landscape. This article will explore the fundamental principles behind stainless investment casting, its advantages, and its role in modern manufacturing processes.

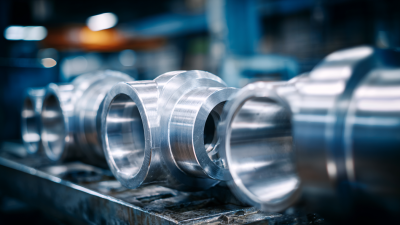

Stainless investment casting is a precise manufacturing process that enables the creation of complex metal components with excellent dimensional accuracy and surface finish. The process begins with the creation of a wax pattern, which is a replica of the final product. This wax pattern is coated with a ceramic material, typically through a series of dipping and hardening stages, forming a sturdy shell around the pattern. Once the ceramic shell is sufficiently hardened, the wax is melted away, leaving behind a mold cavity.

After the wax removal, molten stainless steel is poured into the cavity of the ceramic shell. The advantages of using stainless steel in investment casting include its corrosion resistance, high strength, and ability to withstand extreme temperatures. Once the molten steel solidifies, the ceramic shell is broken away to reveal the casted part. The final stages involve cleaning, machining, and finishing processes that refine the component, ensuring it meets the stringent specifications required for various applications across industries. This innovative method is particularly advantageous for producing intricate shapes that would be difficult or impossible to achieve through traditional casting techniques.

Stainless investment casting is a precision manufacturing process that relies heavily on the selection of appropriate materials to achieve high-quality results. The foremost material used in this method is stainless steel, which is favored for its corrosion resistance, strength, and versatility. Various grades of stainless steel, such as 304, 316, and Duplex stainless steel, are typically utilized, depending on the specific requirements of the final product. These materials can withstand extreme temperatures and provide excellent durability, making them suitable for a range of industrial applications, from aerospace to medical devices.

In addition to stainless steel, other materials, like ceramic and wax, are integral to the investment casting process. The initial mold is often created using a wax pattern, which is coated in a ceramic shell. This shell serves as the mold for the molten stainless steel, allowing for intricate designs and precision engineering. The selection of these materials is crucial, as they directly influence the casting's dimensional accuracy and surface finish. Properly chosen materials not only lead to enhanced performance of the finished products but also facilitate the overall efficiency of the manufacturing process.

The stainless investment casting procedure consists of several carefully orchestrated steps to create precision components from molten metal. The process begins with the creation of a wax pattern, which is an exact replica of the final part desired.

This wax pattern is then coated with a ceramic shell that is created by repeatedly dipping it in a liquid slurry and sprinkling it with sand. Once the ceramic shell hardens, the wax is melted and drained away, leaving behind a hollow mold.

Next, the mold is heated to further strengthen the ceramic shell and prepare it for the pouring of molten stainless steel. After reaching the required temperature, molten metal is poured into the mold cavity, filling it to create the desired shape. Once the metal cools and solidifies, the ceramic shell is broken away to reveal the cast part.

This method allows for exceptional detail and dimensional accuracy, making it ideal for intricate designs and high-performance applications in various industries.

Finally, additional finishing processes such as machining, surface treatment, or inspection may be performed to ensure that the final product meets the required specifications and quality standards. Each of these steps is crucial for maximizing the efficiency and precision of stainless investment casting, making it a preferred choice in modern manufacturing.

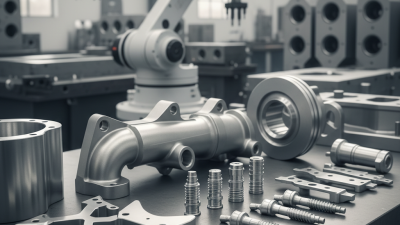

Stainless investment casting is increasingly favored across various industries due to its versatility and high precision. In the aerospace sector, stainless steel castings are crucial for manufacturing components that require exceptional strength and corrosion resistance while maintaining a lightweight profile. For example, turbine blades, exhaust systems, and other vital parts benefit from the superior mechanical properties of stainless investment casting, which ensures safety and reliability in flight.

In the medical industry, stainless investment casting plays a pivotal role in producing intricate components for surgical instruments and implants. The ability to create complex geometries with tight tolerances allows manufacturers to enhance functionality while adhering to stringent hygiene standards. Additionally, the automotive industry leverages stainless investment casting for producing durable and lightweight parts, improving fuel efficiency and performance in vehicles.

Tips: When considering stainless investment casting for your projects, it’s essential to collaborate closely with your manufacturer to ensure that the design specifications are optimized for casting. Also, consider the post-casting processes, such as machining and finishing, which can significantly affect the overall quality and performance of the final product. Always conduct thorough material selection to guarantee that the chosen stainless steel grade meets the specific requirements of your application.

Stainless investment casting is a versatile manufacturing process known for producing intricate parts with excellent tolerances and surface finishes. One of its primary advantages is the ability to create complex geometries that might be impossible to achieve with traditional machining methods. This process allows manufacturers to produce components with minimal waste, as the method uses precise molds and can incorporate multiple parts into a single casting, thus reducing assembly time and labor costs.

However, stainless investment casting also presents certain challenges. The initial cost of setting up molds and the production of the casting can be relatively high, especially for small batch sizes. Additionally, the process can be sensitive to material quality; impurities in the metal can lead to defects in the final product. Furthermore, achieving perfect dimensional accuracy can be challenging, as factors like shrinkage during cooling and the intricate design of the molds can affect the end result. Despite these challenges, the unique advantages make stainless investment casting a popular choice in industries ranging from aerospace to medical devices.