+86 180 0293 5268

+86 180 0293 5268

Investment casting is a critical process in manufacturing. It enables the production of intricate components with high precision. Many industries rely on this technique for their needs, making it vital to know the top investment casting foundries. John Smith, a leading expert in the investment casting field, once stated, "The right foundry makes all the difference in quality and service."

In today's competitive market, choosing the best investment casting foundry is essential for ensuring product integrity. Various factors come into play, including materials, technology, and expertise. Foundries vary widely. Some excel in standard parts, while others focus on custom solutions. This diversity can be confusing for manufacturers. Often, the best choice is not immediately clear.

Investment casting can sometimes be seen as outdated. However, modern techniques have evolved significantly. Some foundries are making strides, while others lag behind. It's crucial to evaluate each foundry's strengths and weaknesses. Investing time in research ensures better outcomes. After all, the right investment casting foundry can elevate a project to new heights.

Investment casting is a remarkable manufacturing process. It allows for precision and complex shapes that other methods may struggle to achieve. This technique involves creating a wax pattern, surrounding it with a ceramic shell, and then melting away the wax. The result is a durable mold that can cast metal with outstanding accuracy.

One key advantage of investment casting is its ability to produce intricate designs. This is especially useful in industries like aerospace and medical devices. However, the initial setup cost can be high. It often requires careful investment of time and resources in creating the molds. Yet, once the setup is complete, the benefits can be substantial.

Tips for success: Focus on quality during the wax pattern creation. A precise pattern leads to better final products. Also, stay flexible in your approach. Sometimes, designs need adjustments after initial trials. Don’t hesitate to refine your process to achieve the best results. Experimenting, even with small changes, can lead to fantastic improvements in the final casting quality.

| Rank | Location | Annual Production Capacity (Tons) | Key Industries Served | Certifications |

|---|---|---|---|---|

| 1 | USA | 5000 | Aerospace, Automotive | ISO 9001, AS9100 |

| 2 | Germany | 4500 | Medical, Industrial Equipment | ISO 13485 |

| 3 | China | 6000 | Automotive, Marine | ISO 9001 |

| 4 | India | 4000 | Aerospace, Oil & Gas | ISO 9001, API |

| 5 | Italy | 3500 | Machine Tool, Aerospace | ISO 9001, NADCAP |

| 6 | Japan | 3000 | Electronics, Automotive | ISO 9001 |

| 7 | Brazil | 2500 | Oil & Gas, Agriculture | ISO 9001 |

| 8 | Mexico | 2800 | Automotive, Industrial | ISO 9001 |

| 9 | Russia | 2200 | Defense, Aerospace | ISO 9001 |

| 10 | South Korea | 1500 | Consumer Electronics, Automotive | ISO 9001, IATF 16949 |

When selecting top investment casting foundries, several criteria come into play. First, consider the foundry's experience. A history of successful projects often indicates reliability and expertise. A foundry that has operated for several years typically shows stability in production methods.

Quality control is another crucial factor. Look for foundries that implement rigorous testing and inspection processes. This ensures that the final products meet specific standards. It’s valuable to check if they have certifications in quality assurance. Additionally, assessing their technological capabilities can indicate how well they adapt to modern manufacturing trends.

Communication plays a vital role too. A foundry should be transparent and responsive to queries. Delays in communication may reflect how they handle projects. Some foundries may excel at producing complex parts but struggle with timelines. This can lead to unexpected issues later. Engaging with their previous clients can offer insight into their reliability and service quality.

When exploring the world of investment casting foundries, it's essential to understand key players in the industry. Leading foundries offer a range of services, from prototypes to mass production. Many utilize advanced technologies to enhance precision and efficiency. Their capabilities vary, impacting both quality and delivery times.

Tips: Research each foundry's specialty. Some may focus on aerospace, while others cater to automotive. This helps align your needs with their expertise. Don't forget to check their production capacity. Capacity can affect project timelines significantly.

It's also worth noting the importance of communication with your chosen foundry. Clear dialogue can uncover potential challenges and solutions. Sometimes, misunderstandings arise about what is feasible. This can lead to delays or costly errors. Addressing these issues early can save time and resources.

