+86 180 0293 5268

+86 180 0293 5268

In the realm of manufacturing, CNC machining parts have emerged as a cornerstone for precision engineering and innovative design. With the continual advancement in technology, these components not only enhance the quality and efficiency of production processes but also open avenues for more complex geometries that traditional methods struggle to achieve. Whether you are a seasoned engineer or embarking on a new project, understanding the intricacies of CNC machining parts is essential in optimizing functionality and performance.

As we delve into the top 10 CNC machining parts, it is important to consider critical factors that influence their selection and application. Each part plays a vital role in the assembly and operation of various products, from intricate medical devices to robust automotive components. By examining the unique characteristics and requirements of different CNC machining parts, professionals can make informed decisions that elevate their projects from concept to completion. Ultimately, mastering these elements will ensure the delivery of high-quality results tailored to meet specific industry standards and customer needs.

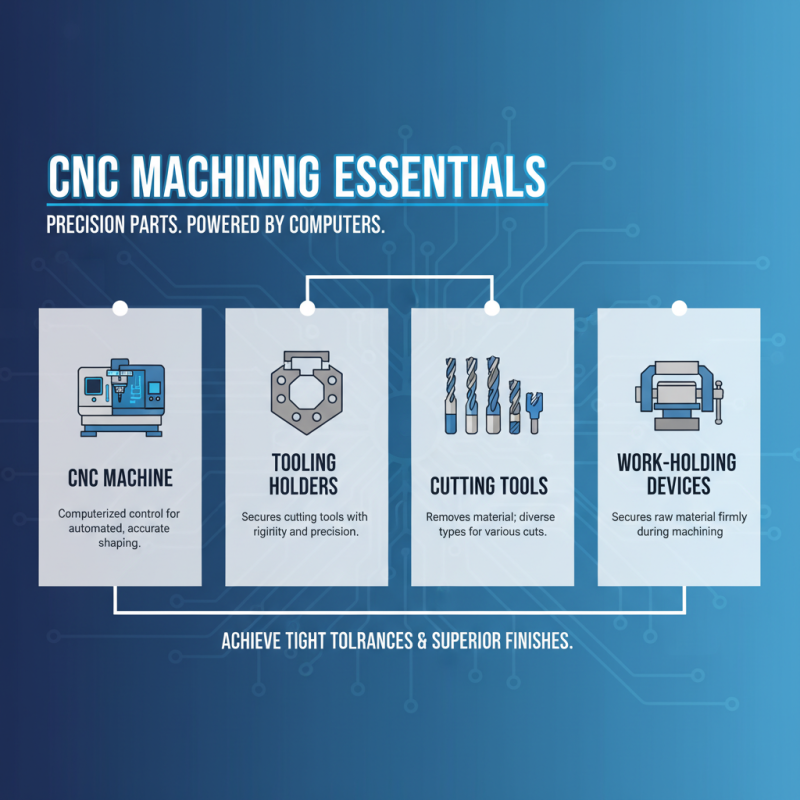

CNC machining is a pivotal process in manufacturing that produces precision parts for various industries. Understanding the different CNC machining parts and their functions is essential for anyone looking to undertake a project that involves this technology. At its core, CNC machining involves the use of computerized controls to drive cutting tools, shaping materials with high accuracy. Key components include the CNC machine itself, tooling holders, cutting tools, and work-holding devices. Each part plays a crucial role in achieving the desired tolerance and surface finish.

Tips: When selecting CNC machining parts, consider the material properties and the specific requirements of your project. For instance, the choice of cutting tool can greatly affect the machining process and the quality of the final product. Additionally, optimizing tool paths can minimize waste and enhance efficiency.

Another essential aspect is understanding the work-holding devices that secure your material during machining. Proper clamping is crucial to ensure stability and precision throughout the operation, preventing any movement that could compromise the accuracy of the finished part. Be sure to choose work-holding solutions that complement the size and shape of your components for optimal results.

When selecting CNC machining materials for your projects, one of the primary criteria is the specific application requirements. Different components may demand different material characteristics such as strength, weight, and thermal resistance. For example, if the part will be subjected to high stress or harsh environments, materials like aluminum or titanium might be preferred due to their superior strength-to-weight ratio and corrosion resistance. Understanding the mechanical properties needed for your particular use case helps in selecting the most suitable material.

