+86 180 0293 5268

+86 180 0293 5268

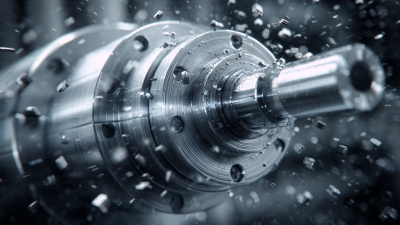

CNC machined parts play a vital role in modern manufacturing. The global CNC machining market is projected to reach $100 billion by 2025, highlighting its importance. Industry expert Dr. James Peterson notes, "Understanding CNC machined parts is crucial for innovation." Various components produced through CNC machining enhance precision and efficiency.

From aerospace to medical devices, these parts are tailored to meet stringent specifications. The accuracy of CNC machining drives advancements in technology. Yet, not all organizations fully leverage these innovations. Some still rely on outdated practices. Companies must reflect on their processes to stay competitive.

Choosing the right CNC machined part can determine success. Each component serves a specific purpose, impacting overall quality and performance. Understanding the top CNC machined parts is essential for manufacturers today. Gaining insight into this industry reshapes future production methods.

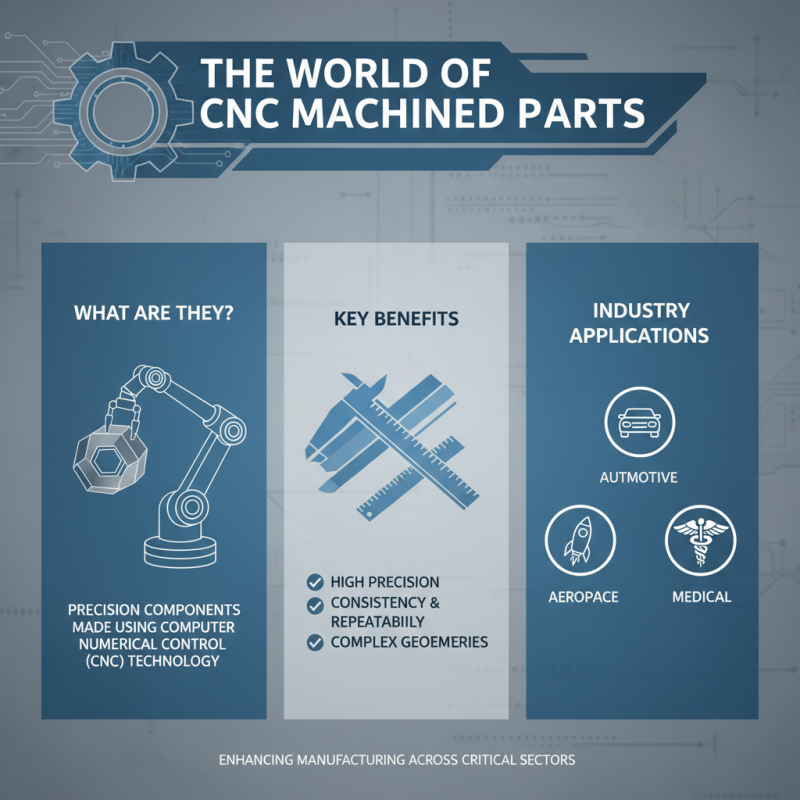

CNC machined parts play a crucial role in various industries today. These components are created using advanced computer numerical control technology. This process allows for high precision and consistency. It enhances the manufacturing of intricate parts. These parts are essential in automotive, aerospace, and medical applications.

CNC machining is versatile, producing items from simple shapes to complex designs. For instance, in the automotive sector, parts like brackets and housings are common. In aerospace, parts need to withstand high pressure and temperatures. Meanwhile, the medical field requires components that meet strict hygiene standards. However, the cost of CNC machining can be a barrier. Production runs that are too small may not be economical. Additionally, achieving the perfect finish requires careful calibration.

Understanding CNC machined parts can be overwhelming. A new designer might struggle with selecting materials or machining processes. Each decision impacts the final product’s quality and performance. More experience is needed to master the nuances of this technology. Mistakes may happen, leading to wasted material and time. Learning from these errors is essential for improvement.

CNC machining plays a critical role in modern manufacturing. This technology enables precise production of complex parts. Industries rely on it for efficiency and accuracy. From aerospace to automotive, CNC machining delivers quality. It reduces human error and speeds up production.

Tips: Focus on using high-quality materials. They enhance durability and performance. Regular maintenance of CNC machines is essential. It prevents unexpected downtimes. Knowledge of CAD software is also vital. It aids in precise design and execution.

The adaptability of CNC machining is impressive. It can create components of various sizes and shapes. However, some designs may still pose challenges. Technical limitations can arise, requiring creativity. There is often room for improvement in programming techniques. Continuous learning and adaptation are crucial to success.

