+86 180 0293 5268

+86 180 0293 5268

When selecting Stainless Steel Casting Parts, one must consider several critical factors. Industry expert John Smith emphasizes, "Quality in casting is not just a choice; it's a necessity." His perspective highlights the importance of quality assurance and proper material selection in this field.

Choosing the right Stainless Steel Casting Parts can be daunting. Various grades of stainless steel offer different benefits and applications. Selecting a type that withstands corrosion while fitting specific design criteria requires attention. A poorly chosen part may lead to costly failures in production. This choice reflects heavily on the final product's performance.

Additionally, understanding manufacturing processes for Stainless Steel Casting Parts is essential. One must be aware of different casting techniques and their implications on durability. Often, manufacturers overlook these details, resulting in subpar components. Engaging in thorough research and asking the right questions can prevent these mistakes. Quality, reliability, and performance are the ultimate goals in your selection process.

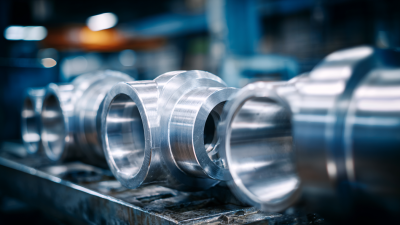

Stainless steel casting involves pouring molten stainless steel into a mold to create complex parts. This process allows for high precision and durability. It is widely used in various industries, including automotive, aerospace, and medical. Applications often require components that can withstand extreme temperatures and corrosive environments.

When selecting stainless steel casting parts, consider the specific application. Different grades of stainless steel suit different purposes. For example, 316 stainless steel resists corrosion better than 304. Evaluate which properties are essential for your needs.

Another tip is to assess the finish and tolerances of the castings. A smoother finish may be required for aesthetic purposes. However, a rough finish can sometimes save cost. Be cautious of the trade-offs. Inconsistent tolerances may lead to assembly issues and affect the overall performance.

Ultimately, clear communication with your supplier is vital. Discuss your requirements clearly to ensure they understand your expectations. This can avoid misunderstandings later. Being mindful of these factors will help you make an informed choice in stainless steel casting parts.

Choosing the right stainless steel casting parts can be challenging.

It's essential to consider several key factors. First, the type of stainless steel plays a crucial role. Different grades offer varying properties. You might want corrosion resistance, strength, or durability. Each application requires specific attributes.

Another factor to think about is the casting method. There are various techniques, including sand casting and investment casting. Each method has its advantages and drawbacks. The quality of the finish also varies between processes. You may find that some methods suit your needs better than others.

Finally, look closely at the supplier's reputation.

Quality control is vital in manufacturing. Some suppliers may cut corners, leading to defects. Always ask for samples or references. This helps you gauge the reliability of the parts. Never settle for less than what you require.

When selecting stainless steel casting parts, understanding material specifications and standards is crucial. The American Society for Testing and Materials (ASTM) recommends several grades of stainless steel suitable for various applications. For example, ASTM Austenitic grades like 304 and 316 offer excellent corrosion resistance. However, not all grades are created equal. It’s essential to assess the specific needs of your project.

Tip: Check the specification sheet of the stainless steel. Ensure it meets your project requirements. Poor adherence to these standards can lead to material failure. Recent studies suggest up to 30% of casting defects arise from improper material selection, impacting performance and longevity.

Material specifications directly influence the pricing and availability of casting parts. Research indicates that parts made from well-specified materials last longer and perform better, reducing long-term costs. While many suppliers claim compliance, it's wise to verify through certifications.

Tip: Always ask for test reports. This helps ensure that you receive high-quality stainless steel parts. There’s no room for assumptions in your sourcing process. Quality issues can be costly and time-consuming to address. Just remember, not all that glitters is gold; always analyze the fine print.

| Material Specification | Standard | Typical Applications | Corrosion Resistance |

|---|---|---|---|

| Austenitic Stainless Steel (e.g., 304, 316) | ASTM A743 | Food processing, Chemical tanks | Good |

| Ferritic Stainless Steel (e.g., 430) | ASTM A240 | Automotive trim, Appliances | Moderate |

| Duplex Stainless Steel (e.g., 2205) | ASTM A790 | Oil and gas, Marine | Excellent |

| Martensitic Stainless Steel (e.g., 410) | ASTM A276 | Cutlery, Pumps | Fair |

| Super Austenitic Stainless Steel (e.g., 904L) | ASTM A312 | Pharmaceuticals, Marine applications | Outstanding |

When selecting stainless steel casting parts, the manufacturer’s capabilities play a crucial role. Check if they have advanced machinery and technology. This can greatly impact the precision and efficiency of production. A well-equipped facility often indicates a commitment to quality. Look for certifications that reflect standards in manufacturing processes.

Quality assurance practices are essential as well. Inquire about their inspection methods. Regular quality checks minimize defects. If the manufacturer doesn't test their products thoroughly, the risks increase. Ask how they handle non-conformances. A transparent system shows they prioritize quality. It's not just about meeting specifications; it’s also about ongoing improvements.

Consider visiting the manufacturing site if possible. The environment can speak volumes about their operations. Are there signs of chaos or disorganization? This could reflect on the final product. Engage in conversations with the staff. Their knowledge and attitude may reveal the overall culture of the company. Quality is often a collective effort.

When selecting stainless steel casting parts, understanding cost versus value is crucial. Price alone does not reflect the quality or longevity of the product. Many buyers assume that a lower price means savings, but this can lead to costly mistakes. Inferior castings may rust or deform, necessitating replacements sooner than expected.

Investing in higher quality castings might seem expensive initially. However, consider the total cost of ownership. Durable parts can last much longer, reducing the need for frequent replacements. Moreover, high-quality stainless steel exhibits superior resistance to corrosion. This feature is particularly vital in demanding environments, such as marine or chemical applications.

It’s worth reflecting on your specific requirements and applications. Cheap castings may fulfill immediate needs but could compromise performance. Evaluate material specifications and supplier reputations. Sometimes, spending a little more upfront offers significant long-term benefits. Be wary of deals that seem too good to be true. They often are. Each decision you make shapes the overall success of your project.