Another crucial consideration is the machining capabilities of the selected material. Some materials are easier to machine and can achieve tighter tolerances, while others may pose challenges due to their hardness or brittleness. It's essential to evaluate how the material interacts with CNC machining processes, including tooling requirements and cycle times. Ultimately, the right choice of material will not only affect the final product's performance but also influence production efficiency and cost-effectiveness.

CNC machining is a critical process in manufacturing that significantly influences the quality of parts produced. The essential CNC machining processes, including milling, turning, and grinding, each have unique impacts on the final product's characteristics. For instance, milling allows for precise shaping of complex components by removing material using rotary cutters, which can lead to finer surface finishes and intricate designs. Properly executed milling can enhance both aesthetic qualities and functional performance, thus making it a top consideration when selecting CNC processes for a project.

Turning, another fundamental CNC technique, excels in producing cylindrical parts with high precision. The process involves rotating the workpiece against a cutting tool, ensuring that the resulting dimensions are incredibly accurate. This is vital for components that require tight tolerances, as small deviations can affect overall performance in applications such as automotive and aerospace industries. Moreover, grinding offers the ability to achieve exceptional surface finishes and fine tolerances, making it indispensable for parts that necessitate a high level of detail and smoothness. Understanding these processes and their implications on part quality is essential for successful project outcomes in any CNC machining endeavor.

| Part Name | Material Used | Machining Process | Tolerance Level | Surface Finish | Application |

|---|---|---|---|---|---|

| Gear | Steel | Milling | ±0.01 mm | Honed | Automotive |

| Bracket | Aluminum | Laser Cutting | ±0.05 mm | Anodized | Aerospace |

| Housing | Plastic | Injection Molding | ±0.1 mm | Smooth | Consumer Electronics |

| Plate | Stainless Steel | Water Jet Cutting | ±0.02 mm | Brushed | Food Industry |

| Valve | Brass | Turning | ±0.01 mm | Polished | Hydraulics |

| Connector | Aluminum Alloy | CNC Machining | ±0.02 mm | Anodized | Electronics |

| Pulley | Nylon | Injection Molding | ±0.05 mm | Smooth | Textiles |

| Bracket | Carbon Steel | Bending | ±0.1 mm | Galvanized | Construction |

| End Cap | PVC | CNC Machining | ±0.1 mm | Smooth | Piping |

| Sheave | Polycarbonate | CNC Milling | ±0.02 mm | Glossy | Bicycle Industry |

CNC machining parts are integral to a vast array of industries due to their precision and versatility. In the automotive sector, components such as engine blocks, brackets, and gears are frequently crafted using CNC technology. This method allows for tight tolerances and repeatability, ensuring that parts fit seamlessly and function optimally. Additionally, the aerospace industry relies heavily on CNC machining for producing lightweight yet durable components, including turbine blades and structural parts, which must meet stringent safety and performance standards.

In the medical field, CNC machining is critical for creating specialized tools, implants, and devices tailored to individual patient needs. Components like surgical instruments and prosthetics benefit from the intricacies of CNC machining, which enables the production of complex geometries that improve functionality and patient comfort. Furthermore, electronics manufacturing also utilizes CNC machining to produce detailed casings, connectors, and other components that require high precision and consistency, ultimately enhancing the overall reliability of electronic devices.

When considering CNC machining projects, budgeting is a crucial aspect that can significantly influence the overall success of your endeavor. According to a report by the Society of Manufacturing Engineers, approximately 40% of manufacturing costs are attributed to machining processes, highlighting the need for careful financial planning. Accurate budgeting starts with understanding the various factors that contribute to CNC costs, such as material selection, labor rates, and machine runtime. For instance, the choice of materials can dramatically affect both the tooling duration and material wastage, impacting your project's bottom line.

Tips: Always request detailed quotes from your chosen CNC machining suppliers. This will help you identify any hidden costs and ensure that your budget aligns with the project's specifications. Additionally, consider using simulation software to optimize designs beforehand, minimizing costly revisions in the machining phase.

It's essential to factor in additional costs associated with CNC machining, such as post-processing and finishing operations, which can account for up to 20% of total machining expenses. By estimating these ancillary costs, you can avoid unexpected budget overruns. Moreover, data from the American National Standards Institute indicates that effective project scheduling can lead to significant cost reductions—up to 15%—by enhancing production efficiency. By assessing these elements and incorporating them into your financial strategy, you can better navigate the complexities of CNC machining budgeting.