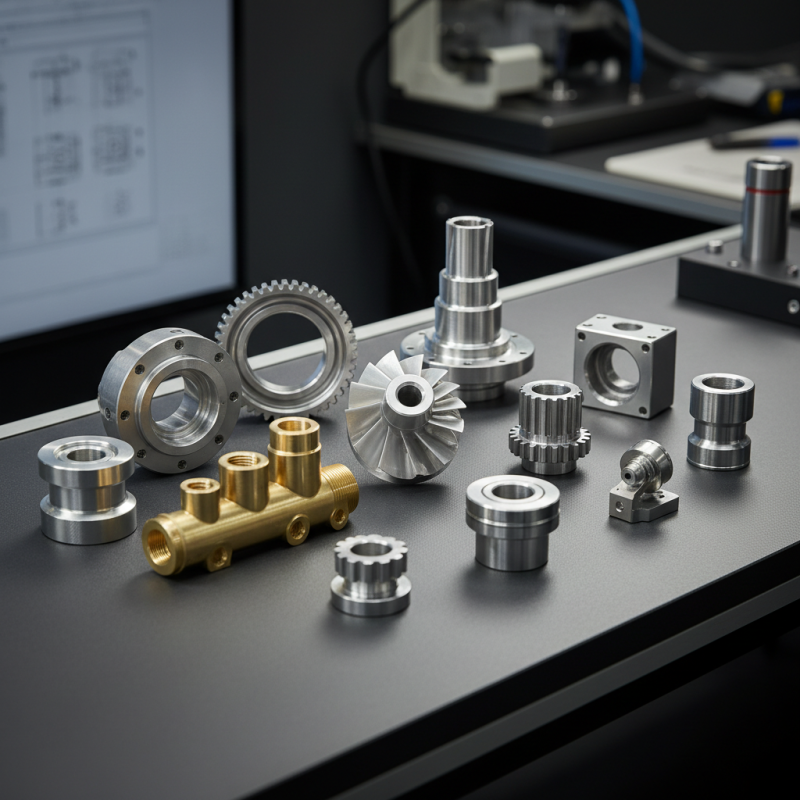

CNC machined parts are vital in various industries. They are made from several materials, each offering unique benefits. Aluminum is popular for its lightweight and high strength. It is easy to machine and has excellent corrosion resistance. Many industries rely on aluminum parts for their durability.

Steel is another common choice. It is renowned for its strength and versatility. However, steel can be heavier and more challenging to machine. This requires skilled labor and precise settings. Stainless steel, known for its resistance to rust, is also widely used. It might be more expensive but is perfect for harsh environments.

Plastics like nylon and polycarbonate are also essential. These materials can reduce weight significantly and are often used in consumer products. However, they may not provide the durability of metals. Selecting the right material involves considering factors like cost, strength, and application needs. Balancing these factors is often challenging but crucial for project success.

In CNC machining, precision tolerances are key to ensuring parts fit and operate correctly. The industry often adheres to standards like ISO 2768, which classifies tolerances into general, fine, and coarse categories. These help determine acceptable variations in dimensions. For example, a general tolerance could be ±0.5 mm for an 80 mm feature. This level of precision is vital, especially in sectors like aerospace and medical devices.

According to a recent report by CIMdata, over 75% of manufacturers cite tolerancing as a critical aspect of their production processes. However, achieving these tolerances can be challenging. Sometimes, parts may not meet specifications due to machine wear or setup errors. This can lead to increased costs and delays. Engineers must continuously review their practices to mitigate these issues.

Another study revealed that 30% of machined components failed to meet the specified tolerances in real-world conditions. This shortfall points to the need for better training and technology in the field. Unforeseen factors, such as temperature fluctuations and material inconsistencies, can cause deviations. Adjustments during the machining process are necessary but often overlooked. Hence, ongoing evaluation and optimization of tolerances should remain a priority.

| Part Name | Material | Precision Tolerance (mm) | Industry Applications |

|---|---|---|---|

| Bracket | Aluminum 6061 | ±0.01 | Aerospace, Automotive |

| Gear | Steel | ±0.005 | Industrial Machinery |

| Mounting Plate | Stainless Steel | ±0.02 | Electronics |

| Housing | Plastic (POM) | ±0.03 | Consumer Goods |

| Shaft | Carbon Steel | ±0.01 | Automotive, Robotics |

| Connector | Brass | ±0.005 | Telecommunications |

| Valve Body | Aluminum | ±0.02 | Hydraulics |

| Lid | Plastic (ABS) | ±0.03 | Home Appliances |

| Disc | Aluminum | ±0.01 | Musical Instruments |

| Collet | Tool Steel | ±0.005 | Machinery |

CNC machining plays a vital role in various industries. This technology allows for precise manufacturing of parts that meet strict operational requirements. Common CNC machined parts include brackets, housings, and gears. Each piece contributes significantly to the functionality of machines and devices.

Brackets provide structural support in automotive and aerospace applications. They must withstand heavy loads. Housings protect sensitive electronic components in consumer products. These parts often face challenges such as temperature fluctuations and moisture exposure. Gears are essential in transmitting motion and torque. They must be accurately cut to ensure seamless operation, reflecting the importance of precision.

Industries rely on these parts daily. However, the manufacturing process can lead to imperfections. Adjusting designs and machining parameters is crucial. Continuous improvement is necessary to achieve optimal functionality. Each machined part tells a story of innovation and necessity, highlighting the critical role of CNC technology in today’s world.