Finding the right investment casting foundry is critical. Look beyond just price; consider quality and reliability. Reflect on each foundry's past projects. Customer testimonials can provide insight into their performance.

The investment casting industry is seeing groundbreaking innovations. New materials are being developed to enhance strength and reduce weight. For instance, advanced alloys are now being used, allowing for higher performance in critical applications. In fact, recent reports indicate a projected growth of 11% annually in the global market, driven largely by aerospace and automotive demands.

3D printing technology is also making waves. It changes how patterns are produced, making the process faster and more cost-effective. A study from the American Foundry Society highlights that companies using 3D-printed patterns can reduce lead times by up to 60%. However, not all foundries have adopted these innovations, leading to a gap in operational efficiency.

Data analytics tools are being utilized to optimize production processes. These tools help in monitoring quality control, yet not every foundry is leveraging this advantage. Some still rely on traditional methods, risking higher costs and longer turnaround times. As the industry evolves, the challenge remains: to fully embrace technological advancements and remain competitive.

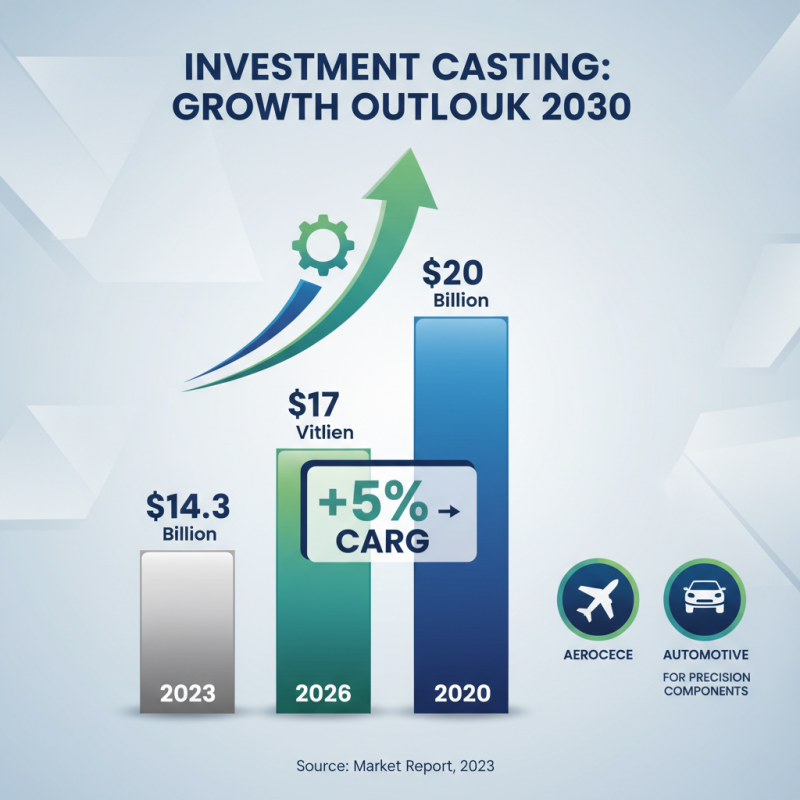

The investment casting industry is poised for significant growth in the coming years. According to a recent market report, the global market size for investment casting is expected to reach $20 billion by 2030. This reflects a compound annual growth rate (CAGR) of approximately 5% from 2023 to 2030. Factors driving this trend include the increased demand for precision components in sectors like aerospace and automotive.

Sustainability is becoming a focal point in investment casting practices. Companies are exploring eco-friendly materials and processes to minimize waste. However, many foundries still rely on traditional methods, leading to inefficiencies and environmental concerns. Transitioning to greener practices remains a challenge for many in the industry.

The integration of advanced technologies like 3D printing and AI in investment casting is on the rise. These innovations can enhance production efficiency and reduce lead times. Nonetheless, many foundries face hurdles in adopting these technologies. The high initial investment and the need for skilled personnel can limit progress. As the industry evolves, addressing these challenges will be crucial for sustaining growth and competitiveness.