+86 180 0293 5268

+86 180 0293 5268

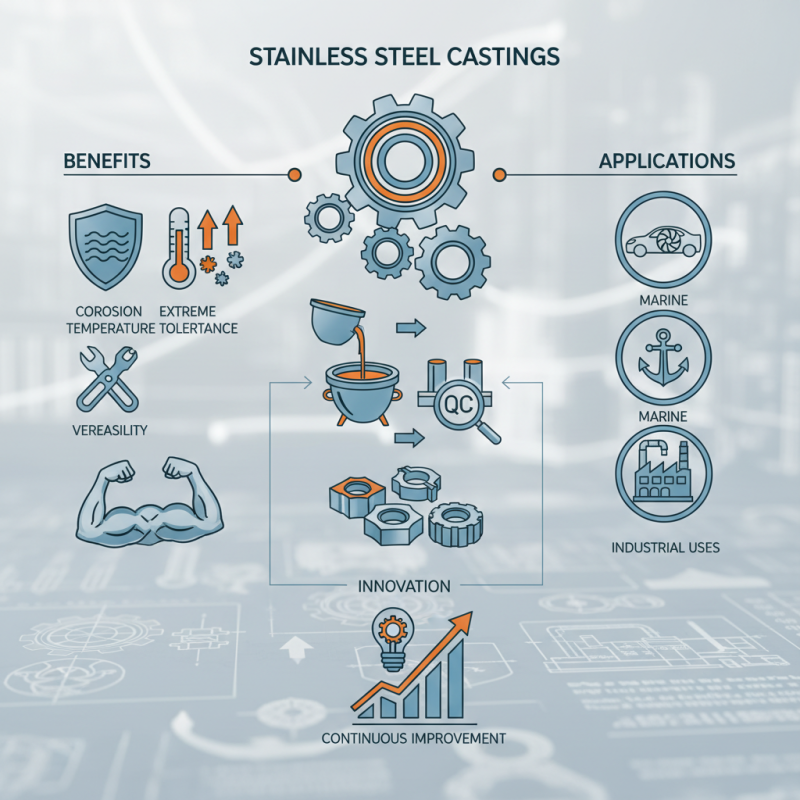

Stainless Steel Castings are a vital component in various industries, reflecting a blend of strength and versatility. John Smith, a leading expert in metal casting, states, "The adaptability of stainless steel castings makes them essential for modern applications." These castings resist corrosion and withstand extreme temperatures. They can be found in automotive, aerospace, and marine sectors.

However, the process of creating stainless steel castings is not without challenges. Quality control is paramount. A small defect can lead to significant failures in critical applications. This highlights the need for continuous improvement. We must analyze the casting techniques to enhance performance.

Understanding the benefits and applications of Stainless Steel Castings is crucial for manufacturers. With innovation comes responsibility. Each decision made in the casting process can impact entire industries. The future of stainless steel castings will depend on embracing new technologies while honoring established practices.

Stainless steel castings offer a range of benefits in various industrial applications. Their resistance to corrosion makes them ideal for environments exposed to moisture and chemicals. Factories often choose stainless steel for equipment that must endure harsh conditions. This durability extends the lifecycle of components, reducing the need for frequent replacements.

Another significant advantage is their ability to maintain structural integrity at high temperatures. In industries like aerospace and automotive, parts must withstand extremes. Stainless steel castings are often chosen for their strength-to-weight ratio. However, achieving consistent quality in these castings can be challenging. Variations in production techniques can lead to imperfections that may require adjustments.

Moreover, stainless steel is highly versatile. It can be molded into complex shapes, allowing for innovative designs. This flexibility often translates into improved performance. Yet, the initial costs can be higher than other materials, sometimes making budget planning difficult. Balancing performance with cost efficiency is always a consideration for industrial projects.

Stainless steel castings play a crucial role in many industries. Their durability and resistance to corrosion make them ideal for harsh environments. In the automotive sector, stainless steel castings are used in exhaust systems. These components withstand high temperatures and prevent rust.

In the food processing industry, these castings are essential. Equipment made from stainless steel maintains hygiene standards. With increasing regulations, the need for such materials is growing. They provide long-term solutions but come with challenges. The manufacturing process can be complex and costly.

Another significant application is in the marine industry. Stainless steel castings are commonly used for fixtures and fittings on ships. They resist the corrosive effects of saltwater. However, proper care and maintenance are still needed. Users must be aware of potential wear over time. Continuous evaluation helps in actual performance and longevity.

This chart illustrates the common applications of stainless steel castings across various industries, highlighting the percentage usage in sectors such as automotive, construction, food processing, and medical equipment.

Stainless steel castings offer unique benefits compared to other metal casting methods. They provide excellent corrosion resistance, which is crucial in harsh environments. According to a report by the American Foundry Society, stainless steel castings can withstand extreme temperatures, maintaining their properties better than aluminum or even carbon steels. This quality makes them ideal for the aerospace and chemical industries.

However, the production process of stainless steel castings can include challenges. The costs involved are generally higher than those for iron or aluminum castings. A recent study highlighted that stainless steel castings can be up to 20% more expensive than iron castings due to the complex techniques required. This leads some businesses to hesitate, fearing decreased competitiveness due to increased expenditure.

Despite these costs, the applications are diverse. Stainless steel is used in food processing, automotive parts, and medical devices. Its durability impacts long-term reliability. Some companies, however, may overlook the performance benefits when considering upfront costs. Balancing price with benefits is a dilemma many face when choosing casting methods. A further exploration of this balance is essential for optimizing production and staying innovative.

Stainless steel castings have numerous applications, from architecture to automotive. However, the quality of these castings largely depends on various factors. Key aspects include the composition of the alloy, melting processes, and environmental conditions during production. For instance, studies indicate that over 75% of defects in castings stem from improper melting techniques.

Controlling the alloy's composition is crucial. Even minuscule variations can lead to significant performance issues. A report from the American Institute of Steel Construction noted that nearly 60% of stainless steel failures could be traced back to subpar alloy formulation. This highlights the need for careful monitoring during the casting process.

Tips: Always conduct thorough inspections of raw materials. Regular checks can prevent inconsistencies in future products. Consider using advanced melting technologies. They can increase quality and reduce waste during production. Small changes make a big difference. Subpar practices can tarnish the reputation of even the best manufacturers.

Moreover, environmental factors like temperature and humidity can impact the final product. Maintaining a controlled environment may seem tedious, but it is essential. A 2022 industry report revealed that mishandling environmental conditions increased defect rates by up to 30%. This shows the importance of consistent practices in producing high-quality castings.

Maintaining stainless steel castings is crucial for longevity and performance. Regular cleaning is essential. Dirt and grime can corrode the surface over time. A simple mixture of mild detergent and water works well. Scrub gently with a soft cloth. For tougher stains, consider using a non-abrasive cleaner designed for stainless steel. The key is to avoid harsh chemicals that can damage the surface.

According to industry reports, over 60% of users neglect proper maintenance, leading to reduced lifespan. This oversight can result in costly repairs or replacements. Even though stainless steel is resistant to rust and tarnish, it is not entirely immune. Environmental factors like humidity and salty air can cause pitting. Regular inspections can help catch these issues early, making maintenance more manageable.

Keeping the castings dry is also essential. Water left to sit can lead to staining. If you notice any discoloration, address it promptly. Use a soft cloth to dry off surfaces after exposure to moisture. It's essential to develop a routine. While many believe stainless steel requires little care, neglecting it leads to unexpected challenges. Regular attention can enhance the durability and appearance of the castings significantly.